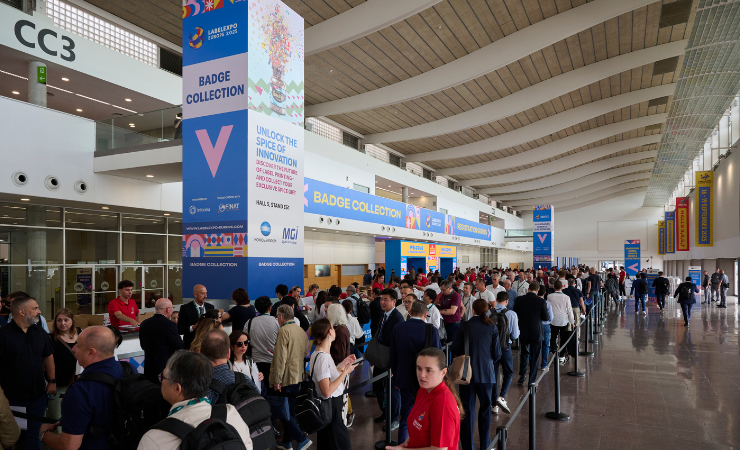

Labelexpo Europe took place from 16 to 19 September 2025 in Barcelona, bringing the sector to the Catalan capital for the first time. Despite some issues with air conditioning, the show was well received and emerged with a new name intended to highlight its diversification from a pure label focus.

The heat was on in Barcelona in September. Organiser Informa had moved Labelexpo Europe from Brussels after the 2023 iteration. Interest was heightened, and the industry was keen to experience its first show in Catalonia.

That 2023 event was bedevilled by sweltering temperatures, exacerbated by air conditioning problems at the aging expo venue. Such an uncomfortable combination would not happen at the vastly more modern Fira Barcelona, obviously.

Wishful thinking – as all those who spent time in Hall 3 would testify!

There had been no official public fallout about the situation at time of going to press, but the talk on the final day of Labelexpo Europe was of a meeting that morning at which numerous exhibitors were said to have voiced their displeasure.

Positive outlook

All of that aside, the official exhibitor communiqués released since the show ended have been universally positive. There were many new technologies launched, including a good few flexo or hybrid presses, and all this took place against a backdrop of increasing automation, AI integration and sustainability.

Lombardi Converting was notable for its launch of the Synchroline VIPER flexo press (VIPER stands for Very Important PERformance). Described as an “ideal solution for complex multi layer labels”, and with several integration options to enhance productivity and finishing capabilities, the VIPER was hitting speeds of 210m/min at Labelexpo, a speed that highlighted the new press’s enhanced register precision at high speeds, according to marketing manager Nicola Lombardi.

Mr Lombardi added that Labelexpo Barcelona 2025 was “an extraordinary experience in every way”, confirming how “vision and brand consistency can truly make the difference, turning a trade show into a real story of technology, design, and identity”.

On the Omet stand there was a new press for labels and packaging – the Omet K6, featuring interchangeable flexo units with sleeve technology, equipped with a renovated Cold Foil Saver unit which Omet says delivers up to 50% material savings on cold foil applications. The press has a vision camera system on each unit for automatic registration. The existing Omet X7 press was also shown with a new VisionX system for pre-register and register control.

Gallus introduced several new products, including the Gallus Five hybrid flexo/digital press (see page 33), and the company enjoyed what CEO Dario Urbinati described as “one of the most successful shows in the history of Gallus”.

Speaking to FlexoTech on the final day of the show, Mr Urbinati added: “There has been very good interest in coming to the show and our booth was very well visited over these four days. We have been able to present a new product range which got tremendous attention. It was important for us to show that.”

An engaged audience on the Mark Andy stage

Over at Mark Andy, many visitors flocked to see the Performance Series S9 flexo press, and the company’s CEO Duane Pekar stated: “The exhibition certainly attracted many high-level decision makers, and this has stimulated different conversations about what changes are needed from a leadership perspective. We view this exhibition as an excellent opportunity to build relationships and enjoyed keen interest in all our technology, but especially our Performance Series S9 flexo press and our high-speed DSHD flexo/ inkjet hybrid line that were making their European show debuts.”

Amongst other flexo press manufacturers, there was the introduction of a new EF Packaging Print Unit from MPS systems, which extends its EF platform into flexible packaging applications; Nilpeter showed its new FB-Line press for the first time and took customers to an open house at its nearby partner Esagraf to view the press; Edale had the new FL4E press, described as “high end performance but lower end for price”, as well as its CartonLine, based on the FL5 press.

There was considerable presence from manufacturers from outside Europe, particularly from China, with Brotech claiming to show the “world’s first AI-powered intelligent flexo press”, the FFX530. South Africa’s Rotocon, meanwhile, debuted at the event, showing its Chrome 450 press and Ecoline RSI 540 slitting, rewinding and inspection system; it reported more than 30 machines were sold in Barcelona.

Buoyant mood

Suppliers across the flexo prepress landscape were also in buoyant mood at the show and, indeed, afterwards. For example, James Steptoe, technical director at Troika Systems, which manufactures the AniCAM HD Plus anilox measurement device, said that his impression from Labelexpo Europe was of a dynamic and future focused event.

He commented: “The scale of innovation on display – from automation and digital printing to sustainability solutions – highlighted how quickly the packaging industry is evolving. Seeing the latest technology and recognising how companies are rethinking workflows, efficiency, and environmental responsibility was eye-opening. Moving forward, staying adaptable to change is going to be critical as we navigate newer technologies and methods.” Flexo plates and plate production were a focus with several exhibitors at the show.

Making its debut at Labelexpo Europe was a new XSYS laser imager for f lexo platemaking, the ThermoflexX Edge, which is due to launch in March 2026. Global communication manager Ozan Öztürk said XSYS’s goal is to “outperform everything on the market for speed and quality”.

