Anilox rollers will only perform to their optimum level when cells are delivering the ink volumes expected. Anilox inspection is a critical process in ensuring quality flexo printing is maintained.

The acceptance of the need for inspection begins with understanding. Understanding that the performance of the anilox roller, the ink volume that it lays down, is the foundation of high quality flexo printing. Understanding that the way this is controllered and delivered is through the uniform cell structures on the surface of the anilox roller. Understanding that usage of a roller leads to wear of cell walls and structures and a build-up of ink residues, varnishes and other contaminants within the cells; that worn cell walls and structures and contamination have a direct impact on the volume of ink the anilox roller can lay down during the flexo printing process.

Ade Morton, sales director of Anilox Laser Technology, paints a simple picture. If colour of a mixed ink is not achieved, he says, then the first question to ask is, is it the correct anilox in the print unit? If it is the correct anilox, then the second question is, is the anilox clean?

“Inspection of the anilox is therefore of the highest importance as knowing the cells are clean allows the printer to then quickly ascertain the reason for colour not falling within the correct deltaE measurement and deciding quickly on the corrective action.

“The line/screen counts on anilox rollers have continued to increase to ensure better graphic reproduction of printed images. This has resulted in, typically, anilox rollers containing well over half a million cells and in some cases in excess of one million cells within one square inch. The size and structure of these cells is impossible to view without the correct inspection equipment.”

Case made

The case for inspection needs scarcely be made more strongly. However, it still needs to be emphasised that a half-hearted commitment to anilox inspection is not really going to put a flexo printer in a great position in today’s market. Increasingly, printers are implementing structured programmes and embracing data driven approaches to this critical area of their operation. Very often, they are working directly with their anilox supplier on such initiatives, while others are taking a firmer grip themselves, investing in the inspection technology and expertise to maintain their anilox inventories in prime condition.

Sonia Arcos, Cheshire Anilox Technology’s managing director, is seeing this happen. “The key to ensuring maximum performance from anilox rollers is implementing a preventative maintenance program.

This means not only ensuring rollers are thoroughly cleaned after each use but also tracking their essential data points,” she says.

“For example, before a job even starts, converters need to know if their anilox rollers meet the criteria they logged the last time that job was successfully produced. This includes measuring the volume of the anilox roller using equipment like a Capatch strip, ink drawdown tests, high power microscopes or interferometric cameras.

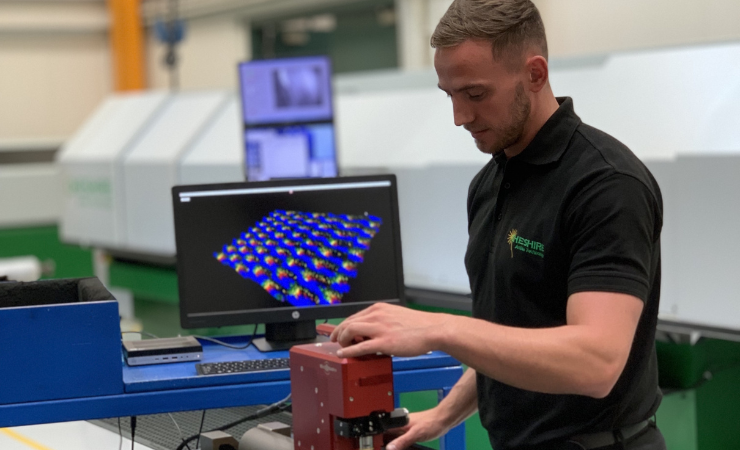

Zecher offers “specialised” inspection methods to test the scoop volume of anilox rollers

“It is imperative that when an anilox roller is returned to storage that any chips or scoring lines have been documented. The volume should be measured, and the data should be captured so the prepress department knows that roller is 100% ready to run the next job.”

Ms Arcos says that Cheshire’s engineers can conduct an anilox roller audit with clients, relatively quickly and with minimal press disruption. Other anilox manufacturers can no doubt do the same. “However, since suppliers are not typically in a printer’s facility on a daily basis, the printer should invest in measurement tools and gain knowledge in order to diagnose and address print issues themselves,” she adds.

