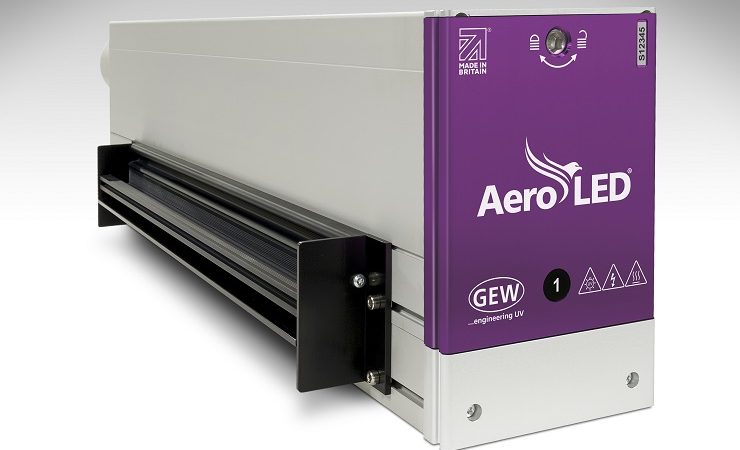

UK-based UV curing specialists, GEW has launched a fully air-cooled UV LED curing system for full cure, printing, coating and converting applications up to 60cm wide, AeroLED.

In an AeroLED system, the first significant innovation is in the air-cooling process. Cool, filtered air is distributed from a single centralised fan sited away from the press and exits through the UV lampheads, for quiet and reliable operation. The remote positioning of the fan avoids common problems caused by ink mist and dust ingress, while large air filters reduce the filter replacement cycle. There is no need for integrated fans or electronics in the individual lampheads, which eliminates the high pitched noise and contamination issues that these bring.

AeroLED features the same LED chassis and core components as GEW’s LeoLED lamphead, for proven reliability straight from launch day. AeroLED’s efficient optical design enables the lowest energy usage of all GEW products. This delivers energy savings of typically 50-70%, when compared to a conventional UV arc system.

In addition to the sustainability benefits of AeroLED, GEW highlight the ease of installation to those considering a retrofit upgrade. Robert Rae, managing director of sales at GEW, explained, ‘As AeroLED has GEW’s familiar E2C cassette design, upgrading an E2C system with RHINO/RLT power only requires switching to the AeroLED lampheads and the addition of a fan filter unit. All other components on press remain the same. This means that a retrofit upgrade can be implemented in as little as one day, and makes AeroLED the most cost-effective route to LED printing available, worldwide.’