Photopolymer plate formulators, manufacturers and suppliers, often receive enquiries on emerging technologies and their impact on flexographic printing plate development. UV LED technology may be the most established emerging technology today. MacDermid’s Ryan Vest looks at how the plate development and supply side of the fence, sees this technology playing out.

While the most common application of UV LED in flexographic printing today is often seen as the on press or print application area, the use of UV LED for curing flexographic plates has been around for longer than one may think. The use of UV LEDs has been most successfully applied via Esko in its Inline technology that combined plate ablation systems with UV LED curing technology – in this case, the plate could be ablated and cured on the same unit. While the combination brought about an advancement in equipment consolidation, along with solid print performance that was sustained over a period of years, a separate back exposure step was still required and the additional curing step resulted in a productivity bottleneck in this technology.

An additional application surfaced within the last few years, in which UV LED light sources were used in concert with standard fluorescent bulks to produce a flat top dot printing plate without the need for tying up your imager. The UV LEDs main function, in this case, were to outrun oxygen during the curing step, allowing for the formation of a flat dot surface, while the fluorescent bulbs completed the bulk curing process in the printing plate. While it certainly did isolate the curing step back to a separate exposure frame and away from the imager, a modified exposure unit was required, along with the need for multiple curing steps, thus the productivity and expense of such a unit may not have been ideal for certain segments of the market.

The most recent addition to UV LED curing is a full LED-based, standalone exposure system. Several of these have been publicised within the past two to three years, with one system receiving dominant praise in the industry to date – the Esko XPS Crystal system. This system allows for simultaneous, UV LED based curing on the back and front side of the printing plate, in a manner that is consistent in its application pass to pass, and plate to plate. This technology has also allowed for the introduction of a platform approach to platemaking automation, in which ablation to exposure, or further into plate processing, can be aligned together within a single production system.

Photopolymer interaction

Photopolymers are not moody nor highly intelligent autonomous creatures; they are mixture of chemicals designed with a class of behaviors and performance characteristics in mind, targeting a finished print application. They require many other technologies to be successful, exposure, washout, on press components, etc. Any variation of these components can lead to variation in the application of said photopolymer materials, and this includes plate exposure technology. The more widely variable the exposure technology, the more variation one can expect from your photopolymer photopolymer plate. This is where UV LED technology holds a distinct advantage; an unparalleled uniformity of light intensity across the width of the exposure device, which translates into more uniformity of the finished printing plate itself. More uniformity means more consistency, and more consistency lends itself to more repeatable and predictable finished results. This, simply put, was sorely needed within our industry.

There are additional areas of benefit relative to how UV curing is applied to the printing plate. In addition to supplying consistent and predictable amounts of UV energy to the plate- applying this is a consistent manner is also important. The ability to cure each plate the same way – meaning no differences relative to temperature, energy or even the time between the front side and back side exposures – these elements lead to greater and greater consistency. And with consistency, comes standardisation and predictability.

Considering UV LED technology and its growing impact, how do we, as formulators, deal with this technology? The ink formulators have borne the brunt of this emergence thus far – being forced to contend with reformulation efforts, new raw materials, functional differences, etc. On the platemaking side, there are essentially two possibilities we are forced to face: how do our current formulations interact with UV LED curing systems, and how do we modify or develop new formulations that take advantage of these light sources?

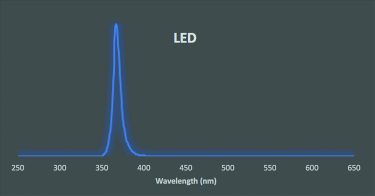

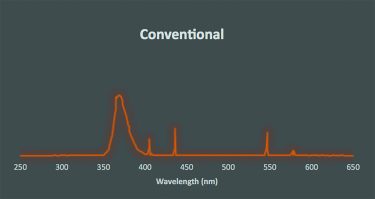

While the existing UV LED platemaking systems do target the same peak wavelength for curing, 365nm, UV LEDs are inherently near-monochromatic (see figure 1), ie a very narrow wavelength distribution, when compared to fluorescent bulbs (see figure 2).

As a result, photopolymer formulations that were developed with broad band bulbs in mind can quite possibly behave differently, and unpredictably, with these new systems despite their wavelength target similarities. To date, there are many formulations that have become qualified in these systems, so it is safe to say we, as the plate developers, have had a bit of serendipity with respect to the interactions between plates and light sources. There are, however, things that we have learned about along the way that will help guide us on where to go next.

Figure 1: Spectral output of LED exposure unit

Figure 2: Spectral output of flourescent exposure unit

Future developments

Future developments are not just because we can develop them – there are distinct benefits that are targeted specific to UV LED technology now that these light sources have become more readily available to test on and learn from. These benefits include:

Productivity: The current class of polymers in the market today have shown distinct differences in their behaviour under UV LED conditions. Generically speaking, the inherently flat top dot chemistries cure much faster under UV LED conditions, similar to their behavior under bank light conditions. With the benefits gleaned from the ability to control intensity with said systems, in combination with the uniformity of the intensity, there is new ability to focus on formulation speed without fear of losing control of the plate consistency. Future iterations of UV LED products can therefore be developed to best optimise the utilisation and efficiency of these systems without harming final quality. When combined with the automation aspect, this has intriguing possibilities for the platemaking facilities of the future.

Optimised cure/ performance: In addition to the monochromatic wavelength structure of UV LED systems, the other main difference in UV LED systems is the overall lamp intensity, ie it is much higher than typical bank light systems. As a result, the curing mechanism itself can radically change. This has been observed to occur with two main defects on the finished printing plate: inconsistent or unpredictable dot gain, and dot cupping. While certainly addressable via optimisation of process/curing conditions, the goal of new plate developments is to widen the platemaking window, allowing for a broader range of optimum conditions that are not impacted by slight changes in graphics, relief targets, print applications, etc the usual plethora of conditions that are dealt with by all of us in the industry.

Strategy

Within the MGS development and support team, our aim is to fully support UV LED technology as we truly believe this represents the future pathway of flexo platemaking. The reasons for this are articulated above, but we also feel this technology brings out the best in our photopolymer formulations. Similarly, we feel like we can continue to evolve our development programmes to further expand the capabilities of flexographic printing in combination with the benefits previously outlined.

To summarise, the gateway to UV LED will continue to drive forward because of three main elements:

• The outstanding uniformity of consistency of photopolymer plates derived from UV LED platemaking, and the print benefits obtained therefrom

• The ability to automate platemaking

• The increasing environmental pressures that will ultimately impact mercury-based light sources that are found in the existing bank light systems on the market today.

It is a key plate technology strategy for MacDermid to be prepared for this technological emergence and adoption, rather than waiting for it happen. By working very closely with the suppliers of the UV LED technologies, our platform strategy is focused on two areas of strength:

• High qualify formulations that exist today, qualified and proven to work in UV LED systems. These include resins such as Digital Rave and ITP 60.

• Newer technology platforms that are developed to be tuned to UV LED light sources, providing even greater productivity and wider performance latitude than plate technologies that currently exist.

By combining our formulation expertise with outstanding collaborative partnerships, we feel that we can help drive this technology not only to full adoption, but to greater and greater capabilities for our industry and customer base. Improved quality, productivity and efficiency – areas that will help drive more market share towards flexo and away from our competing technologies – while continuing to maximise profit along the way.

Hi sir,

Your article about photopolymer is very helpful and appreciable ,kindly which chemical is suitable to wash polymer after exposing to bring nice image

thanks