Part of the inspection process should be the comparison of solid ink density and/or line colour transferred by the new roller to established standards, Ms Arcos continues. This comparison of roller performance to established standards also can be used throughout the life of the anilox roller by utilising running targets on live jobs. After each test, the data gathered should be logged properly in the prepress department to avoid using anilox rollers that are substandard.

Under the microscope

The trend towards collaboration between flexo printer and anilox supplier is something that Brent Zurcher, director of operations at MicroDynamics, comments upon too. The company is the developer of Veritas – one of the new breed interferometric microscopes that are enabling the industry to keep inspection capabilities somewhat abreast with the incredible sophistication of the anilox rollers themselves.

Mr Zurcher makes a comparison with a printer ordering a mandrel for their press: they measure the diameter with a micrometer and they can expect to achieve a mandrel consistent with the supplier’s certification within an incredibly tight tolerance.

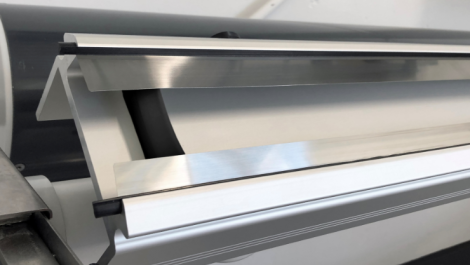

Troika Systems’ AniCAM HD Plus is said to deliver significant make-ready waste and ink savings

“Our goal is to create this same connection between printer and anilox supplier, and although there are a lot of variables involved, the first step is to use the same volume measurement technology. We educate all of our customers that our goal is to create a productive collaboration with their anilox supplier. That means utilising a process of verifying incoming volumes that both parties trust, and an open dialogue about things that can be improved on both sides.”

He emphasises that these kinds of programmes are no longer seen as a luxury in the sector; that today they are more widely accepted as a “requirement for flexographic printers that want to remain competitive in a market with increasing quality demands, and that demands high operational efficiency to be competitive”.

Even in the corrugated sector, Mr Zurcher observes, tools such as Veritas – which now has a magnetic base attachment for in-press anilox inspection – are making an impact. “Probably the last place you would expect to see an interferometric microscope is hanging off the side of a corrugated press. The idea that the volume of these rollers can be measured in-press in these manufacturing environments using an interferometric instrument is remarkable.”

Specialised methods

Another anilox roller manufacturer that involves itself closely in inspection is Zecher, claiming to offer “specialised methods” for analysing the condition of aniloxes. Two methods it highlights are VoluCheck and Soprin’s Dotscope. The first of these involves determining the actual scoop volume of the anilox by applying a defined quantity of test ink to the roller surface, followed by an application-oriented doctor blade process and creation of an imprint of the measuring area. Special software then calculates the actual scoop volume by dividing the amount of liquid by the surface area.

Dotscope analysis uses a focus variation method to determine the geometric scoop volume of the anilox, using a device placed on the roller surface, which takes up to 150 layered images of the engraving. An algorithm then creates a 3D depth model of the cell structure to calculate the volume of the cells.

To manage results efficiently, Zecher provides an app where all inspection results can be stored, allowing comparative results with previous inspections to be seen at a glance, enabling better predictive maintenance that reduces downtime.

Monitor and manage

Troika Systems’ AniCAM 3D inspection devices are also commonly used in the industry, and the company says these tools, combined with its Anilox Management System (AMS), enable printers to “monitor and manage anilox volume, wear and cleanliness with complete accuracy”.

Again, data is critical, with measurements stored in an inventory database, allowing trend analysis and tracking of the history of each individual anilox roller. Troika provides some figures on the “real-world ROI” of such devices, claiming that a narrow web printer with four presses might save one hour per press, per day, amounting to £7000 per week; a wide web printer with three presses – two-plus hours saved per press, per day, and £21,000 per week.

Adrian Buratta, sales & marketing director at Troika Systems, comments: “From ink waste to press downtime, the true cost is hidden in inefficiencies. With AniCAM HD Plus and AMS, users report 15%+ make-ready waste reduction, 55% ink savings, and dramatic increases in colour consistency and throughput.

“Inspecting your anilox isn’t a luxury; it’s a necessity. If you can’t measure it, you can’t control it – and if you can’t control it, you can’t improve it.”