Amberley Labels is one of the UK’s foremost label producers, with the technology and skillset to produce stunning, highly embellished labels, as well as flexo-printed “peel & read” labels. Andy Knaggs visited to find out what makes the business tick.

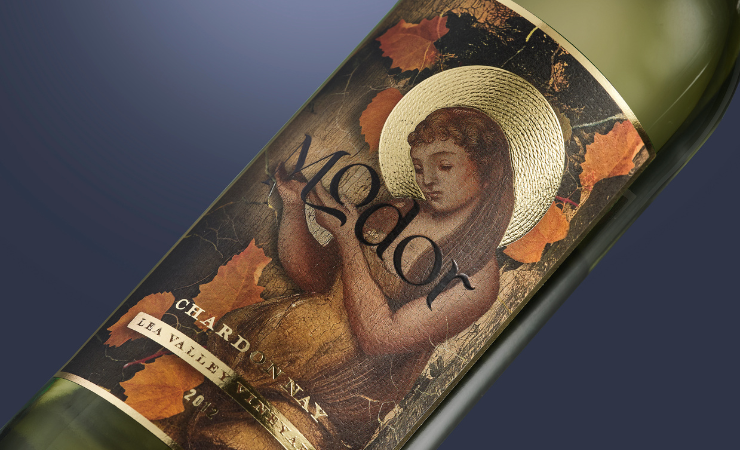

They make some beautiful things at Amberley Labels in Blandford Forum, Dorset, producing decorative labels with high embellishment for customers mostly in the cosmetics and fragrances sectors, and deploying some of the most advanced technology in the industry in doing so.

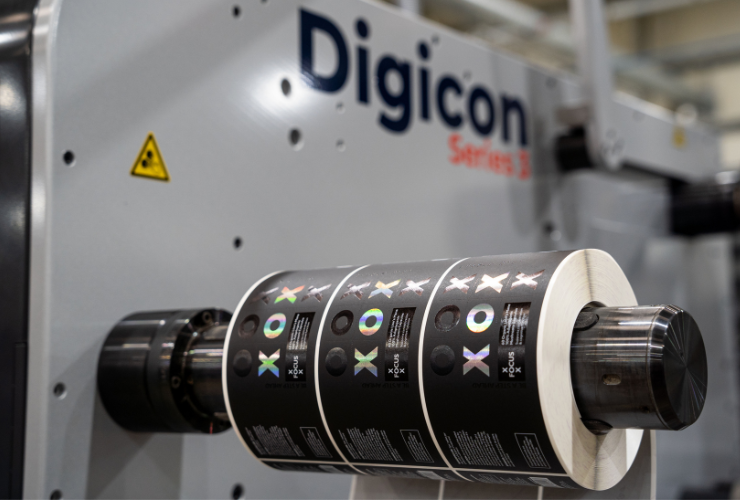

Part of Coveris since 2019, the 44-year-old business has invested continuously in printing and finishing systems. The majority have been digital, with three modern HP Indigo presses, but the company also has an Edale FL3 flexo press that is used almost entirely for crossover “peel & read” labels for products such as lipsticks and mascaras; further flexo capability is integrated within Amberley’s fleet of AB Graphic Digicon systems too.

Amberley’s latest ABG Digicon Series 3

Managing director David Richards says that 80% of the Dorset operation’s work is digital print, and 20% flexo; Amberley’s sister site in Boston, meanwhile, focuses more on long-run, high-volume flexo work, supporting a different mix of customer and product needs.

“The technological investment at this site has put us at the forefront of the industry,” Mr Richards told FlexoTech. “We have got every digital finishing capability in the market now, apart from laser cutting, and that’s thanks to Coveris supporting our need to invest in that technology.”

Most recently, Amberley in Blandford installed its third AB Graphic Digicon Series 3 converter – an integrated, single-pass finishing system capable of cold foil, hot foil, emboss/deboss and silk screen embellishments. It is equipped with a 50-ton “Big Foot” embossing module. Another notable installation at the business is unique in the UK: the first and still only Kurz DM-Jetliner (called Ecofoil at Amberley), which uses an “inkjet on foil” application method for digital embellishment and can run at 60m/min alongside the HP Indigo 6K press, foil f irst. This means Amberley only needs silver foil, as additional colours can be achieved by printing with the HP Indigo on top of the foil.

Quality conundrum

Producing highly embellished print work demands a different mindset to that found at most print businesses: an alternative conundrum between speed and quality control. Amberley Labels at Blandford has three quality assurance employees amongst its staff of 53 – an indication of its importance, says Mr Richards.

