Label converter Firma Sigma has installed Russia’s first Mark Andy Performance Series P4 at its production facility in Moscow.

Sigma, which already has four Mark Andy 2200 presses, employs around 100 people and serves some 350 customers. It produces labels for the food industry, primarily for dairy products, and exclusively uses solvent-based inks.

‘We have had nine Mark Andy presses over the years and all have been extremely reliable,’ said owner Gennady Uzlov. ‘In fact our first 2200 is still running 24/7, and this gave us the confidence to stay with the brand and invest in one of its new P4 machines. It is well priced and is a very productive press – best of all it allows us to use the large inventory of 2200 tooling that we have built up over the years.’

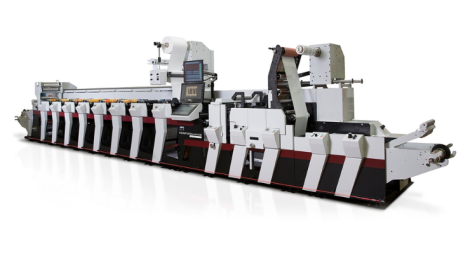

Mark Andy describes the P4 as a press that offers modern efficiency with enhanced flexibility. With a 60% faster changeover time than conventional inline presses, the modular design of the P4 offers responsive technology while its rail system allows each converter to customise applications. Available in three web widths from 280 to 430mm and capable of converting substrates from 50 to 305micron at speeds up to 230m/min, the P4 offers repeat lengths from 140 to 610mm.

Speaking for VIP-Systems, Mark Andy’s distributor in Russia, Maxim Aleksashenko added: ‘Sigma is one of three label converters serving this sector of the market in Moscow, and all are Mark Andy users. Present Packaging have 2200 and 4150 presses and TT Print have two P5s, so there is a strong belief in the productivity and efficiency of Mark Andy technology here – the presses allow their owners to make money in what is a very competitive marketplace.’