It is expensive and challenging to use in production environments, but it is also often crucial in delivering vibrant flexo print. FlexoTech looks at the difficulties and the solutions around printing with white ink.

There is a simple statistic doing the rounds of the flexo industry that might raise an eyebrow or two: white ink typically accounts for around 50% of the ink cost for flexible packaging printers, and up to 65% of the total ink used.

These high proportions reflect the fact that it is critical to the success of most flexpack jobs. If the job is on transparent film, it is the white ink that blocks any colour coming through from the packaged products. On non white substrates and corrugated board, white ink ensures other inks reflect light in a controlled manner, keeping the colours true to the brand and making for packaging that grabs the attention on supermarket shelves. However, white ink is expensive – especially with escalating prices and pressures on the supply of key ingredients titanium dioxide and nitrocellulose (NC). It also brings its own challenges on production floors, including the abrasiveness of the ink itself.

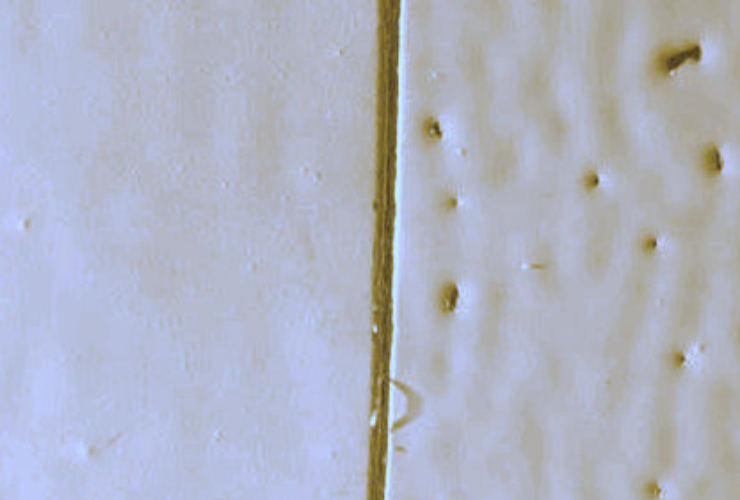

A strong, solid white ink layer without pinholes (which allow the colour below to show through) or mottle (light and dark patterns) is needed and defects in the opacity of the white coverage can make a huge difference in the print quality of the final product, no matter how well the process colours are printed. If there are problems with the white, the final result can be dirty, inconsistent or simply the wrong colour. Putting down a second hit of white might fill pinholes, but can compromise curing, press speeds and adhesion.

White workarounds

How can flexo printers tackle the challenges of working with white ink then? Traditional workarounds have involved either spending more money or reducing print capacity, or both, according to plate manufacturer Miraclon.

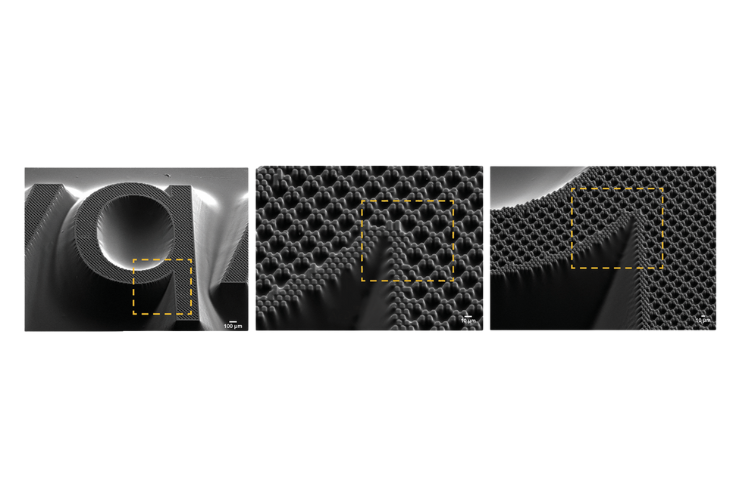

An image showing double form patterning (Miraclon)

John Anderson, director for Advanced Print Applications at the company, commented: “If a printer opts to tackle the pinhole problem by increasing the volume of ink, they not only drive up their consumables bill, but they’re likely to increase the drying time, which reduces productivity. If they opt to add extra ‘hits’ of white to f ill the voids, they’ll need to involve extra printing stations, which can introduce mismatches and consume 50% or more extra white ink. Which, again, adds drying time. Buying more expensive ink is another option. That comes with an obvious downside.”

Part of the answer comes in the plates. Miraclon says its Flexcel NX technology uses specially designed plate surface textures to deliver “highly effective and consistent” white ink printing. Multi-form surface patterning gives printers precise control over white ink laydown, enabling them to achieve target opacity with optimal ink efficiency, it claims.

