Brand implementation specialist Rivendell has achieved ‘best in class’ certification under the XPS Crystal Programme from Esko, in recognition of the consistent high quality of its flexo plates and subsequent print quality.

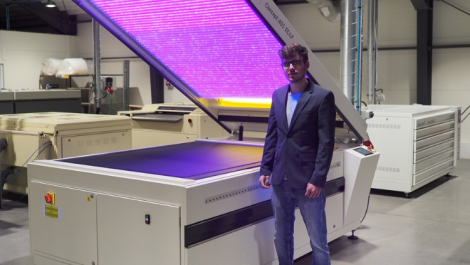

The Leeds-based company offers print and graphic support services, manufacturing its own plates at its in-house facility equipped with Esko 5080 CDI Crystal flexo plate imagers and XPS Crystal exposure units.

‘Using the large Esko CDI 5080 and XPS machines, we can easily make the highest quality plates for both our narrow web and wide web customers,’ said Lee Jones, head of graphic systems at Rivendell. ‘This certification from Esko enables us to promote an extra level of quality assurance to our customers, reassuring them that we always adhere to best practice in production processes and reinforcing their confidence in the consistent quality of the final print.’

Speaking on the advantages of using the XPS Crystal Mr Jones added, ‘The combination of the Crystal screening in Print Control Wizard together with the superior quality of the Esko XPS Crystal not only simplifies the overall platemaking process but also ultimately gives a better-quality plate. The resultant ‘perfect plate’ delivers improved ink laydown, better highlights and quite simply a better-quality print.’

The technology which combines UV main and back exposure, uses LEDs that emit consistent UV light. As a certified Esko partner, Rivendell now benefits from benchmarking and identification of best practice around quality control processes and production efficiency.

The LED technology replaces the need for fluorescent UV lamps contributing to a cleaner plate making process. The combination of Esko Print Control Wizard software, the CDI Crystal 5080 and the XPS Crystal 5080 also means Rivendell benefits from energy and waste reduction.

Mr Jones stated, ‘We benefit from fewer errors meaning less waste, solvent use reduction thanks to Solvent Saver in Flexo Engine, and the front and back LED exposure in the XPS Crystal means that we are using significantly less energy.’

The XPS Crystal Programme was developed by Esko to recognise those businesses that consistently produce premium flexo plates. Mike Ball, Esko’s sales account manager, said that Rivendell’s certification underlines their performance and is recognition of the company’s commitment to producing excellence in flexographic plates.

He further commented, ‘The XPS Crystal Certification Programme was developed to ensure the entire supply chain can meet the exacting needs and requirements of brands and converters in terms of predictable and accurate plate quality and the highest plate making consistency available, for any given photopolymer. Rivendell continues delivering to these highest of standards, and we are thrilled to be able to recognise that through this certification programme.’

The XPS Crystal recently achieved both Certified Energy Savings and Dematerialisation certifications from GreenCircle, an international third-party certification entity that independently verifies the validity of sustainability claims.