Chamber doctor blade systems perform a quiet yet vital role in facilitating the highest flexo print quality, with ink pressure and doctor blade angles among key aspects of their operation.

No matter the market you serve as a flexo printer, it is very likely that chamber doctor blade systems play a key role in maintaining print quality within the operation. The demands placed upon such systems can vary depending on the sector you are printing for.

In flexible packaging, for example, the requirement is for tight ink control at high press speeds, enabling flexo printers to maintain fine halftones and minimise foaming. For those producing corrugated post-print, however, closed-chamber systems are needed to shield inks from dust and fibre contamination during converting. Meanwhile, label printers increasingly benefit from chamber systems when using UV inks, where viscosity and pigment load demand precise doctoring to avoid print defects like ink spitting.

What all these applications have in common though is that stable ink pressure within the chamber is the underlying prerequisite for predictable print results.

Ole Agergaard, technical director at AkeBoose, describes ink flow stability as “the quiet force behind consistent print quality”, and says the chamber doctor blade system “acts as the heart of the inking unit”. Its job is to help maintain a controlled ink film on the anilox roller, while minimising leaks, contamination and wear.

“In today’s flexographic printing industry, the ink circuit has become a critical focus for printers seeking both superior quality and sustainable production,” said Antony Whiteside, managing director at Absolute Engineering. “As demand grows for higher print consistency and lower environmental impact, many are discovering that upgrading their ink circuit is one of the most effective ways to achieve both.

“At Absolute, we’ve seen first-hand how a well-designed ink circuit can transform press performance. Consistent ink flow, controlled ink variables, and precise washouts all contribute to sharper print results and faster changeovers. More importantly, modern systems can significantly reduce energy use, water consumption, and material waste, helping printers meet both customer and environmental targets.”

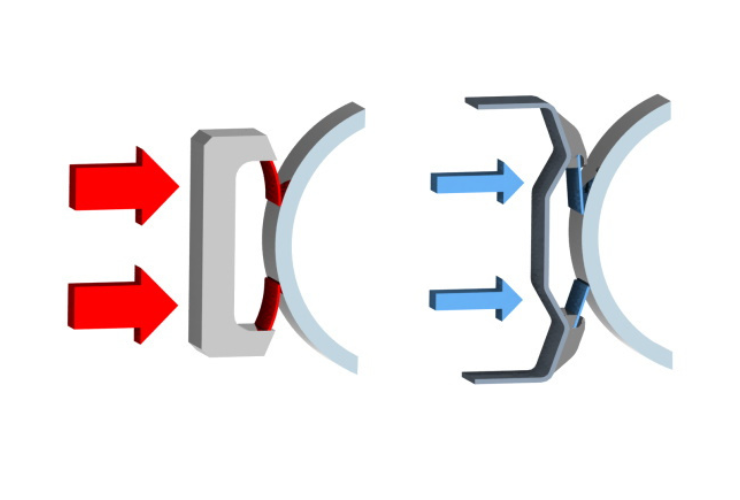

Illustration of comparative doctoring pressure on the anilox roller between symmetric (left) and asymmetric chamber systems (AkeBoose)

Harris & Bruno’s global marketing and business development for the Americas, Paul Fuse, explains: “In flexo, where precision and consistency are everything, the chamber is responsible for controlling ink pressure and flow so that the anilox roll receives exactly the right amount of ink, every time. This is what ensures a stable transfer and uniform coverage on the substrate.”

When pressure is not properly maintained, printers can face issues such as pinholing, foaming, or uneven ink density that compromise both quality and efficiency.

“A well-designed chamber system removes these variables by balancing ink delivery across the press width, keeping viscosity stable, and preventing excess aeration,” Mr Fuse continues. “For packaging printers in particular, this level of control is essential for meeting the demanding colour and brand requirements that major brands expect.”

He observes that chamber systems also play a big role in operational efficiency, reducing waste, extending press uptime, and making wash-ups faster by minimising ink contamination and foaming – which translates directly into lower cost per job and more predictable results on press.

Pressure control

The role of the chamber doctor blade system in controlling ink pressure is often considered to be critical. Søren Kristensen, global marketing & sustainability manager at Tresu, explains that a “simple but powerful principle” lies at the heart of the company’s pressure control system: an enclosed chamber system maintains precise pressure and flow conditions, preventing micro-foaming and ensuring a perfectly even print.

