As the industry prepares for the return of Labelexpo Europe on 11-14 September, Bobst detailed some of the technologies that will greet visitors at Brussels Expo.

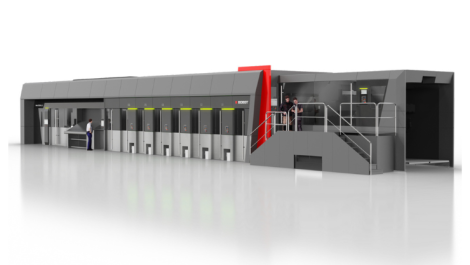

Under the motto ‘simplifying label production’, Bobst will be demonstrating its innovations in labels and flexible packaging production. The company is spearheading digitalisation, automation, connectivity and sustainability in packaging production with a portfolio that includes flexo, digital and all-in-one presses for a wide variety of applications.

‘Innovation in the label industry is shown at its best at Labelexpo,’ commented Matteo Cardinotti, general manager and global head of Bobst narrow and mid web. ‘New manufacturing technologies continue to support opportunities that simply were not available before, and we will see more of that at the 2023 edition. Bobst wants to welcome visitors on the booth to show them how we have the best solutions to the challenges they face in today’s market and for the future, and how we can help create new business opportunities.’

As converters face manpower shortages and demands for more sustainable options, Bobst will highlight unique automation features that can alleviate these issues. The high-end Bobst Master M6 flexo press will demonstrate how oneECG technology for extended colour gamut printing and V-Flower printing units enable fast, automatic changeovers of the printing cylinders without stopping the press and with only very minimal waste.

‘Labelexpo has always been a major milestone for Bobst, and for converters. For this edition, together with our partners, we will continue to shape the future of label production. We will take you across all the steps required to make labels better and more sustainable than ever,’ concluded Mr Cardinotti.