It supports surface screening resolutions of 2400dpi and 2540dpi, using Woodpecker Nano screening, and delivers imaging speeds of up to 8.5sqm/hr. The imager can also be paired with the company’s EcoFillX software, which helps minimise solvent use and material waste during platemaking, and accommodates a range of plate types, including partial and thick plates. Initially to be launched as an 80-inch format model, both 60 and 48 size systems are to come later in 2026.

Vianord Engineering announced “the next generation of flexo platemaking” in the shape of its Freedom system, with integrated automation, intelligent process management and energy-efficient technologies. Also new are the Vianord Evo Line flexo plate processing systems, available in multiple configurations and incorporating LED exposure and Vianord’s patent pending Green+ drying technology.

Dantex unveiled Aqua X, a new generation of its Aquaflex water-wash plate processing range that brings “new levels of speed, efficiency and sustainability” to this field. Aqua X is converted for flexo from the Marathon, Dantex’s letterpress processing system. The company also reintroduced its improved PicoColour digital press, and CEO Ben Danon reported that Labelexpo Europe was a “tremendous success” for Dantex, with well-attended demonstrations from start to finish.

“Securing sales during the show was a real highlight, but equally important was the opportunity to spend time with customers, media and our distributor partners from around the world,” he said.

For Fujifilm, from a flexo perspective, water-washable plate solutions were the priority at Labelexpo, with the new FleneX Pro plate processor able to handle the also new water-washable FleneX Midori flexo plates, which are optimised for LED exposure and capable of up to 200lpi reproduction quality. Additional models in the FleneX Pro range are due to come in 2026, including a fully automated clam shell system, the FleneX Pro C. A new filtration system for plate production was also announced: FleneX Pure, which uses nothing more harmful than a household-friendly detergent. In addition, a new CuremaX ink range for flexo was launched.

Ink management solutions provider GSE launched Colorsat FCS (Formula Checkweigh System) in Barcelona, reporting strong interest in it from SME converters as an “affordable entry into professional ink management”. Marketing director Maarten Hummelen sees a growing awareness of how software and digital integration can help with automation, with the automation of colour preparation an example. “We can guide converters on the journey to fully automated, data-led workflows that are simpler, smarter and more sustainable,” he commented.

On the finishing side, ABG reported its “most successful Labelexpo in recent years”, off the back of the launch of DigiLase Duo, a new laser die cutting system. Global sales director Matt Burton said the show was a landmark event for ABG due to the new technology, sales and partnerships secured. “It was fantastic to welcome so many customers from around the world and the feedback and orders we received confirm ABG’s position as the trusted market leader in digital finishing innovation,” he said.

A new LOUPE

Thoughts already turn to the next iteration of the show, which in common with the entire Labelexpo Global Series will now be known under a different name, intended to convey the industry’s expansion and diversification towards flexible packaging and in-line folding cartons, alongside labels.

Therefore, when 2027 comes around – and, indeed, when what would have been Labelexpo Americas arrives in 2026 – the expo will henceforth be known as LOUPE – derived from the uppercase characters in Labels and OUter Packaging Embellishment.

Jade Grace, managing director of the Labelexpo Global Series, explained that the decision was made after “two years of consideration and consultation with trusted partners, industry associations and key clients”. She added: “Labels remain at the very core of the LOUPE portfolio, and we look forward to supporting the continued evolution of the industry.”

Anecdotally, the name change has inspired a mixed reaction, but let us end with a positive perspective, with Gavin Rittmeyer, VP sales and marketing at Martin Automatic, welcoming recognition of the changing scope of the broader label market. “We have seen this change for the past 15 years and often mused about when the label becomes another form of packaging,” he said. “With consumers demanding more from their packaging, broadening the scope of the expo into flexible packaging and folding cartons is a logical move.”

Masterpress talks hybrid and sustainability

Ultimately, it was not to be – but at the time FlexoTech sat down at Labelexpo Europe with Gabriel Magdaleno, Masterpress’s strategic product management & marketing director, there was a very real chance that the Polish label printing business would be named Converter of the Year at the expo’s associated awards.

Masterpress is a notable exponent of both hybrid printing technology and of shrink sleeve production. In terms of the former, it has worked closely with press manufacturer Omet over many years on the development of hybrid flexo-gravure press technology, starting in 2009 with an 11-station (ten flexo, one gravure) hybrid UV press.

Gabriel Magdaleno (left) with FlexoTech editor Andy Knaggs at Labelexpo in Barcelona

“We grew this hybrid philosophy a lot with Omet,” said Mr Magdaleno. “When we said we wanted a 15-station press with various options, they made it. They have been an important partner for this aspect.”

He added that other machinery manufacturers are evaluated when a new press investment is being investigated and revealed that Masterpress is to instal a new Mark Andy machine for handling pressure sensitive labels (PSLs) in the next few months.

Although Masterpress boasts several strands to its business, including machinery sales for shrink sleeve steam tunnels, dryers and applicators, and is looking into further diversification in areas such as flexible packaging production, its core product is shrink sleeves, which Mr Magdaleno describes as “a very good and clean labelling solution for recycling”. Sustainability is bound up in this perspective.

“It’s perfect; it easily comes off and all the contaminants go with it,” he continued. “Most shrink sleeves are not present at the point where recyclers have to wash off labels. In the shrink sleeve industry, we are working vigorously on trying to make sure that our products will perform and do their job at the end of life to help with recovery and recycling. It’s a non-adhesive label technology, and the contaminants go with it.”

Even so, with flexible packaging such a strong growth opportunity, Masterpress is considering a move beyond its narrow to mid web heritage into alternative flexo formats – that is a decision for the future though.