Packaging and labels are being increasingly connected to the digital world through evolving technologies that deliver rich content and enhance operational efficiency. There could be opportunities for printers and converters in the world of connected packaging.

The results of an annual industry study released in February of this year showed that positive perspectives on the importance of connected packaging had reached new heights.

Carried out by the connected packaging agency Appetite Creative in partnership with Polytag and Digimarc, the Global Connected Packaging Survey (the fourth such) found that almost 89% of those surveyed (approximately 680 executives working across marketing, media, automotive, retail, utilities, construction, hospitality, FMCG/CPG and finance) believed that connected packaging will be important to the industry going forward. This had risen from just over 80% in the same survey a year before.

Jenny Stanley of Appetite Creative

And the survey noted technological shifts, with QR codes combined with NFC (Near Field Communication) emerging as the leading implementation method. Connected packaging is about integrating digital technologies into physical packaging to create interactive and informative experiences for consumers. What seemed like QR codes’ brief day in the sun several years ago has turned out to be just the start: the humble QR code has become a much more sophisticated tool today, capable of delivering rich, personalised content as well as providing operational benefits such as supply chain transparency and traceability.

“We’re seeing the connected packaging market mature, with companies taking a more strategic and sophisticated approach to implementation,” said Jenny Stanley, managing director at Appetite Creative. She added that sustained interest in serialised QR codes for connected packaging reflected “an industry that’s becoming more nuanced in how it engages with consumers and leverages technology for business value”.

The inclusion of Polytag as a partner to the Global Connected Packaging Survey is significant, in that Polytag develops “end-to-end” connected packaging solutions based on GS1 approved QR codes. Codes powered by GS1 include a GS1 Digital Link, which allows the product in the packaging to be linked to multiple online sources with enriched, real-time content – far more than the single URL that traditional QR codes would direct a user to.

Indeed, the “normal” QR code is being phased out. The Sunrise 2027 initiative intends that, by the end of 2027, retailers will have made their point-of-sale systems capable of scanning and reading both traditional barcodes and 2D barcodes. Also expected to become more important in packaging is the Digital Product Passport – a digital record containing comprehensive information about a product’s lifecycle, including its origin, materials, manufacturing process, and sustainability aspects.

GS1 transition

In the same month that Appetite’s survey results were announced, QR Squared was launched. Part of Polytag, QR Squared is a digital service designed to help brands to transition to GS1-powered QR codes. It gives them a “fully compliant, approved and secure platform to create and download Digital Link QR codes”.

The launch of this service was welcomed by Anne Godfrey, CEO of GS1 UK, part of the international not for-profit organisation that develops standards for barcodes, who said it “marks a significant step forward in transforming how we track, trace and engage with packaging”. She added that GS1 and Polytag had worked closely to “ensure that the platform meets the highest requirements for GS1 standards”.

GS1 itself has also been busy researching views and trends in the emerging field of connected packaging and published A new era of transparency in November 2024. This report explores the views of more than 500 UK-based leaders of retail businesses to understand the trends, challenges and opportunities currently facing the industry and where connected packaging currently sits among their priorities.

In penning the introduction to the report, Ms Godfrey referred to “the major transformation currently underway in retail”, driven by technical innovation, the rise of e-commerce, and shifting demands, behaviours and expectations.

“From consumers and regulators to brand owners and retailers, everyone wants to know more about the products they buy, sell or consume. However, space on pack is finite, meaning there will always be a limit to the amount of information physical labels can carry.”

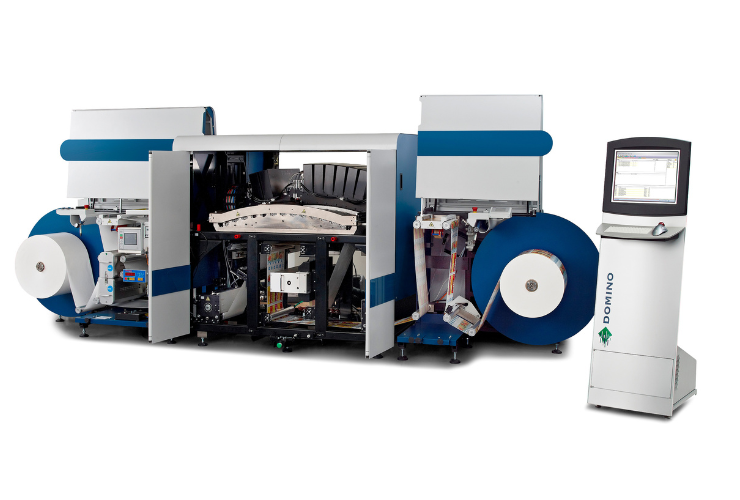

A key tool for connected packaging? Domino Printing Sciences’ N610i digital label press

Ms Godfrey went on to assert that, in GS1’s view, QR codes powered by GS1 will be a critical solution to this challenge. These next generation barcodes will “transform consumer engagement, enhance ESG reporting at both a product and a company level, improve traceability and transparency up and down the supply chain, and much more”.

The next chapter is a global transition from linear, one-dimensional barcodes to QR codes powered by GS1, she said, and GS1’s research was intended to ensure it had a complete understanding of the challenges QR technology can address and where these challenges sit among the retail industry’s current and future priorities.

“Our research has found that while the modern consumer has a thirst for knowledge, this need isn’t currently being met. Ninety-six per cent of those we spoke to agree that major change is on the horizon and that trusted data that informs and protects consumers will be at the heart of this transformation,” said Ms Godfrey. Nigel Allen of Domino: “Label converters have to be aware of this.” closely with clients such as brands on their packaging projects.

Inkjet options

Of course, these GS1-powered QR codes have to be printed, and digital inkjet is the most likely method for doing so, whether through a hybrid set-up as part of an analogue printing process, standalone digital mono overprinting on pre-printed stock or in a completely digital printing process in which the packaging and QR codes are printed digitally in a single pass.

Domino Printing Sciences is very active in this field, developing inkjet printing modules that are well-suited to this kind of work, and working closely, it says, with GS1 on influencing the advance of connected packaging.

Nigel Allen, marketing manager for 2D Codes at Domino, sees that beyond the specific production process, the big takeaway for printers and converters from this evolving field is the opportunity to work more closely with clients such as brands on their packaging projects.

“The label converters have to be aware of this because they will need to have conversations with their key customers, and it could change the way they deliver the packaging. So, the printers need to talk to the brand. The issue is that their usual point of contact may not be as aware of the latest solutions as, say, their colleagues in marketing. Marketing is often closely involved in project teams because of its longstanding experience of putting QR codes on packaging.”

Mr Allen identifies the increased use of data within connected packaging as being an important driver for printers to ensure they foster those stronger relationships with brand customers.

Nigel Allen of Domino

“The need for data provides another opportunity for converters to work more closely with their customers to strengthen the partnership, because there is a constant exchange about the data in the codes, code verification, and just in time production. Becoming more than a supplier, the converter plays an integral role in the overall success of the project. There could also be an opportunity for the converter to collaborate with a major brand, running an outsourced printing facility in-house at the brand’s factory, potentially running off labels as they need them.”

Any printer and converter working in the packaging and labels sector is increasingly going to be exposed to and engaged in conversations about issues around connected packaging: it is advisable that they ensure they are positioned take advantage of any such opportunities that might result in this evolving field.