In addition, a long-life rubber seal creates an airtight environment that eliminates leakage and automatically sustains stable ink pressure. Within this closed loop, a liquid barrier forms between the rotating anilox roll and the chamber, preventing air from entering. The result, says Tresu, is smooth, high gloss coatings and blister-free prints, even at line speeds exceeding 600 m/min.

Mr Kristensen explains further: “The system’s precision relies on optimal blade positioning, proper chamber sealing, and an efficient ink supply circuit. In a twin-blade setup, the reverse-angle blade meters the ink while the trailing blade retains it in the chamber. Correct blade angles not only prevent air ingress and ink loss but also minimise wear, extending component life and reducing maintenance.

“Because the ink never comes into contact with the atmosphere during its transfer to the anilox roll, pressure and viscosity remain constant. This creates a stable ‘wall’ of liquid at the blade contact point, blocking air bubbles that cause micro-foaming and ensuring clean, uniform coverage.”

Another point made by Tresu is that the chamber system must also be complemented with a fully integrated ink logistics system to deliver consistent print quality. The combination helps maintain the balance between flow rate, pressure and viscosity, says Mr Kristensen, adding: “An automated ink supply continuously replenishes the chamber as the anilox roll draws ink into its cells. This closed loop design minimises waste, reduces manual handling, and ensures lean, repeatable, and predictable production – a cornerstone of high-quality, sustainable flexographic printing.”

Contact geometry

A slightly different perspective comes by way of AkeBoose, which acknowledges that in many flexo printing systems the pressure of the doctor blade chamber against the anilox roller is a variable to be monitored and balanced.

“In practice, however, pressure is not the factor that defines printing stability – it is the mechanical positioning and geometry of the chamber itself,” says Ole Agergaard.

He observes that when a chamber is pressed against the anilox roller with variable force, the contact line and the wiping behavior change depending on that pressure. This makes process control dependent on fluctuating mechanical conditions and printing speed, requiring constant pressure adjustments.

The AkeBoose philosophy is to f ix the chamber in an exact, stable position relative to the anilox roller, keeping the doctoring angle and contact geometry constant throughout the run, independent of ink pressure inside the chamber. The ink circulates freely through the chamber at near atmospheric pressure, ensuring, says Mr Agergaard, smooth replenishment and uniform transfer without the need for pressure regulation.

“AkeBoose engineers refer to this as the ‘Kiss Impression’ principle: applying only the minimal mechanical contact needed for effective doctoring, rather than compensating with pressure. This eliminates mechanical deflection, reduces wear on blades and seals, and avoids disturbances such as foaming or ink starvation that can result from fluctuating internal pressure and differing ink rheology.”

The UniPrint system from Tresu

The stability of ink flow is achieved not by controlling pressure, but by eliminating the need to control it in the first place, he explains. “The result is a The UniPrint system from Tresu 30 cleaner, calmer ink circuit and highly repeatable print results, even over long production runs, at high printing speeds or with varying ink viscosities.”

Modern chamber systems have generally moved on from symmetrical designs that resulted in “back doctoring” and ink leaks. Today’s asymmetric chamber geometries are optimised to control ink flow direction and minimise leakage. However, the performance of the seal remains a decisive factor, according to AkeBoose.

“Poorly matched materials or profiles can cause frequent ink loss, contamination, and cleaning downtime,” said Mr Agergaard. “Best practice is to use seal designs that allow the chamber to close with a soft but secure contact against the anilox surface; sufficient to prevent leaks, without excessive compression.”

Precision interface

In conclusion, chamber doctor blade systems have become highly sophisticated pieces of equipment – not a passive ink container, but a precision interface between the anilox roller and the ink circuit, as Ole Agergaard points out.

The emphasis on pressure control varies between manufacturers, with Tresu outlining the benefits to be gained from a sealed, pressure-controlled environment, and Mr Agergaard reiterating greater emphasis on achieving stability through geometry and positioning, which remains unaffected by viscosity changes or pump variations, saying: “True stability in flexo printing begins with mechanical balance, not pressure control.”