Pouches are proving to be a strong growth area within the flexible packaging field. It is, however, an application that requires printers and converters to pay considerable attention to the details.

From time to time while covering this industry, someone says something that really sticks in the mind. It was at Labelexpo Americas in Chicago last year, with FlexoTech in attendance, that Craig Curran, president at US label and packaging manufacturer Nosco, did just that.

He was describing the business’s journey into flexible packaging from its existing labels and carton printing base, and the challenges it had faced therein.

“You will need a lot of material expertise,” he said. “You have to learn all kinds of materials and learn them quickly. You need experienced operators. We were blessed to find a couple of guys that were good at laminating and slitting. Pouching – we had to learn the hard way. It’s really not easy. It was the school of hard knocks.”

The school of hard knocks indeed. A little later in Mr Curran’s presentation he made another memorable observation about quality control: “If you don’t test pouches before they go out the door, they will soon come back in the door. It can work for 50% of the run and something changes – the heat drops on the pouching machine, and you won’t have the right seal.”

He went on to explain the importance of building strong relationships with material suppliers, who know the laminations and the base materials. They can help with training too.

Challenges to success

With Mr Curran’s words in mind, FlexoTech spoke to two key equipment manufacturers in the pouch production sphere – Bobst on the printing and laminating side, which also develops barrier materials that might be used for pouch applications; and Karlville Swiss, which develops pouch making machines on the converting side, suitable for both digital and flexo printed output – to investigate how they see the challenges involved and how they are able to help printers and converters to be successful in this field.

For Bobst, application manager Xavier Bonamour said stand-up pouches with a robust bottom gusset that ensures each pouch stands upright on shelves are a key area of growth. This is driven, he added, by factors such as increased demand for packaged foods and beverages, and a rising preference for practical, convenient and sustainable packaging that is easy to store at home.

Pouches come in many different shapes, sizes and formats

Asked about the technical considerations that printers and converters must keep in mind for producing pouches compared to other flexible packaging applications, Mr Bonamour commented that the key considerations include the selection of raw materials and the converting processes. The selection of raw materials depends on factors such as product type, desired barrier properties and sustainability goals, with PET, PE, PP, and sometimes aluminum foil, paper-based or bio based materials being commonly used.

He continued: “Selecting the converting process for stand-up pouches depends on factors like production volume, desired features, and the type of material used. Factors such as heat resistance – especially in the sealing area – the sealing strength itself, and stability of the eye mark distance, will impact the machinability of the pouch in the converting process.”

The selection of materials is also important for issues around quality control and converting to form and seal the pouch, he said.

“To ensure the highest quality, it is important to pick the right raw materials for your product, and to ensure quality at every stage of converting. Testing the coefficient of friction for example is crucial for packaging, ensuring the product can withstand transportation challenges and provide the desired user experience. The eye mark distance is crucial for guiding machines in precise pouch cutting and sealing. It’s about getting it right at every step.”

With sustainability being no less of an imperative in pouches than in any other area of flexible packaging, printers and converters need to consider this aspect of material selection alongside the technical challenges that such substrates can pose. They might, for example, have lower thermal resistance and different mechanical properties compared to traditional materials. In addition, said Mr Bonamour, it can be challenging to achieve proper barrier properties – a field that Bobst has significant experience in, having developed its oneBarrier sustainable solutions alongside other industry partners.

“We can support converters in this area, for example with the coating and vacuum metallising processes for sustainable packaging,” added Mr Bonamour.

Converting complexity

Equipment manufacturer Karlville Swiss has developed KS-SUP, a modular, compact range of pouch making machines tailored to converters entering or expanding in this space for pouch converting. It is seeing continuing and surging demand for flexible packaging, with sustainability, e-commerce, and the need for premium shelf appeal among the key drivers.

“Many converters are exploring how to enter the pouch production market,” said Gustavo Guzzi, sales & marketing director at Karlville Swiss. “While the opportunity is substantial, the transition comes with its own set of challenges.”

Amongst the key challenges that Karlville Swiss identifies for converters are those around material complexity, short runs and fast turnarounds, workflow integration, sustainability compliance and capital investment and training. It explains these further:

- Material complexity: pouches often require multi-layer laminates, mono materials, or paper-based substrates; each has unique sealing, cutting, and handling requirements.

- Short runs and fast turnarounds: brands increasingly demand customised, short-run packaging with rapid delivery; this puts pressure on converters to adopt agile, efficient systems.

- Workflow integration: managing print registration, lamination, inspection, and pouching in a seamless f low is essential – but often difficult without automation.

- Sustainability compliance: converters must adapt to recyclable and compostable materials while maintaining performance and cost efficiency.

- Capital investment and training: entering pouch production requires not just machinery, but also skilled operators and process know-how.

The KS-SUP range includes machines that are optimised for short to medium runs, supporting mono materials, laminates, and paper-based substrates. The company says they are designed for efficiency, enabling quick changeovers, with low start up waste and reduced downtime, making them ideal for converters managing multiple SKUs.

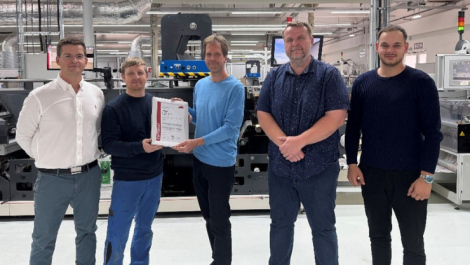

KS-SUP pouch making machines at Karlville Swiss

They can integrate seamlessly with both digital and conventional (ie flexo) printing workflows and offer flexibility for multiple formats such as stand-up and flat bottom pouches and side-gusset pouches, allowing converters to diversify within the pouch field. Karlville Swiss also facilitates the production of pouches with spouts, through providing single lane spout inserting machines with corner-cutting capability.

Right material, right equipment

Getting into pouch production is a strategic move for converters looking to stay competitive in a fast-evolving packaging landscape, and investing in the right equipment is clearly a critical aspect of successfully entering the pouch production environment. Gustavo Guzzi of Karlville Swiss concludes that the company’s machines enable converters to overcome entry barriers and thrive in this high-growth market.

FlexoTech asked Bobst what further advice it could give on making pouch production a success, and what pitfalls to avoid. “With our equipment, we can make sure that our customers can manufacture perfect reels to feed the pouch making equipment. We have vast experience across mid and wide web production with in-line flexo, CI flexo and gravure, meaning that converters can rely on Bobst, regardless of the printing preference choice or web width range,” said Xavier Bonamour.

Bobst’s Competence Centers are working on the development of sustainable packaging materials with the right barrier properties, he continued. “Together with our industry partners, we have pioneered the oneBarrier range of sustainable solutions, giving us years of invaluable hands-on experience of flexible packaging R&D in both mono material film and paper-based solutions.”