“There is much more quality control. The technical review of the project is much more front of focus where embellishment is involved, particularly because brands and design agencies build a concept but often it’s based on something they have produced on a carton, and they want something similar but on a different substrate,” continued Mr Richards. “The technical challenge is unique, placing high demands on both our team and our equipment to deliver exceptional results. But being part of Coveris gives us a real edge. We combine that high level of technical quality with the agility, integrated supply chain, and rapid lead times needed to get premium products to market fast.”

“While our processes are agile, many of the projects we support have inherently long lead times due to external factors, particularly when it comes to sourcing components like glass bottles or the product itself,” he adds. “That’s why some of our teams are already working on projects for Christmas 2026 and Mother’s Day 2027. It’s about aligning our capability to the customers’ expectations and that’s why we have important relationships with design agencies. One of the problems has been designers creating designs that don’t meet the capabilities of the equipment. So, we say: let us in from day one. With embellishment there’s a much more extensive list of questions to ask. We also have a training programme that we take out to customers, the purchasing people and packaging technologists, to talk about the importance of getting it right from the start.”

This commitment to quality control and the extra checks that Amberley Labels has in place is something that new machine operators often need to adjust to. It goes way beyond print quality and colour management; foils, silk screens, emboss/debossing must all be checked too.

“Because of this we invested in Fleyevision from AB Graphic,” said Mr Richards. “Labels are all checked to a golden image or PDF. Slitting is done in the rewind area, where we have flatbed scanners and Fleyevision. We print a lot of Mandarin, and as this is a language that our operators and QA team cannot check by human eye, we have to scan every single label to ensure that it’s reading correctly. We have lots of checks in place to meet different regulations and that’s what happens when you are a global supplier. We produce lots of small labels for cosmetics that go all over the world.”

Highest standards

Sustainability is an important focus for Amberley Labels too. The Blandford site has a Platinum rating from EcoVadis, alongside ISO14001, FSC and BRC AA+ certifications. The company’s customer base extends from new start-ups to major brands, and they all benefit from a supplier that adheres to the highest standards of environmental and operational excellence.

“With EcoVadis Platinum we are in the top 1% of label printers in the UK for sustainability and ethical trading,” stated Mr Richards. “It’s the leading industry auditor for sustainability and brands are now saying to people that if you are not at a certain level of EcoVadis, they will not trade with you. The Blandford site does not specifically serve the food sector, but we operate at food manufacturing standard here. We are audited every month by huge brands, and if you are BRC-approved, the audit process is so much better. It means that all our customers get the best quality of label.”

The commitment extends to working with customers to build a sustainability roadmap into their projects, looking to use the most environmentally friendly materials from the start, but with plans built in to continue seeking more sustainable alternatives going forward. “Being part of Coveris enables access to the widest range of pressure sensitive adhesives, so we have the power to access a wide range of materials and materials specialists to help us drive that sustainability roadmap,” said Mr Richards.

Flexo a must

The sustainability factor even comes into play with Amberley Labels’ Kurz DM-Jetliner, according to Mr Richards. The digital foil laid down is almost as thin as the HP Indigo inks, and he says Kurz has provided good data to show how sustainable its process is: the most sustainable foil machine on the market, it is claimed.

Looking ahead, Mr Richards is honest about the thought process for continued investment in equipment: it will be digital first, every time. This does not mean, though, that flexo will be neglected.

“There’s often a misunderstanding, but the beauty of a hybrid system is the flexo. The ABG Digicons all have flexo stations. I can print flexo and embellishment without going through the digital machine. So, it has to be digital or highly specified finishing equipment where flexo is a must as part of the spec of that kit. Customers want spot colours, solid colours and varnishes, and these need to be the last part of the process. You can only do that with flexo.”

Operations manager Dave Lovell (left) and managing director David Richards

An interesting direction for the business is looking towards data, software and automation, and how these can deliver efficiencies in its processes. Shop floor data collection is part of this, and Amberley has also installed the Batched software from Labeltraxx, which can group jobs together where appropriate. In addition, Labeltraxx’s Siteline online ordering system has been implemented.

These are intriguing moves for a business that is steeped in the high embellishment label world, suggesting that the quest for more efficiency is not confined to those chasing production speeds above all.

Mr Richards explains: “When you are creating beautiful labels that are printed and have hot foil, silk screen, emboss, cut in a special shape, it’s not straightforward. Pretty much everything we manufacture is a bespoke label and you cannot run the products we make at 200 metres per minute.

“But the small start-ups we serve don’t have the time that bigger clients do, and we have to offer them something really fast without compromising quality. That’s where online ordering comes in. It all needs to be done as fast as possible without compromise. These guys are moving so fast and if they get a big order, they need a very fast way to get orders through. That’s why we are investing in automation; to help best serve those customers.”