Bobst has announced increased sales for its Printing & Converting business unit in 2023, compared to 2022, reporting a rise of 7.9% to CHF 1.316 billion (€1.37 billion, US$1.49 billion). It said that the corrugated board industry was particularly strong during the period, followed by folding carton, labels and flexible materials.

The sales performance reflects a high machine backlog at the beginning of the year, and better availability of parts during 2023. However, orders for the Printing & Converting division were 30% below the previous year, which Bobst said was expected. It added that the backlog is now around 30% lower than at the end of 2022, but still higher than pre-COVID.

Printing & Converting reported an operating result (EBIT) of CHF 42 million, compared to CHF 47 million in 2022, with flooding at Bobst’s Firenze operation in November 2023 having a negative impact on this result. It said ‘ongoing initiatives to further improve efficiency and profitability’ will continue to be implemented.

The results for the Printing & Converting division are part of wider financial reporting from the Bobst Group, which the business categorised as ‘strong’. The figures show increased sales to CHF 1.960 billion, compared to CHF 1.841 billion in 2022, and an improved EBIT of CHF 147 million (up from CHF 141 million in 2022). Net working capital increased from CHF 113 million in 2022 to CHF 247 million in 2023.

Bobst Group said it was confident of ‘having another good year in 2024’, despite the overall economic situation and geopolitical tensions around the world. However, it said it expected its sales and operating result in 2024 to both be lower than those of 2022.

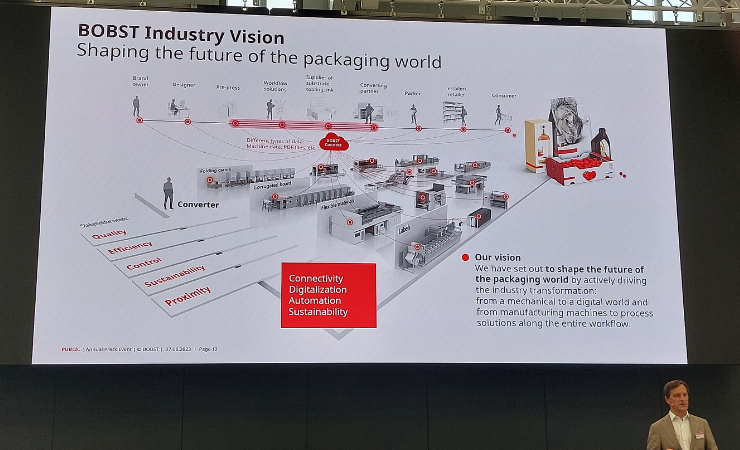

Its commentary regarding the outlook for 2024 stated, ‘As we look ahead to drupa 2024, our vision is continuing to progress at pace. Eventually, all the machines and tooling will ‘talk’ to each other, seamlessly transmitting data through a cloud-based platform orchestrating the entire production process with quality control systems.

‘For companies who embrace this approach, across the whole production workflow, more fact-based and timely decisions will be made, and higher productivity, higher efficiency and lower waste will be a reality. By drupa 2024, we will have even more proof points to demonstrate its impact and business cases.’