Delpro’s doctor blade chambers

While the function of the doctor blade may seem insignificant, it is not advisable to try to save costs by buying inferior products. Stopping the press just to change a worn blade makes no financial sense. By Neel Madsen.

As one of the many cogs in the flexo printing machine, the humble doctor blade works in unison with the anilox roller to get the ink onto the printing plate. While the amount of ink is determined by the volume of the anilox roller, the doctor blade ensures a clean and precise transfer takes place. Whether situated in a chamber or mounted in a single bladeholder, it can be made from a number of different materials, including steel, hardened polymer or carbon fibre.

‘It is a necessity to be able to offer a wide range of doctor blade types since the needs vary from printer to printer, and also between printing methods,’ said Jonas Andersson, technical sales manager at PrimeBlade Sweden AB. ‘We also have to consider what inks are used, what type of product is printed and what substrates used when the best doctor blade choice is made. Another point to look at is the edge type, the choice of bevel, round, lamella or special edge. It is vital to choose the right one to achieve the optimal blade wipe and lifetime.’

Bill Warner, vice president, Allison Systems, added, ‘The most appropriate blade for the application can also vary from one print deck to the next. The white station will benefit from the performance of a long life blade, while the process colour decks may perform fine with a different blade. Ideally, blades for each deck are chosen so that none of the blades will need to be changed before the others.’ He further pointed out that the doctor blade holder and actuating mechanism must be well maintained and free of mechanical damage, excessive wear, or corrosion damage to ensure optimum performance.

Steely Swedes

Swedev offers a wide variety of doctor blades, which are divided into three categories: Reliability Offer, Improvement Offer or Premium Offer. In each category, the blade choice will depend on the wear resistance, corrosion resistance and printing quality demanded by the application.

All of the company’s products are based on steels with refined microstructures and carbide densities for an even wear-edge and reliable performance, consistent from batch to batch. For water-based flexo inks and varnishes, the stainless steel MicroNox II blade is the SwedCut choice for wear resistance, corrosion resistance and for good quality printing. A two-degree bevel tip is often chosen for stable wiping. For more demanding inks, such as whites and metallics, the refined and alloyed carbon steel M-Flex Plus blade is recommended for long runs, outlasting plain carbon steel blades by three-fold. This blade is also suitable for UV inks, where a stiffer and thicker blade (above 0.20 mm) is required to deal with the higher ink viscosities.

First introduced at drupa, MicroKote H7 has been developed for extra demanding applications where a decrease in friction is vital to eliminate lines in print and extending blade life, and where aquaplaning with very stiff ceramic blades gives wiping problems.

Swedev’s blades are available in radius edge, bevel edge and lamella edge profiles for best performance depending on anilox line count, speed, inks and printing requirements.

The portfolio of doctor blades offered by PrimeBlade ranges from the basic type 300 carbon steel blade, for short runs, to the long life 900 Nano III blade, for very long runs and highly abrasive types of inks. In between, the company also offers plastic, high-grade carbon fibre, stainless and micro alloy tool steel blades.

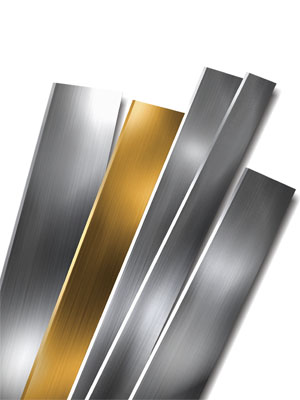

Doctor blade selction from PrimeBlade

The Swedish manufacturer introduced the 700 Series at drupa last June. This is a ceramic coated doctor blade, developed by combining PrimeBlade’s surface grinding and special surface treatment technologies to improve the coating adhesive bond and wear resistance compared to existing coated products. It is suitable for abrasive inks and wears down in smaller particles.

The high-grade steel together with the special ceramic particle surface coating technology offers a very low doctor blade tip contact friction, enhanced lifetime and gives a clean wipe. It also reduces the brittleness and cracking risk in the ceramic coating area, and lessens the risk of blade damage due to mechanical impact.

PrimeBlade also has the 900 Nano treated blade types, which Mr Andersson described as ‘a unique way of producing a long life doctor blade without using a coating.’ He said, ‘Instead we treat into the base material and change the steel structure. The treatment method increases blade life and reduces friction, and is an environmental clean way of producing long life doctor blades since no toxic waste products are created. The treatment procedure for the 900 Nano blades is a new process with vast possibilities, and the development is constantly ongoing, ie more products than today’s 900 Nano I, II and III will be released.’

