Prepress group Miller Graphics has a strong presence in Europe and Africa, with its Limoges, France, site providing a specialised service in manufacturing and engraving elastomer sleeves for flexo printer customers. Andy Knaggs reports.

The city of Limoges in the Haute-Vienne department of southwest-central France is a place that is steeped in history: a Roman founding; a medieval siege and occupation by the English; and later, renowned porcelain and leather industries.

It has also been a historic hub for the graphics sector, and the place where a famous old name in French flexo from the 1950s – Clichés Bachkine – plied its trade. The same site in Limoges is now the location of the headquarters of Miller Graphics France, part of the Miller Graphics Group, which provides prepress, packaging design, print consumable supplies, and data and media management to brands and printers from 14 sites in Europe and Africa.

Of course, the Limoges site can deliver all the usual services that you would expect from a prepress provider – repro, artworking, photopolymer plates and plate mounting. But it has an additional specialisation too, one that has recently been boosted by significant investment in new technology.

Engraved elastomer sleeves are perhaps less heralded in the flexo sector as a way of transferring ink onto substrate, but in the hands of Miller Graphics it is very much seen as an attractive alternative to polymer plates. It is claimed that these sleeves can deliver high quality, with reduced set up times, and cost and environmental benefits for long runs and repetitive jobs, in comparison to plates.

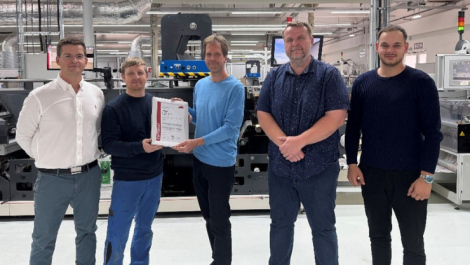

Miller Graphics has considerable expertise in making engraved sleeves for flexo production

Miller Graphics Limoges has been a hub for production of these sleeves for years, with an integrated supply chain that includes manufacture of the sleeves themselves at the facility. Its capabilities have had a major boost with the installation of France’s first hybrid Hell PremiumSetter D2000 3D laser engraving system.

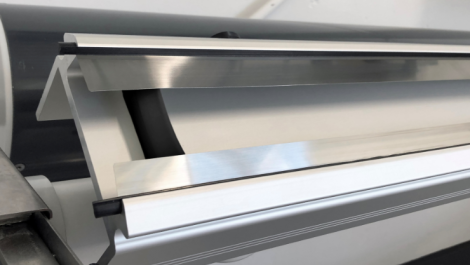

Capable of “high-definition quality” up to 5080dpi, this gives a 60% higher pixel density than standard 4000dpi systems, according to Miller Graphics. The 3D laser control enables the company to precisely adjust dot geometry (height, shoulder and base) according to customer needs, making it possible to minimise dot gain and improve ink transfer accuracy. The PremiumSetter D2000 can laser engrave sleeves up to 2m in width, although the Limoges factory can produce those up to 4m in width on an older engraving machine. The Hell system also has a hybrid capability, able to support photopolymer and elastomer plate imaging too, for applications requiring varnishes and aggressive inks.

With the new system comes a two-stage process of engraving and brushing of the rubber surface of the elastomer sleeve, which Miller Graphics says ensures sharpness in the screens, small texts and sleeve reserves. For the operators, there is a cantilevered swivel system that facilitates the installation and removal of sleeves.

“Engraved elastomer sleeves undoubtedly represent a promising solution in our industry, given that they can be reconditioned at the end of their life.” – Karin Hoga

These elastomer sleeves can be used with any ink types and substrates, and are ideal for high volume, repeatable flexo applications where precision and durability are required. Customer applications include flexible packaging, heat shrink sleeves, bags and pouches, hygiene paper and tissue, medical packaging and ruled and speciality paper, such as notebooks and pads. While there are three other laser engraving machines at Miller Graphics Limoges, the investment in the Hell system means the company can match any shape or size of dot that a customer requires, while testing new options and bringing them to market.

Karin Hoga, managing director at Miller Graphics France, comments: “This investment reinforces our leadership in laser-engraved sleeve production and supports our long-term strategic position in the UK, France and other European markets. By adding a new engraving unit to our laser department, we are increasing our HD engraving capacity and improving process efficiency. Engraved elastomer sleeves undoubtedly represent a promising solution in our industry, given that they can be reconditioned at the end of their life, which is a very attractive environmental solution for our customers.”

Reconditioning sleeves presents itself as an intriguing option for customers. Each sleeve can be returned, with external rubber layers removed, new layers possibly added, and re-engraving of artwork giving them several new leases of life. However, the heat used in the process does cause damage to the fibre glass core, leading the company to put a limit of three re-conditionings to each sleeve. Given the durability of the elastomer sleeves in comparison to a polymer plate, which cannot be re-conditioned, this still makes for a potentially compelling cost/ sustainability equation, the company claims.

Personalised approach

Yet sleeve production, as described, is but one of the competencies that Miller Graphics Group and its Limoges site bring to the market. A full range of prepress services is on offer, much as you would expect from a trade supplier, but the business seeks to find other ways of differentiating itself too.

“We work very much in a personalised way,” sales manager Jean-Hubert Archen told FlexoTech. “We test our printer customers’ machines, we know what anilox rollers they are using, and we adapt to the specific settings of their machines so we can go for the very best print quality for them, whether it’s corrugated, flexible packaging, tissue paper: the technical advice and personalised approach is really our added value.”

Consultancy and advice play a big part, and the business is proud of its ability to help customers – whether printers or brand owners – to find more efficiency and optimisation in their packaging production. An example of this has been its work with the food brand Findus, which saw Miller Graphics provide in-depth analysis and advice on reducing packaging production from six colours to four without compromising on quality. This was achieved with accompanying benefits in time and cost savings and reduced environmental impact through reduced ink usage and fewer flexo plates produced.

Miller Graphics can also help printers and brands with Extended Colour Gamut (ECG) printing, although it finds considerable variability in interest in this process from one region or country to the next.

“We are packaging experts,” says Ms Hoga. “Our transformation is now really towards digital services, helping our customers structure their packaging processes – that’s really the added value we can provide long term for our customers and brand owners.”

Key to this pillar of the Miller Graphics business is Atom Millnet, its internally developed cloud-based modular platform for managing collaborative digital workflows, images, product information, and colour separation control. The system has more than 2000 users, including 700 printer users.

Ms Hoga continued: “That’s the medium-to-long term transformation for us. But also, as a repro house, and as Europe’s biggest provider of flexo plates across Europe and Africa, it is important to keep investing in new CDI platemaking technology too. We look for the latest technologies; that’s how we can argue that it’s better for printers to use our expertise as a repro house. It’s a constant approach to investment.”

In conclusion, Philippe Bataillie, Miller Graphics Group president, comments: “At Miller Graphics, we support flexographic printers by continuously investing in advanced technologies for plate and sleeve production. By consolidating our elastomer sleeve expertise at our strategic production hub in France, we increased both capacity and precision to meet the growing international demand. This move strengthens our ability to deliver fast, reliable, and high-performance solutions to our UK and global customers. Backed by the reach of our international group, we remain a trusted and forward-thinking partner for the flexo industry.”