RR Donnelley (RRD) has announced investment in four new flexo or hybrid presses for label production that it says will deliver faster throughput, greater efficiency and the flexibility to support its customers’ diversified needs. All four will be installed in sites across the US.

In addition, the business is also opening a ‘state-of-the-art’ label quality lab that it says will support clients by evaluating and developing products ahead of production. This will offer paper analysis, adhesive properties testing, accelerated aging and exposure analysis, printability and ‘most other testing procedures related to the label industry’, according to RRD.

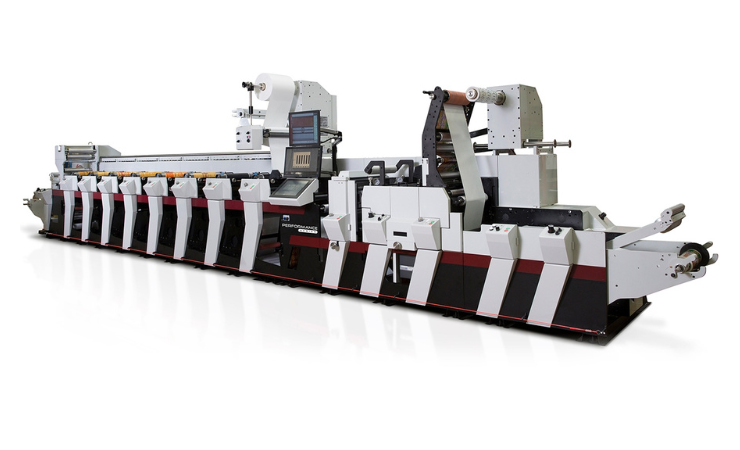

Two of the new flexo presses are ETI systems, which will be configured to vertically integrate face and liner papers to create pressure sensitive label stock. These will be joined by a Mark Andy P9 flexo press for variable image labels, and a Mark Andy digital hybrid press to serve clients that require more rapid turnarounds.

The context, according to RRD, is a booming ecommerce market, with sustained revenue growth of 51% predicted in the US between 2024 and 2029 (source: Statista). This will lead to increased demand for variable imaged labels, and the need for RRD to provide end-to-end offerings to clients of different sizes and locations.

‘Speed to market, high quality products and strong partnerships are important to our clients – we continue to keep those priorities top of mind,’ said Lisa Pruett, president for the packaging and label segment at RRD.

All four of the presses are expected to be operational by the middle of this year, while the label quality lab is expected to be operational by early May 2024.