Softprint TP-X is designed for increased daily job changeovers

With the flexible packaging market continuously growing, tesa has added a new plate mounting tape to its Softprint range.

Softprint TP-X is combined with FLEX-Design, which consists of a foam carrier embedded between two PE-reinforcement films. This results in a more forgiving laydown of the tape which helps to counterbalance the increase in sleeve circumference whilst achieving a better bonding on inconsistent surfaces through a specially-engineered adhesive.

By avoiding time consuming cleaning procedures during mounting and providing a reliable bond on even critical sleeve conditions, Softprint TP-X FLEX is adapted to increased daily job changeovers.

Negative reactions between ink residues and adhesives are avoided, providing fast plate mounting and demounting without the risk of plate damage.

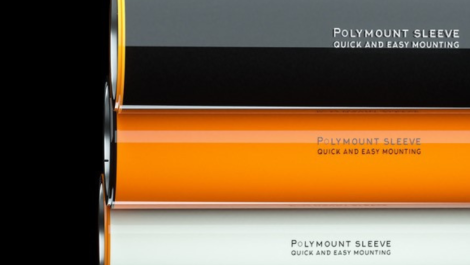

The new tape is available in four different hardness levels, with foams ranging from soft to medium, medium-hard and hard densities.

Richard Eeles, UK key account manager for flexo, said, ‘The combination of tesa Softprint tapes together with the latest plate technology and printing presses will enhance future print demands. Going forward, we are seeing a trend in the market to minimise the tape complexity and standardise product usage. As a result we are seeing more companies using the medium foam and medium/hard products to cover the majority of their print requirements.’