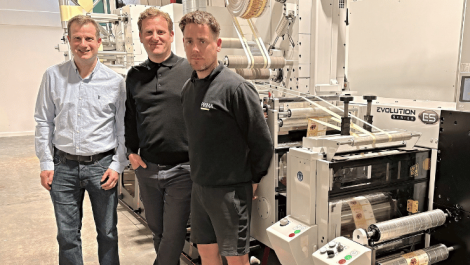

After operating an older generation Autobox box making machine for approximately 20 years, Dairi-Pak, an independent corrugated sheet plant, has installed a new Kobus Autobox AB300 to address its short run box making needs.

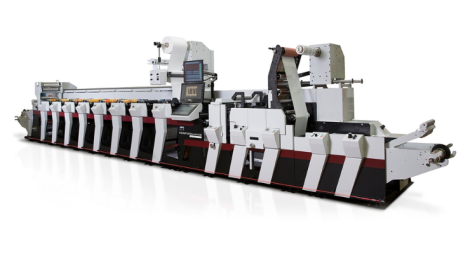

Recognising the increased demand for 0200 and 0201 boxes, trays, lids, and creased pads, managing director of Dairi-Pak, Tim Gray, decided to upgrade and add another machine, looking for quick set, big box capacity, in short and medium run length production. The Autobox AB300 box making machine installed comes with a flexo print station and impressed with benefits such as ease of use, simplicity of set up, and flexibility of the machine when producing both jumbo and mini boxes.

The new Autobox is a centre set machine for more accuracy at higher speed, and with more digital set up and full servo control over each panel for precise size settings. The wider machine has interchangeable slotting blades to cope with bigger boxes, and with smaller or more difficult panels.

With an easy, fast, and accurate set up, the flexo print station prints an area up to 1000 x 1000mm with a minimum repeat gap of only 350mm. With this in-line unit the door is opened to smaller run lengths, personalised box work and relieved capacity on the traditional higher volume machinery.

Arran Sethi, Kolbus UK director of sales said, ‘Autobox is a name synonymous with short to medium run boxmaking. We work with many sheet plants who want to offer exact sizes of smaller run length work. These jobs are often very big or very small, or made from a thin board grade, or a heavy one.’

Calling the Autobox AB300 an ‘extremely versatile machine’, Mr Sethi describes it as the ‘fastest short run boxmaker available,’ also highlighting the machine’s capabilities for larger runs. He added, ‘It can handle a sheet as wide as 2600mm deckle and unlimited length and can chop down to a 330 x 100mm blank size. With speeds as high as 1000 boxes per hour, the Autobox is not just for short run. We have customers making batches of up to 2000 units quite regularly, with margins upwards of 50%.’