The need to deliver large amounts of key information to consumers with only limited space on labels and packaging to do so has seen the rise of the multi-layer label. FlexoTech looks at what is needed to handle this application successfully.

Multi-layer labels, extended content labels (ECL), peel & reveal, peel & read – whatever moniker you use, this is one flexo (and digital) printing application that is growing fast in its importance.

The concept began, it seems, in the pharmaceutical industry, where space for carrying the product information demanded by legislation was limited. The multi-layer label became an effective way to include information such as dosage instructions, multi language content, safety warnings and regulatory text, without increasing the size of the pack.

Gary Roberts, Edale

“Today, the same principles are being applied far beyond pharmaceuticals,” says Martin Teilberg, global marketing manager for flexo press manufacturer Nilpeter. “We see strong growth in industries such as food, personal care, industrial chemicals, and agrochemicals – all driven by the need for multi-language labelling, increased traceability, and sustainability goals. Brands want to reduce the use of outer packaging, and consumers demand transparency in labelling.”

According to Gary Roberts, head of sales EMEA at another flexo press manufacturer, Edale, the growth in requirement for multi-layer labels is such that “for flexo printers, being able to handle complex multi-layer labels inline isn’t just a nice added bonus, it’s becoming a strategic necessity”.

Technical complexities

That being so, what does the production of multi-layer labels on a flexo press require of man and machine? Mr Roberts continues: “Multi-layer labels introduce a range of technical complexities; they require highly accurate and predictable registration between multiple webs, consistent web tension, and the ability to delaminate and handle challenging substrates. What’s more, high quality lamination is essential. Once you factor in embellishments such as foiling, tactile varnishes, multiple reverse prints, digital watermarks, and variable data, it’s easy to see how these applications stretch the capabilities of a conventional press.”

“Multi-layer labels introduce a range of technical complexities; they require highly accurate and predictable registration between multiple webs, consistent web tension, and the ability to delaminate and handle challenging substrates.” – Gary Roberts

He adds that for efficient multi layer label production, converters need presses that offer far more than just high-quality printing. They require the ability to combine multiple processes – printing, lamination, delamination, embellishment, die cutting and inspection – into a unified, streamlined workflow.

“Maintaining precise registration and web tension across complex constructions is essential, especially as run lengths shorten and substrate types become more varied. Equally important is flexibility. As brands’ demands continue to evolve, converters must be able to keep pace and adapt quickly without compromising on quality or efficiency. That means investing in modular platforms that support a wide range of inline capabilities and can be easily scaled or reconfigured over time.”

Gallus is another press manufacturer that has seen a steady increase in flexo printers looking to expand into this application in recent years. It says it supports multi-layer labels across its entire product portfolio, illustrating that this is becoming a more mainstream requirement for its customers.

Thomas Schweizer, head of global sales at Gallus, points to a number of technological essentials: accurate web transport and handling; flexible positioning of printing and converting units at specific stages; exact register control between layers at high speeds.

“These challenges make multi layer label production one of the more demanding inline applications for flexo converters. That’s why Gallus emphasises smart, connected printing and a modular press architecture, allowing converters to tailor configurations to each job,” said Mr Schweizer.

Thomas Schweizer, Gallus

He goes on to highlight the central importance of the flexo press HMI (Human Machine Interface), providing operators with “real-time control and monitoring over all processes”, adding: “The HMI system enables seamless operation of the full production chain – from flexo and screen printing to lamination, embellishment, and die cutting – live feedback on accuracy across each unit and lastly, quick adjustments and fault detection, reducing waste and downtime. This level of process control is essential to meet the precision required for multi layer applications.”

Set up and control

Tension control and register and pressure control are the two key technical factors highlighted by Bobst’s product marketing manager Andrea Pasquinelli, and he observes that the company’s flexo presses can be equipped with Print Tutor and Print Tutor Plus to address these issues. Print Tutor automates length and side register set up and control during production, with a mark-to-mark detection camera on every printing unit.

“The camera starts to make the correction of the second colour as soon as the first one, the master colour, arrives to the second print unit. This is the same for every print unit. So, the correction is immediate, and the job will be perfectly in register once it has completed the machine web length. In this way, you will reduce the make ready time and waste to a matter of a few seconds and metres.”

“The HMI system enables seamless operation of the full production chain, live feedback on accuracy across each unit and lastly, quick adjustments and fault detection, reducing waste and downtime.” – Thomas Schweizer

Print Tutor Plus builds on this with four servo motors on each print unit to deliver an automatic pre-set of pressure, based on the thickness of the material; a setting of the pressure from the main HMI; personalised pressure curves to manage ramp-up; and the possibility of removing pressure before job changes for easy and smart plate cleaning.

Efficient production

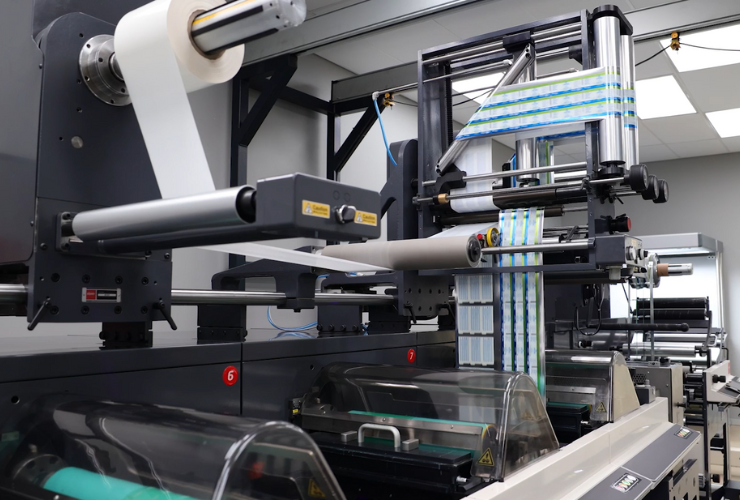

Further flexo press manufacturers discuss specific technologies they offer for the efficient production of multi layer labels. MPS Systems, for example, says its MPS Crisp. Dot technology enables the stable web transport of different supported or unsupported materials and lamination in register at high speeds. Customers can therefore produce the most complex multi layer label in a single pass, said MPS, either through the use of a cross-over unit, or by printing and laminating more than one web at the same time for higher productivity. The company added that this capability also allows for downgauging the overall material use and thicknesses of the multi-layer label.

