There have been Fogra standards for offset and digital printing for some time, and this year Fogra has come forward with a flexographic equivalent.

ProcessStandard Flexo (PSF) is a new attempt by Fogra to bring some standardisation to colour quality and consistency in flexo printing. The standard and its associated certification have been developed with the aim of streamlining production processes and enabling reliable colour communication between printers and clients, defining the requirements for production printing and proofing.

Jürgen Gemeinhardt, head of printing techniques at Fogra, explained: “The wish for the standardisation of flexographic printing came from the field. We have received many enquiries from all over the world. Print shops would like to have clearly defined rules and improved coordination processes with customers.

“The standard must be scientifically sound and represent the current state of the art. Above all however, it must also correspond to the reality in the printing industry. Fogra‘s network of print shops, manufacturers, and agencies is essential for ensuring practical relevance. Dialogue is the only way to know the needs, challenges, and current developments in the press room.”

Check the prints

Assessment and certification to PSF is carried out via a fingerprinting process, with the fingerprint serving as a reference, supported by an evaluation scheme that assesses achievable colour space and tone value reproduction. This guideline was developed in close collaboration with industry partners, said Fogra.

“Our goal is to make flexographic print quality measurable and to simplify communication between clients, repro houses, and printers.” – Jürgen Gemeinhardt

“Our goal is to make flexographic print quality measurable and to simplify communication between clients, repro houses, and printers,” said Mr Gemeinhardt.

The organisation emphasises that PSF has been developed to take account of the diverse requirements of packaging where, amongst other things, printing inks can be selected not just for their colour properties but also according to other criteria, such as light fastness. For that reason, the fingerprint, which serves as a reference throughout the workflow, and which determines the target values to be achieved in proof and production printing, is “given every degree of freedom” to account for the complexity inherent in the sector.

Mr Gemeinhardt added: “Except for special colours, Fogra will not specify any concrete target values in the PSF but define tolerances. The fingerprint is the reference that must be reproduced in production printing, within the tolerances and constant for the print run. The PSF will also contain an evaluation scheme for the fingerprint concerning colour characteristics.”

Clearly, at this point, the description of the process tips into highly technical territory, such that it cannot be usefully described on this page. The full guidelines are available from Fogra. What can be said is that the evaluation of the fingerprint includes the characterisation of the substrate or opaque white, alongside the classification of the reproducible colour space and of the smallest tone value.

Two to four weeks after fingerprinting is completed, a production run of a Fogra test form is carried out to determine adherence to the standard, with run lengths of either 2,000 or 3,000 revolutions required for inline narrow or wide web presses, and 5,000 revolutions for central cylinder presses. The certification lasts for two years.

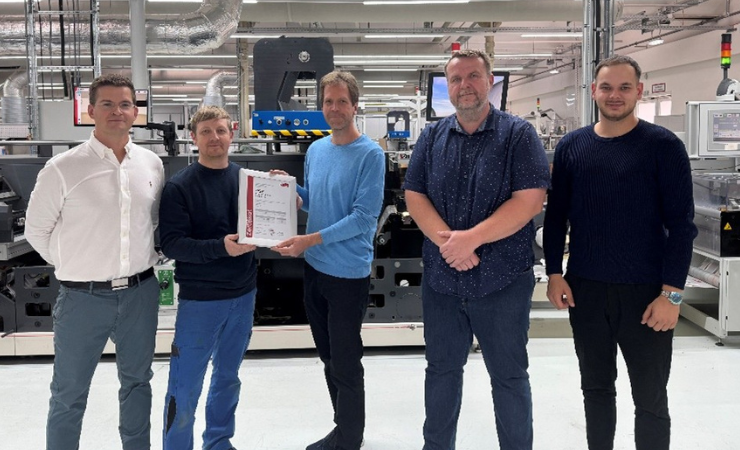

The first company to be certified under the PSF standard has already been announced: German print company Thüringer Papierwarenfabrik C Schröter. The decision to pursue the certification was driven by a desire to “improve our workflows, enhance internal and external quality standards, and increase customer satisfaction”, according to Torsten Dreke, managing director of the Mühlhausen company. Head of prepress Stefan Rößler added: “It saves costs, reduces our carbon footprint, and ensures customer satisfaction.”

Hi. Are there any changes to the density targets for CMYK when creating this new standard as latest UV flexo ink technologies with their high colour strength make it difficult to achieve Black 1.40-1.50, Cyan 1.20-1.30, Magenta 1.25-1.35 and Yellow 0.90-1.05. I’ve been asking the industry for a while but I’m not getting the answers.

Thanks.

Darron.

Print & Applications Manager ‘Edale’