GM has launched a new addition to its LC350 series, the Compact Laser Finishing unit which uses laser-cutting technology to replace traditional die-cutting and its associated tooling.

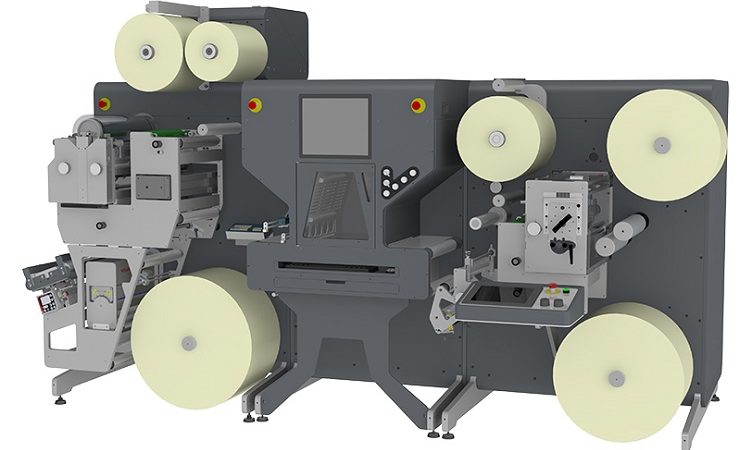

The LC350 joins GM’s expanding portfolio of converting lines that are capable of producing labels in a web width of 350mm. It is a compact laser finishing machine, which offers complex label finishing with varnishing and spot varnishing with the SmartFlexo semi-rotary module, as well as lamination, cold foil, web slitting and dual rewind. Other options include Corona treater, SmartSlit slitting module with automatic knife positioning system and a barcode reader for fast job change or quick recall of existing jobs.

Built on the foundation of its predecessor, the LC330, the new wider width LC350 Compact Laser Finisher has been equipped with more powerful laser heads, available in 250 and 350W versions. It features a new electronic platform and a larger touchscreen for easy operation.

‘By combining the latest laser cutting technology with a wider web width, the L350 increases productivity and meets the demand for faster delivery, especially of short run print jobs’, said GM’s CEO Uffe Nielsen.

Like all GM finishers, the LC350 can be supplied with full connectivity through GM’s VPN GATEWAY solution for remote diagnostics, service and support using a secure internet connection. This establishes access through the firewall of the existing wired network infrastructure to provide remote access for on-demand, real-time servicing.

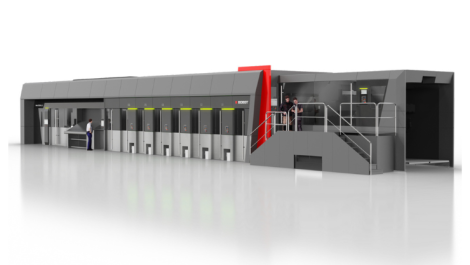

The LC350 works either offline or in-line with all major digital presses, offering label printers a versatile technology for low and high-volume digital printing. The laser module on its own can be also used in hybrid configuration and be added for example to the GM DC350 Fully Integrated Converting Line.