Evolution in flexo prepress services moves in different directions. FlexoTech looks at the supply of highly screened plates for flexo printing and the digital tools bringing automation to interactions with customers.

The provision of repro services to the flexo market continues to evolve, striving to meet the demands for quick turnaround and efficient delivery of plates that enable high quality flexo printing.

To meet such requirements, much thought and development is going into service provision: both the hardware and physical production of flexo plates, and the digital services and tools – both inwardly and outwardly focused – that are intended to automate and streamline the range of processes around plate ordering and production.

Elsewhere in the print world, much discussion has centred around “lights out” production, removing touchpoints where the need for human actions might lead to delay or error. Is that where flexo prepress services are heading too?

The situation is actually a little more complicated, according to Nick Mitchell, operations director at Contact Originators, who says: “It’s easy to look at ‘lights-out’ automation as the future of agile manufacturing, but in flexographic platemaking, it’s not that simple – and certainly not a one-size fits-all solution.”

Mr Mitchell sees two sides to automation: on the front end, he says, automation is already transforming how printers and brands work together. The company uses Esko WebCenter to deliver integrated approval flows and digital artwork management to its customers, bringing the benefits of fewer errors, faster approvals, and smoother collaboration.

“This is where automation excels – improving communication, driving speed to market, and reducing rework before a plate is even made,” he continued. “But when it comes to physical plate production, full ‘lights-out’ automation simply isn’t where it needs to be yet. While fully end-to-end automated lines might look impressive, when these systems fail, they don’t just slow things down, they can halt production entirely and force manual intervention at the worst possible moment.”

At Pulse Media, commercial director Chris Lane is certainly experiencing an increasing trend towards a need for a “lights-out” repro service, saying: “It’s definitely a reality. People like to order online and see where jobs are. If they are ordering a remake in the middle of the night, they like to see that it’s there, and when the next person comes on shift, they can see by logging online that it has moved through our production and it’s moving through the system. Rather than them chasing people all the time, we’re running a live production board for them. I’m seeing more and more that they want that live KPI information.”

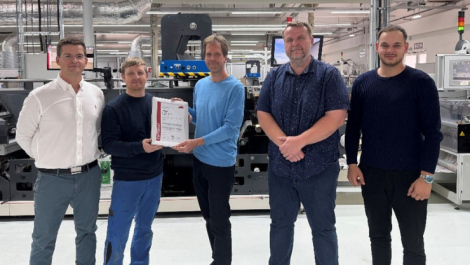

Contact Originators’ Nick

Mitchell: “We automate specific

parts of the process where it makes sense.”

Mr Lane says he sees that the power of these digital tools for ordering and customer interaction is only going to keep developing, and he says Pulse Media is looking to build Artificial Intelligence into the company’s online system going forward to help improve efficiency, and to expand the number of customers using the system.

In terms of the physical plate production line, however, full automation remains more problematic. The company uses Miraclon Flexcel NX platemaking systems, which require a laminating stage in creating a flexo plate.

“For me it’s about efficiencies. Rather than cutting the number of people down to the bare minimum, it is about actually working with people in partnership to improve efficiencies. I think that’s the most important thing going forward. Everyone is being challenged, but rather than working against each other, it’s about working in partnership with people to drive efficiency.”

Nick Mitchell at Contact says the business believes in a “modular, controlled approach” to the issue of automated plate production. He continued: “We automate specific parts of the process where it makes sense, and back it up with mirrored production lines for flexibility. This way, if there’s an issue, we can switch and pivot seamlessly to maintain delivery schedules and print quality.

“The ultimate goal isn’t just to replace hands with robots, it’s to build a strong, intelligent system that supports human expertise and keeps presses running smoothly. Automation should enhance reliability, not gamble with it.”

Screening

Turning now to the other trend identified at the start, the standards of flexo printing today are far in advance of what was historically possible. Achieving such standards is of course a balance of several factors, but a key one of those is the flexo plate, and a great deal is made today of the highly sophisticated screening technologies that can be packed into what might seem a simple piece of polymer.

In taking the temperature of the spread of these technologies throughout the sector, what comes through is that even those utilising them to make the plates take a fairly pragmatic view.

“Screening is increasingly talked about as the ‘ultimate game changer’ for print quality,” says Contact Originators’ Nick Mitchell, “but too often, it’s presented like black magic instead of the technical tool it really is. The reality is that all screening patterns have strengths and weaknesses. The best screening isn’t necessarily the most advanced or the most exclusive, it’s the one that works reliably across different presses, substrates, and inks.”

The company’s own experience (using solutions like Esko’s Crystal Screening) is that these excel not just because of theoretical image quality, but because they offer tolerance and flexibility. In large print groups with multiple sites or presses, being able to use one standardised screening method without needing to constantly tweak ink sets or press parameters is invaluable, he says.

Pragmatism certainly rules for Mr Mitchell, as he concludes: “Consistency beats everything. When it comes to screening, it’s not about chasing the newest or shiniest option. It’s about choosing what works, day in and day out, to deliver high-quality, predictable print.”

As a Miraclon user, Pulse Media has converted many customers over to the PureFlexo technology from that manufacturer. It also produces high volume sleeves with sophisticated screening for customers too, saving them lots of money on ink. Other customers are still using the more basic plates, but those on PureFlexo do so because they can see the efficiency benefits and ink savings that come with it, even if the plate is more expensive.

Chris Lane said: “Yes, it’s recognised as an expensive plate, but with the added benefits the NX plate and PureFlexo screening brings through efficiencies, increased productivity, quality, and reducing ink spend, we believe an extra penny per square inch on a polymer plate is a penny well spent. And at the end of the year, when totalling the square inches bought, we know that although other plates may be cheaper, in the long run, customers will be buying a lot more square inches imaged on a LAMs plate.”

Digitalising at Spirit

Packaging prepress provider Spirit Packaging Premedia has recently introduced improvements both to the way it produces flexo plates, and the online tools it offers to its flexo print customers, aimed at improving efficiency and transparency.

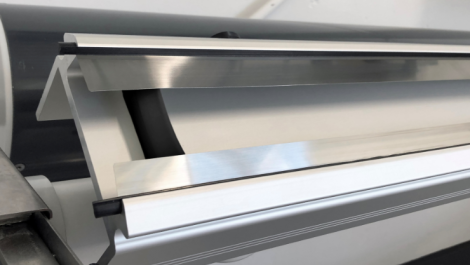

Spirit is using a one-step laser imaging process to expose precisely cut plate segments on a carrier film for corrugated

The company, which is based near Aachen, Germany, recently enhanced its production process for flexo plates used in corrugated packaging, using a one-step laser imaging process to expose precisely cut plate segments on a carrier film. This approach reduces material use and improves press performance, maintaining high print quality and registration accuracy, even in small polymer areas.

Soon to come is the Spirit FairPlate Online Shop, which will include the FairPlate Cost Calculator. The tool will allow users to estimate costs, place orders, and access technical data in a single platform. The shop is designed to be accessible around the clock and caters to both technical and commercial users, including customer service and procurement teams.

“Reprographics and flexo plate production are still largely manual processes – labour- and cost intensive,” said Mattijs Mennens, partner and chief operating officer of Spirit Packaging Premedia. “Our vision is to digitalise, standardise, and streamline both technical and administrative workflows – always with the goal of delivering real added value to our clients.”