“With multi-form surface patterning, printers can select the ideal solution to match their unique combination of ink, anilox, and substrate. This optimisation leads to enhanced on-press performance and productivity. And if any element of the printing system changes – whether that’s the ink, substrate, or the final application – they can simply pick the pattern that delivers the ‘sweet spot’ for each scenario and set up,” Mr Anderson added.

Optimal anilox

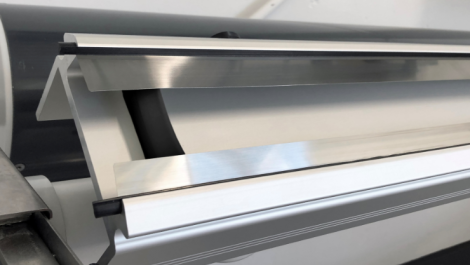

The nature of flexo printing means that the anilox roll will have a big role to play in tackling the challenges involved in printing with white ink. The abrasiveness of the white ink acts to wear down the anilox and Stuart Mitchell, technical director for print at Sandon Global says that a robust, high quality anilox coating can help protect against this wear, preserving cell geometry and performance.

Mr Mitchell observes that with NC-free ink systems being introduced, both to sidestep the supply issues with NC and to enhance the recyclability of the packaging being printed, these change the ink’s flow and transfer characteristics, placing fresh demands on the anilox, doctor blade and drying system to maintain opacity and print quality at speed.

White ink laydown with pinholing on the right (Cheshire Anilox)

Sandon’s response has been to tailor anilox solutions to specific applications. Its High Volume Process (HVP) engraving combines high volume with high line count to give wide web printers greater control over white ink laydown. The Fluid FP engraving is ideal for flexible packaging converters working with varied substrates or pushing their presses harder, often enabling two hits of white to become one. In UV flexo label printing, where the goal is screen-quality whites without the cost and complexity of screen units, Sandon’s High Opacity White (HOW) engraving was developed to handle the viscous nature of white inks.

Mr Mitchell adds: “An often overlooked part of white ink success lies in the interplay between the anilox and doctor blade. The appropriate blade configuration depends on the engraving itself, which is why we always recommend printers conduct combined trials to determine the optimal anilox and doctor blade pairing for their application.

“Opacity is the ultimate metric, but achieving it consistently requires a calibrated approach. Set your targets, measure accurately, and test thoroughly. Press hours are too valuable to waste on guesswork.”

Cheshire Anilox Technology also develops different anilox engravings for specific applications, including its easyflo HD for high opacity whites. The company’s managing director Sonia Arcos has written a multi- page paper on high-opacity whites in flexo, within which she revealed that using anilox rolls engraved to 60 degrees had been shown to result in extensive pinholing, while switching to a 30-degree engraved anilox saw this effect much reduced. The easyflow HD engraving is a 30-degree engraving.

There is obviously much more to it than this, and the Cheshire Anilox paper goes on to discuss substrate treatment, the ink, the printing plate, UV lamps, mounting tape and doctor blades.

To pick just one observation from Ms Arcos’s paper, she writes that: “Today’s laser technology allows anilox manufacturers to design high transfer engravings that are capable of evacuating the contents of finer cells efficiently. This means that high volumes of ink can now be transferred by a greater number of cells, improving smoothness of coverage, eliminating mottling and pinholing.”

Screen quality

Gallus’ Jonny Dörig success is based on “smart prepress choices”

To conclude – and with that statement about the goal being screen print quality whites in mind – it is worth getting a few words from Gallus too; a flexo press manufacturer that is also still developing its own Gallus Screen technology. Trying to match screen printing opacities often demands ink volumes well beyond standard specifications, said Jonny Dörig, head of product management.

“This increased demand strains both process control and cost efficiency. Gallus addresses this by aligning the relevant components, such as anilox rolls, plates, tapes, inks, and doctor blades, through deep collaboration with partners, ensuring maximum performance.”

He adds that even before printing, success is based on “smart prepress choices, such as pairing soft flexo plates with hard cliché tape, to set the stage for exceptional results”.

Printer’s view: Tony Rymer, head of print technical & development, Roberts Mart

At our company, white ink isn’t just a necessity, it’s a strategic focus. Like many packaging suppliers, whites represent the largest portion of our ink spend, driven by customer demand for full white backing coverage across surface and reverse print designs – even on white substrates.

Meeting specified opacity targets is non-negotiable. We’ve tailored our anilox inventory to hit these benchmarks consistently, and while some customers request dual white layers for added opacity, we typically recommend a single white backer to avoid long-run print issues.

Efficiency is key. We conduct regular mileage tests to refine white ink usage and keep costs in check, while rigorous anilox cleaning ensures consistent opacity and prevents plugging – especially critical when switching between substrates with incompatible white formulations.

Despite a busy production schedule, we always make time to trial new anilox screenings, plate technologies, and ink formulations with our suppliers. These collaborations have enabled us to achieve high-opacity whites using lower volume aniloxes, though we remain mindful of the quality challenges they can introduce.