Direct laser engraving is the latest addition to the offerings at Nägele in Germany

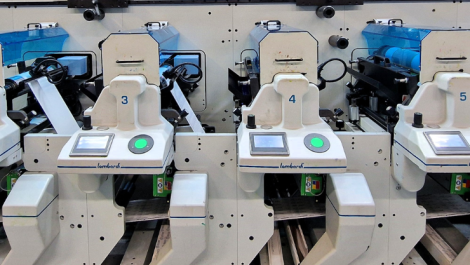

German repro specialist Nägele Digital Repro GmbH has recently extended its production capabilities with a Kodak Flexcel Direct System for direct engraving of elastomer flexographic plates and sleeves. With the new system, the company has acquired a direct engraving solution that is distinguished by its high resolution, productivity and outstanding versatility.

‘In addition to extending our underlying capacity, the Flexcel Direct System now allows us to manufacture high quality imaged elastomer plates and sleeves. For example, at screen rulings of up to 60 lines per cm, we can engrave a printable tonal range of 1% to 99% by modelling the dot edges accordingly,’ said Manfred Nägele, founder and senior director. ‘What’s more, it allows us to manufacture ester-resistant elastomer plates, as an alternative to special photopolymer plates, when two-component inks or varnishes are to be used during the printing process.’

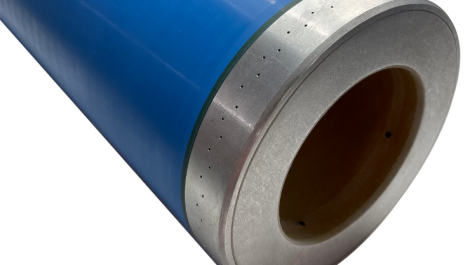

Nägele now supplies 10 different packaging printers of varying sizes with laser engraved plates and sleeves. ‘As far as sleeves are concerned,’ continued Mr Nägele, ‘the elastomer sleeves manufactured on the Flexcel System are of a higher quality than LAMS photopolymer sleeves. Another advantage lies in the fact that the delivery times for elastomer sleeves are significantly shorter and the purchase price is slightly lower. The sleeves stand out due to their excellent ink transfer and long print cycles. Using sleeves again opens up the prospect of significant savings due to the large reduction in set up times at the flexo presses.’

The new investment joins an existing array of Kodak technology solutions at Nägele, which has been using the Flexcel NX system since 2010. Driven by Kodak Prinergy workflow and equipped with hybrid options, both of the company’s NX Wide imagers are also able to image offset printing plates.

‘With the Flexcel Direct System, we have achieved a new quality level that was not previously possible in the field of direct engraving,’ concluded Mr Nägele.