Bobst will introduce a series of new product developments at drupa 2024, incorporating systems for flexible packaging, labels, folding carton and corrugated.

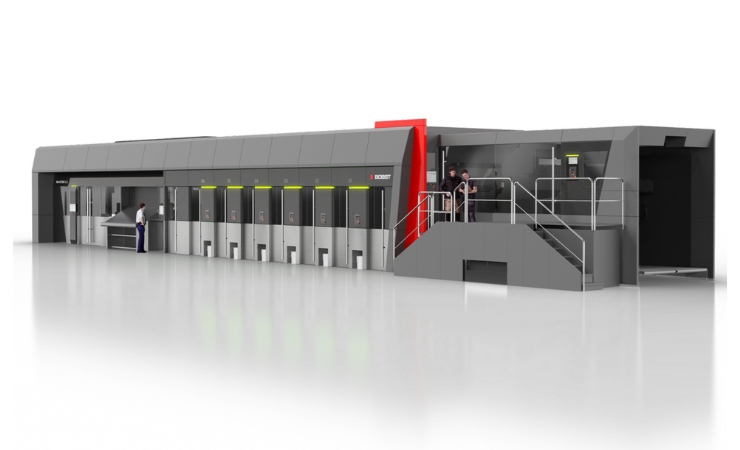

The company will unveil its Masterflex HD+, a new generation of the reference flexo printer, described as having ‘unmatched productivity’ and the ‘highest quality.’ By incorporating a new feeder, upstream pre-feeder and stacker outlet, the Masterflex HD+ can achieve a throughput of 15,000 sheets per hour. This enhancement results in an 8% boost in productivity.

A new FFG (flexo folder gluer) Extension will be unveiled at drupa 2024 capable of RSC (regular slotted carton) converting: printing (1/2 colours) and die-cutting with flexibility in production, robust design and short set-up time with top printer. A new Jumbo option enables upgrading from simple printer-slotter up to full line including stitching, taping and inline folder-gluer.

Also set to be shown is a new generation die-cutter, Expertcut 106 PER, which is said to increase performance up to 20% with an increased throughput and a positive sustainability impact. The Expertcut 106 comes equipped with new functions such as the Accuplaten, a new system that reduces the patching effort during setting and increased running speed.

With new elements of digitalisation, the Expertlam 900, a multi-technology coater and laminator, which is configurable in different forms, will also be present at drupa 2024.

The company will also share two new features for Bobst Connect, its cloud-based digital platform said to improve productivity.

Workflow with Job and Recipe Management is a feature explained to allow for seamless integration of Bobst machines into a customer’s production and design workflows, benefitting from bi-directional job and recipe data synchronisation for fast set up and increased productivity.

The new Energy Monitoring feature allows customers to measure their energy consumption and costs in real time. By collecting data across various jobs, settings and connected machines, together with the company’s Workflow and Automation Partners feature, customers can experience efficiency improvements and cost savings.

Bobst says that all new machines purchased in 2024 will benefit from at least 10% to 20% efficiency and productivity improvements, from reductions in waste, substrate, and energy usage.

Jean-Pascal Bobst, CEO of the Bobst Group commented, ‘Now, with an extensive portfolio of solutions that answer our clients’ needs, we can tailor our offering to them based on their evolving requirements over the years to come.’