Well-protected sleeves cost a bit more but can save money in the longer term, impacting positively on areas such as press uptime, changeover efficiency and operator handling.

Flexo printers who doubt the importance of high-quality sleeves and adapters to their business, ought to take food for thought from reading the next paragraph.

“Sleeves and adapters typically account for less than 1% of a flexo printer’s total costs, yet their impact on the remaining 99% – including press uptime, job change efficiency, and operator productivity – is substantial. Investing in durable, well-protected sleeves reduces replacement frequency, minimises press disruptions, and supports smoother operations, ultimately delivering a stronger return on investment.”

The words belong to Gina Weinbracke, product manager at XSYS, which sells the rotec range of sleeves and adapters. It provides the perfect introduction for a discussion on the importance of sleeve protection, and how it can best be approached.

Sleeve replacement is typically triggered by issues affecting press runnability or print quality, such as tight-fit mounting, handling difficulties, poor registration, or inefficient job changes. Without proper protection or durable construction, sleeves and adapters can become a source of operational inefficiency and increased strain on press operators. Paying a little more for a sleeve with protection features built in would seem to be a no-brainer then.

Ms Weinbracke comments: “The cost-saving benefits of sleeve protection are straightforward. While the initial price of a sleeve or adapter may be higher, the overall cost across its extended lifetime is substantially lower. The real value lies not in the unit price, but in how long the product performs without needing replacement.”

Sleeve edge protection is therefore something that all flexo printers should be interested in. It plays a crucial role in extending product lifetime and maintaining consistent print quality.

“The sleeve edges are particularly prone to mechanical damage during handling or when heavy sleeves are placed on hard surfaces,” says Kuba Kostro, sales manager at Dantex Group Poland. “Once damaged, the edge can allow moisture, inks, or cleaning agents to penetrate the sleeve core, accelerating wear and reducing performance.

“Features like our signature rubber end and metal-reinforced notch combination aren’t just design choices – they’re proven innovations that protect the sleeve.” – Nick Vietnieks, Tech Sleeves

Features such as compressible end plates and reinforced and sealed edges help absorb impacts and prevent chemical ingress, Mr Kostro continues. This not only prolongs the service life of the sleeves but also improves sustainability by reducing waste and the need for replacements.

“From an ROI standpoint, investing in effective sleeve protection pays back through longer lifespan, reduced downtime, and lower overall maintenance costs.”

Small details

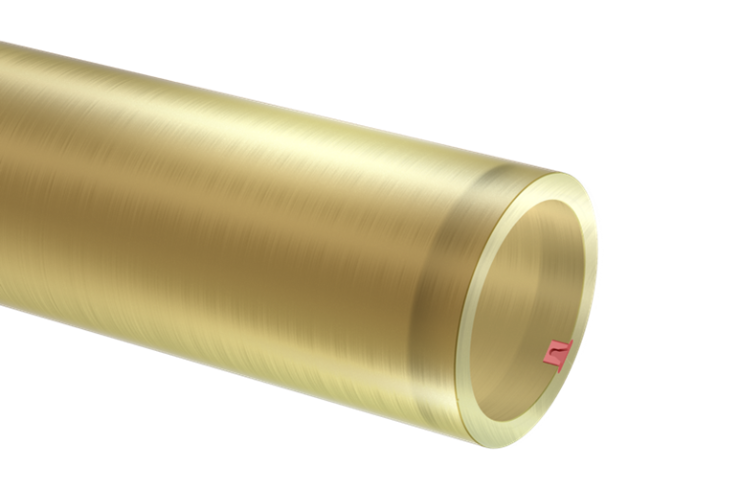

Among the leading sleeve suppliers is Tech Sleeves, whose general manager Nick Vietnieks points out that a standout feature on its Tech Standard and Tech Pro products is the rubber ends, which are “a small detail with a big impact”.

These specially engineered ends provide edge protection against decay, moisture, and chemical absorption, preventing the common problem of edge swelling that can compromise sleeve performance and print registration. By sealing off vulnerable areas, the rubber ends also extend sleeve life, significantly reducing replacement frequency.

In addition, these rubber ends can further reduce maintenance costs and downtime through protecting the mandrel or adapter pin, a part often damaged by rigid sleeve edges. Mr Vietnieks emphasises that “durability is at the core of everything we design”.

He continued: “Our flexographic sleeves are engineered to deliver long lasting performance, ensuring that our customers see real return on their investment. Features like our signature rubber end and metal-reinforced notch combination aren’t just design choices – they’re proven innovations that protect the sleeve, extend its lifespan, and provide unmatched stability during production.”

