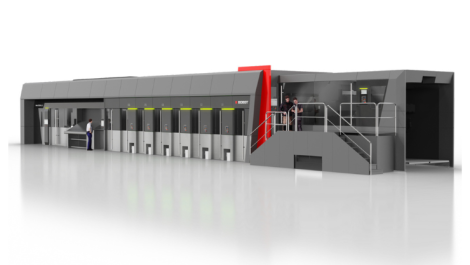

Advanced Packaging has installed a Baysek automatic die-cutter at its facility in Newcastle-Under-Lime.

‘We have always liked the Baysek die-cutter and its simplicity of use and quick job change overs,’ said director Carl Pender. ‘Robert Jess from Baysek took us to see a machine in production and we immediately knew it was for us.

‘The huge benefit of having this machine is the nick free, multiple-out die cuts which are perfect for our food packaging. On our previous machine the stripping on some jobs became more difficult and required additional and costly manual labour to strip the waste. Our new machine has eliminated this and we can now produce a lot more varied work and proactively acquire new business due to the machine’s substrate versatility and bigger sheet size compared to a traditional flatbed style machine.’

The unithas a maximum sheet size of 1400 x 1700mm and a maximum speed of 1800 sheets per hour. It is capable of die-cutting all grades of corrugated up to triple wall, solid board, foil/foam laminates as well as display board for the printing and display industries. Average job changeover is 10-15mins and running the machine only requires one operator.