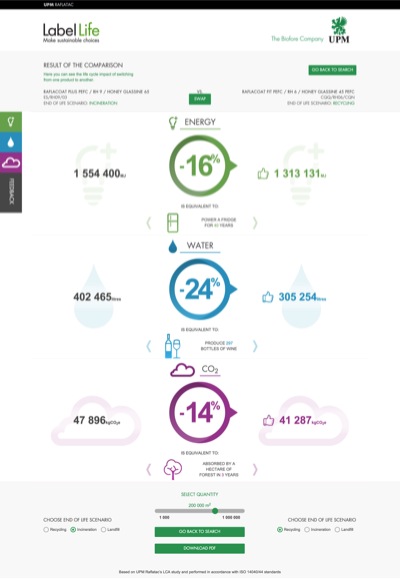

To help printers make sustainable choices based on a comprehensive life cycle assessment, UPM Raflatac introduced Label Life at Labelexpo.

The ‘Label Life’ concept is a new tool to help label printers and end-users understand the life cycle impacts of different labelstock products and get credible information on the environmental performance of their labels.

Based on the most comprehensive lifecycle assessment (LCA) in the industry, according to the company, the Label Life tool delivers reliable and easy to understand information to help customers make more sustainable choices.

Performed in accordance with ISO 14040/44 standards, the LCA helps understand the environmental performance of labelstock products in terms of carbon, water, energy and the end-of-life impacts of liner recycling. It has been developed in cooperation with PE International and is consistent with the methodology used by major brand owners to evaluate their own environmental impacts.

‘We have taken full benefit of our in-house expertise and capabilities to implement the LCA approach and understand the environmental impacts of the products we manufacture. Our holistic ecodesign approach takes environmental factors into consideration in both what we do and how we do it. The results of our LCAs transfer into practical actions, allowing us to best inform label printers and end-users about the environmental choices open to them’, said Robert Taylor, environmental director. ‘For example, the new Raflacoat Fit PEFC range offers up to a 17% reduction in CO2 compared to the older products.’

The Label Life tool compares substrates and shows the user what the differences are

The Label Life tool compares substrates and shows the user what the differences are

To really hit home with decision makers, the Label Life tool analyses the results and converts the measurements into a more visual statistic, such as comparing the energy saved to how many street lamps could be lit.

‘Choosing the right scope is critical to the validity of the LCA results. The reach of our LCAs includes the production of paper, film and adhesive raw materials, the labelstock production processes in our own facilities, transportation to customers, label conversion and the end-of-life scenarios for landfill, incineration and recycling. We are currently working together with partners to calculate high quality data for the label dispensing operations as well,’ concluded Mr Taylor.