From Mark Andy comes the “Gizmo” – more properly known as the parallel web translator, or PWT – which is a unit developed specifically for multi-layer labels. This is a compact device that can be specified on press installation or retro f itted as the need arises. Designed to allow the printing of two-layer labels on a standard printing press, it is available in up to 20-inch (508mm) web widths, is capable of handling as many print colours as the press is fitted with and operates at full press production speed. If required, says Mark Andy, two ‘Gizmos’ can be fitted to a press to allow up to four layers of labels.

The company describes a hypothetical scenario, where a label converter’s customer wants CMYK on the first label layer, and CMYK plus a spot on the second. With Gizmo, the CMYK plates are used to print both label faces simultaneously, saving ink and set up time; then the web is slit and translated on top. In addition to the Gizmo, the press can use a delam/relam unit to allow printing on the adhesive side of the label, expanding the viewable content, or printing a ‘deadened corner’ for ease of-peel. Silicone release varnish can be used to create a peel & reseal label with a permanent hinge.

Mark Andy also supplies a Constant Tension Laminator, for laminating full width, pre-printed webs in register onto a live running web.

Precise cutting, substrate and design

Three further considerations are highlighted for multi-layer production. Firstly, and continuing on the printing/ converting technology aspect, Nilpeter highlights the need for precise and accurate die-cutting, allowing for clean peeling, reapplication or opening and closing. One way to manage these demands is to integrate adjustable anvils into the die-cutting unit, which helps to control kiss-cutting depth and working with substrates of varying thicknesses.

The crossover unit for multi-layer label work, on a Nilpeter press

From Focus Label comes the importance of the choice of substrate, which it says is critical. It must be durable enough to withstand multiple peelings while maintaining its strength and integrity. Synthetic papers that are tear-resistant and extremely durable are ideal for peel and reveal applications, while vinyl and polypropylene are robust and flexible, ensuring that the labels can be peeled and resealed multiple times without damage or loss of print quality. Adhesives can be used that are specifically designed for peel and reseal applications, and these ensure the individual layers of the label remain securely in place yet are easy to peel when needed.

And lastly, the need to design the job correctly for the production demands and the functional needs of the application – for example, to ensure that consumers can read the print easily and understand how to peel the label to view the information. Artwork needs to be prepared to ensure production factors such as trapping, reverse printing and precise die-line positioning are all correct.

There is a lot to keep in mind to be successful at multi-layer labels – but a lot of experience and expertise is on hand at the press manufacturer end to help smooth the path to success.

Q&A with Hilton Janse van Rensburg, managing director at VR Print, Durban, South Africa

How much interest are you seeing from customers for this label application?

We’ve seen sustained and growing interest in multi-layer and extended content labels (ECLs), particularly from the cosmetics & personal care, pharmaceutical & nutraceutical, and food sectors. These industries increasingly require solutions that meet stringent regulatory, multilingual, and branding requirements – all within the limited space of a product label.

What are the technical challenges involved in producing them on an inline flexo press and in the converting stages?

Maintaining precise register across multiple webs and print stations is critical, as is effective tension control, especially when running varied substrates, adhesives, and laminates. The need to incorporate embellishments such as cold foiling, tactile varnishes, or security features without compromising label functionality adds another layer of complexity. Each construction – whether it’s a butterfly label, duoview, or resealable multi-page format – requires careful material and adhesive selection to ensure both performance and print quality.

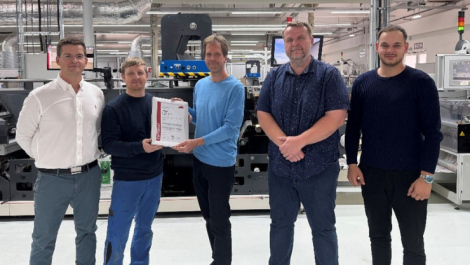

Hilton Janse van Rensburg (right), with his brothers and co-owners of VR Print, Justin and Paul

What investments have you made specifically to address these and enable multi-layer label production?

Our Nilpeter FA-Line flexo press – with eight print stations, dual LED/ arc curing, a crossover unit, quick change die station, and high-speed matrix stripping – serves as our core platform for inline production of peel & win, coupon, and peel & read labels. Variable data printing is handled offline to ensure speed and accuracy without compromising production throughput. Inspection and finishing are equally robust. All rewinders are fitted with 4K 100% inspection cameras, and we’ve added bi-directional re-inspection capabilities – critical for regulated sectors such as pharmaceuticals, where traceable correction of errors is required.

What challenges outside of production does the application present?

Many of the challenges outside of production have been addressed through our rigorous artwork control and approval workflows. All files are encrypted, securely backed up, and version-controlled – enabling accurate execution even across complex, multi language projects.

That said, variable data and serialisation can introduce additional complexity, particularly in the biocides and animal health sectors, where we’re increasingly asked to integrate unique identifiers and secure QR codes into multi-layer constructions. These jobs require more planning and coordination during prepress and client briefing stages.

Project management also plays a larger role with ECLs. Compared to standard labels, these formats demand deeper collaboration – not just with procurement, but also with regulatory teams, brand managers, and creative agencies.