Gold, white and blue

US-based Allison Systems offers White and Blue carbon steels, stainless steel, Gold long life steel and coated steel products as well as fibreglass and plastic doctor blades. Carbon steel blades are economical choices when used with short run process jobs on non-porous substrates and inks that are not very abrasive. They can be used on all anilox screens along with solvent, water and some UV inks. If corrosion is an issue, a stainless steel blade may be a better choice explained vice president Bill Warner.

Gold and Laser Gold long life steel blades are a good choice for use with abrasive applications or long runs. The blades are made from a tool steel alloy that wears in the form of a powder that can easily be flushed away from the blade. This is unlike other materials that can form wire burrs that break off as the blade wears and cause issues with print quality. A laser process can be applied to the working edge of the Gold material to further increase wear resistance. Gold blades can also help reduce anilox scoring issues.

Mr Warner said, ‘Many customers who are using our Laser Gold material report that it is very effective at reducing UV ink spitting issues. The Gold series blades are more expensive than carbon or stainless steel blades, but the benefits they provide easily justifies their added costs when compared to press downtime for blade changes during a run and scored anilox roller repair costs.’

The company offers four basic edge profiles for steel blades. The Allison Standard bevel is made with a nominal 15 degree bevel and provides the cleanest wipe of the four profiles. The Superhoned bevel is made with a nominal 4.5 degree bevel and provides the support and effective tip control of a beveled blade with a nearly constant contact area comparable to the lamella edge shape. The Rounded edge profile offer a precision, polished, rounded working edge at an economical price and Unhoned blades maintain the original rectangular shape of the

raw material.

Eurograv Limited is the UK and ROI distributor of the CBG Acciai range of doctor blades from Italy. Director Mike Attard said, ‘I strongly believe that the whole ink metering process is an area where big improvements to colour consistency and print quality can be achieved with the correct selection of doctor blade.’

He explained that CBG’s Wing Lamella profile has a much finer wiping area and will produce a more consistent colour throughout the blade life, whilst also improving the sealing of the chamber and the seals compared to traditional lamella or round edge blades.

Different coatings can be deployed to augment the Wing Lamella blades for use with special inks or printing extended gamut, where blade changes must be kept to a minimum. Customers have found that using the Super coating for standard colours with high line anilox rollers have printed up to 1.5 million metres without needing to change the blade.

In the chamber

Traditionally, chamber systems were most often used on wide web presses with a central impression cylinder, but these are now also available for narrow web presses.

‘Controlling ink flow is crucial for reducing waste and improving productivity,’ said Henrik Kristensen, Tresu Group. ‘Chamber doctor blades, in connection with a pumping system, are the key to control. They provide a fully enclosed means of ink supply, which allows the precise regulation of flow, pressure and viscosity, to ensure uniform and precise ink density at faster speeds.’

Tresu’s MaxiPrint Concept is a lightweight carbon fibre or ceramic chamber that comprises a chamber doctor blade, inking system and cleaning system. Suited for wide web and corrugated flexo applications between 1600 and 6000 mm, the concept offers corrosion resistance; fast, automatic internal cleaning; improved quality consistency and reduced ink loss. The company also has the FlexiPrint systems for narrow and mid web applications.

Absolute Engineering was established in 2000 and supplies woven carbon fibre, chamber doctor blade systems to the flexo industry. Last year, saw the company’s customer Interstate Container in the US upgrade three of their machines, incorporating Absolute’s systems.

In one machine, Uniblade was installed alongside the existing crossbar and loading system, while another machine was fitted with a 2G chamber. The third upgrade involved replacing the original rubber rollers, updating the drive and installing new 2G chamber-doctoring units.

Interstate noted a significant reduction in ink loss during colour change, a higher quality wash-up from dark to light and less downtime, resulting in higher outputs and improved quality print, following this upgrade.

Delpro will be showcasing its Ecoflex carbon fibre chamber doctor blade system at the ICE show in Munich this month. The system is suitable for solvent, water-based and UV inks and coatings, and can be retrofitted to any flexo press with web widths from 150 to 3000 mm. It can also be customised to meet the needs of specific applications, and a wide range of anilox diameters can be accommodated with alternative profiles available.