US repro company Pacificolor has bolstered its corrugated packaging capabilities with investments in plate mounting equipment and screening software. It said the new kit will enhance its production efficiency, with faster throughput and turnaround times, as well as enabling the production of bigger flexo plate sizes.

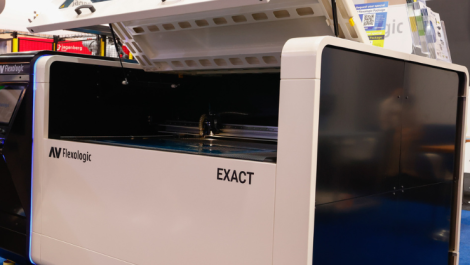

The $200,000 (€182,000) investment includes an AV Flexologic Corrugated Flatmount 3500 flat flexo plate mounting machine, which the manufacturer says can operate around 30% faster than a round mounter, using automatic HD cameras for quick and easy mounting.

Pacificolor says the system also integrates with its digital front-end architecture, which will lead to ‘innovative’ services that will simplify relationships with its clients. A key part of this is soft proofing, with the system able to create a composite PDF from scans of each separated plate, that can be shared with the customer for layout approval.

The screening technology is Reproflex3’s Vortex, an extension of Pacificolor’s partnership with the UK-based prepress supplier, which has already seen the US firm adopt Reproflex3’s Project Blue screening technology for flexible packaging.

Vortex has been created for ink on paper, corrugated and film, with tools that it is claimed stabilise the flexo print process to ‘create superior print consistently and cost effectively’.

Nick Brunk, chief revenue officer at Pacificolor, said the new AV Flexologic system will help deliver a range of new solutions for corrugated professionals in the box making and POP industries.

He added, ‘The combination of the AV Flexo mounter with Vortex will revolutionise sustainable printing solutions for corrugated packaging, delivering numerous advantages to cater to the evolving needs of converters and brand owners alike.’