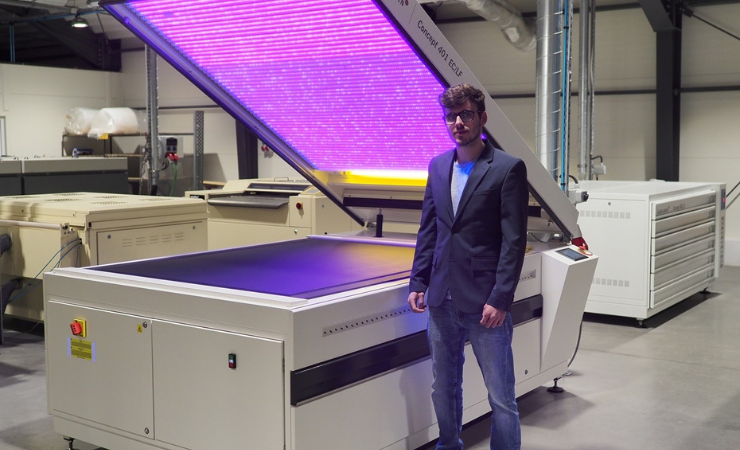

Polish flexo plate manufacturer, Fleksograf studio prepress, has become a beta site for Miraclon’s Shine LED Lamp Kits, installing the technology across two of its production facilities.

Founded in 2001, Fleksograf operates across two production sites, in Druzyna, Wagrowiec, Poland, producing flexo plates for European wide-web packaging customers on Miraclon’s Flexcel NX plate imaging systems. The company installed the second Shine LED Lamp Kit in February 2024, adding to the first installation in September 2023.

By utilising customers’ existing fluorescent exposure frames, the Shine LED Lamp Kit is a simple, cost-effective route to the advantages of LED, explained Miraclon. Benefits include consistent intensity over an operating life up to 5000 hours compared to 800 hours for fluorescent tubes, faster exposure times (by 20% or more), and enhanced sustainability due to reduced waste and less power consumed. On press, the increased plate consistency leads to more efficient printing, its claimed.

Providing customers with consistent quality plates is one reason for investing in the Lamp Kit, said Adam Malengowski, prepress manager of Fleksograf. ‘LED avoids one of the main issues with fluorescent tubes – the way they degrade over time, and at different rates. This means operators can spend a lot of time on process control, checking and recalibrating the tubes.’

He further explained that Miraclon’s option, the Shine LED Lamps, are ‘consistent over hours of production,’ between each lamp and within each lamp. Making it a ‘good solution for flexo platemakers looking to increase production efficiency by switching to LED exposure from fluorescent technology at a very competitive cost.’ Mr Malengowski added that LED lamps warm up and cool down instantaneously, meaning exposures are ‘significantly’ faster. Comparing LED’s main exposure time of approximately 12 minutes with fluorescent tubes’ 22 minutes, he stated that ‘productivity has been given a real boost.’

As early Polish adopters of Flexcel NX technology in 2010, adding a second system with Flexcel NX Ultra Processor in 2018, the company states that 100% of its production is now on Flexcel NX and Flexcel NX Ultra plates.

Mr Malegnowski highlighted the company’s use of the Flexcel NX Ultra solvent- and VOC-free plate processing technology as testament of its commitment to more sustainable plate production, another reason for the switch to LED. He concluded, ‘Energy consumption is lower with the Shine LED Lamp Kit, we don’t have the issue and expense of disposing of fluorescent tubes at the end of their much shorter life, and more consistent exposures eliminate defective plates. It all adds up to a more sustainable proposition for us and our customers.’