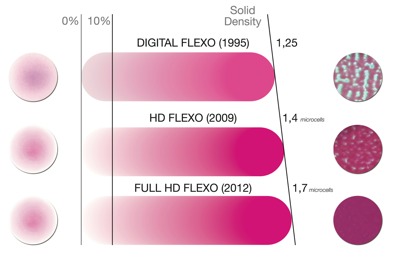

Obtaining the combination of smooth highlight printing and gravure-like solid ink densities for flexible packaging is now easier with Esko’s Full HD Flexo.

First introduced at drupa 2012, Full HD Flexo is today implemented in more than 20 flexo tradeshops and converters worldwide. The technology allows a digital flexo platemaking workflow with no analog steps.

‘Customers are asking for the combination of the benefits of HD Flexo together with a gravure-like ink laydown and a fully digitally controlled platemaking workflow. This is what Full HD Flexo brings and it moves flexo to an unseen level of quality and consistency with no need for compromises. Our patented technology stretches the possibilities of flexo printing, allowing it to perfectly match gravure and offset quality for flexible packaging,’ said Jürgen Andresen, vice president.

‘Since the introduction of HD Flexo, the high quality results achieved have created a growing demand for more packaging and labels to be printed in flexo. Also the proven sustainability and cost benefits contributed to the raising success of flexo printing. Now, Full HD Flexo will help to further accelerate this demand.’

The technology is capable of fine highlights, transitions to zero, sharp text and brilliant image details. It can add gravure-like solid ink laydown of the correct solid density, along with vibrant brand colours, platemaking consistency and a fully digitally controlled platemaking workflow.

The dot shape delivers a flexo plate suitable for the highlight, shadow and solid areas of a print job. Jan Buchweitz, senior product manager digital flexo, said, ‘We went beyond the binary discussion of flat top or round top dots, and created the best possible combination of print dot structures on one plate. This enables to differentiate the ink laydown on the substrate for different parts of the artwork on one single plate. This is a giant step forward for flexible packaging converters as the result is high quality flexible packaging that stands out. In addition, users report better performance of the flexo plate on the press for print consistency and printing speeds.’