The stainless-steel notch, reinforced by the rubber end, ensures consistent, perfect registration, according to Mr Vietnieks – a design innovation that prevents the notch from loosening or slipping under pressure, meaning that “alignment remains flawless even at high press speeds”, and ensuring quality while reducing waste from misprints, with the obvious consequences for cost efficiency and sustainability goals.

Hermetically-sealed

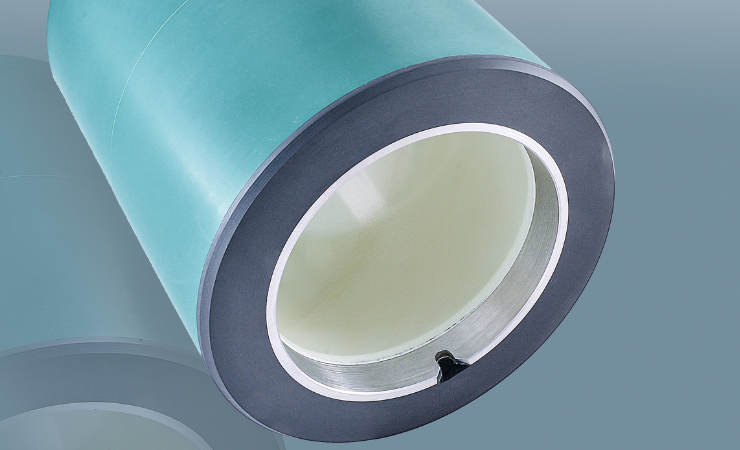

Also prominent in the flexo sleeve sector is Rossini, which highlights its StarCoat Light and EverGlass Light sleeves as having premium design features that ensure extended and sustainable sleeve life.

These sleeves are constructed with hermetically sealed fibreglass f langes at both ends, ensuring that neither liquid nor humidity can enter the internal structure of the sleeve, improving dimensional stability over time by limiting what Rossini says is the significant diametric growth commonly seen in entry level sleeves with open exposed side walls.

This also ensures that the flange will remain in place for the duration of the sleeve life, unlike, says Rossini, glued end seals which often fall off as the sleeve gets older and there has been solvent ingress into the seam between sleeve and end protection.

Starcoat Light sleeves additionally have a thin layer of conductive polyurethane in order to work in solvent-based printing. Rossini claims that both sleeve types are the only sleeves on the market with seamless end protection.

Rossini’s EverGlass sleeve

The addition of a fixed red polyurethane ring with register pin slot on the drive side adds further to the strength and integrity of the sleeve design and construction, protecting the sleeve edge from impact degradation, while protecting the press mandrels and the adapter’s register pins from damage and burring.

Another option that Rossini provides is its Anilox Protection Sleeve, developed from conversations with customers about their requirements for a safer, more robust protection solution. The sleeve has a slight internal taper so that when it is applied to the anilox it stops by interference only when the entire anilox is covered and therefore protected. The anilox cannot slip through the cover and, because the sleeve is slightly longer than the anilox, there is no risk of damaged ends.

Put a Ring on it

From the XSYS rotec perspective, there is a range of protective accessories and upgrades, including rings, guide-lines and end plates, that are designed to extend the lifetime of sleeves and adapters. Among these are the eco Xtra Ring and compressible end plates.

The eco Xtra Ring features a patented air distribution system that reduces compressed air requirements by up to 90%, enabling significantly easier mounting, according to XSYS. Its aluminium end ring construction also protects the adapter from gradual edge degradation, which is typical of standard polyurethane and carbon fibre adapter surfaces during repeated sleeve mounting.

Helping to safeguard the internal construction of the sleeve from environmental influences such as ink, cleaning solutions and humidity, the compressible end plates add further protection by absorbing impact forces during handling, thereby reducing the risk of mechanical damage to the base and edge – ultimately preserving sleeve performance and extending its usable life.

“The most effective approach combines high-quality sleeve construction with tight manufacturing tolerances and consistent implementation of best practices,” commented Gina Weinbracke. “Rotec sleeves are known for their durability, with some still in use after 15-plus years. Proper storage, cleaning, and handling routines can significantly extend product life. When paired with protective upgrades like end plates and eco Xtra Rings, these practices help maintain sleeve integrity and performance over time.”

Asked what other tips or best practice advice can be provided to reduce damage, improve press performance, and extend the usable life of sleeves and adapters, Ms Weinbracke offered: “To maximize sleeve longevity, printers should prioritise proper handling, storage, and cleaning procedures. Implementing protective accessories such as compressible end plates and eco Xtra Rings can significantly reduce wear and damage. Regular training for press operators on mounting techniques and sleeve care is also essential.”