Cold foiling has become a commonly used embellishment applied directly on the flexo press. Andy Knaggs looks at what goes into delivering beautiful inline cold foiled print.

It is so frequent for flexo presses to be specified from the outset today for cold foiling capability, that it would be easy to dismiss inline cold foiling in flexo as something simple, something standard. However, this does not mean that the process is necessarily free from some level of complexity – press operators still need to know what they are doing to get the best cold foil effects from a flexo press.

The cold foil printing process requires the application of UV-curable adhesive to the parts of the substrate that require foil, followed by the foil itself being pressed into the substrate in those areas. UV lamps (LED or standard UV) then cure the adhesive to create a strong bond, and excess foil left on the carrier film is removed.

While not generally considered capable of the kind of quality finish that hot foiling can deliver, this kind of cold foiling can still be an incredibly effective embellishment, bringing a new and cost-effective dimension of impact to flexo printed work. As it is applied on the press itself, it can also be undertaken in the same pass as printing and a range of other embellishment or converting processes, such as laminating, screen printing and die-cutting.

Growing demand

Press manufacturer Nilpeter says it is seeing noticeable growth in demand for inline foiling solutions, particularly cold foiling, among narrow and mid-web flexo printers, reflecting the increasing demand for high-value embellishments and differentiation in label and packaging applications. Many of the presses it sells are specified with a cold foil unit in the configuration, making it “almost standard today”.

Even if not specified at the outset, inline foiling is a straightforward retrofit option for most modern flexo presses, according to Nilpeter’s global marketing manager Martin Teilberg, who says: “The process involves integrating the foiling module into the existing press layout, with minimal disruption. Nilpeter presses are designed with flexibility in mind, allowing for seamless adaptation to incorporate cold foiling or more advanced solutions like the Pantec Rhino.”

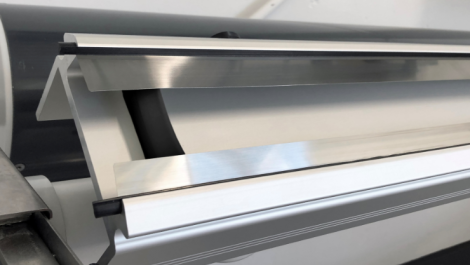

The foil and the application (picture courtesy of API Transfer Technologies)

It is very likely that any reputable flexo press manufacturer in the narrow and mid-web category would convey a very similar message. So, it is not really the press itself that makes the difference, when it comes to inline cold foiling. Although an experienced press hand might say they can do great foiling with their eyes shut, there are factors that have to be considered.

Nilpeter confirms that it offers comprehensive training programmes to its customers, and works closely with foil suppliers to ensure optimal application results.

“This collaboration helps customers gain the necessary know-how and confidence to run foiling jobs effectively and efficiently. Success in inline foiling depends on understanding the interaction between foil and substrate – specifically, material absorption and the bonding process. Selecting the right foil and adhesive for each job, and fine-tuning press settings, are critical for achieving consistent, high-quality results,” said Mr Teilberg.

Anilox role

An often overlooked factor in cold foiling in flexo is the anilox roller. It should, in fact, be at the heart of the production process, according to Stuart Mitchell, Sandon Global’s technical director for print.

“Its role in controlling the precise volume of UV adhesive applied to the printing plate is key,” says Mr Mitchell. “The success of the inline foil transfer, both in quality and efficiency, starts with this critical component and it can be an expensive decision to get wrong.

“With its direct impact on adhesive laydown, print quality, and the final appearance of the foil effect, choosing the correct anilox specification means matching volume, line count, and cell geometry – not only to the adhesive formulation, but also to the substrate type and complexity of the design. Getting this wrong results in everything from patchy foil transfer to blurred edges, material waste and inconsistent results.”

Mr Mitchell observes that for converters using filmic substrates, particularly in narrow web applications, the margin for error in adhesive application is especially slim. The adhesive coat weight determines the volume, and this is critical, he says, for precise transfer that will optimise foil adhesion and allow accurate registration at speed.

Fellow anilox manufacturer Anilox Laser Technology (ALT) points out that although cold foiling is an embellishment, the process itself is in effect a printing one, albeit of adhesive. Therefore, correct anilox specification is important. Ade Morton of ALT says elongated cells on the anilox help with giving a higher screen count, allowing tighter pixel presentation of the coating to be applied to the plate, while still achieving the desired coat weight of adhesive.

API’s foil products are suitable for plastic films, self-adhesive labels and coated and non-absorbent papers

“If the foiling is solids, then a standard line count anilox is required; if the foiling is detailed and has fine serifs etc. then a higher line count and less volume is required. We do often see the solids and fine detail are combined so we offer a hybrid specification to cover both requirements.”

Most flexo printers are keen to limit the number of anilox specifications they hold in inventory, and standardisation is consequently one of the trends in the anilox world. “Therefore, we often offer just one foiling specification, and we work with our customers and the foiling suppliers and coating suppliers to achieve the optimum spec,” says Mr Morton.

“We will arrange a foiling test plate and then do some on site trials. This gives the best results and ensures we get the specification correct for the chosen adhesive, foil and substrate. It’s largely a tailor-made approach.”

Sandon Global’s Stuart Mitchell adds: “The takeaway is simple: the anilox isn’t just a component, it’s a key enabler of print quality, process consistency, and profitability in cold foil applications.”

A perfect foil

It would be remiss to discuss cold foiling without mentioning the foils themselves. There is of course a vast range of cold foil products on the market, different grades, different shades. Printers should always consult with materials suppliers and technology partners to ensure they are able to achieve the desired foiling result.

API Transfer Technologies is one of the leading suppliers to this market, with cold transfer narrow web products designed for use on all narrow web printing presses equipped with a cold foiling module. Its products are compatible with all UV-cured inks and coatings and are suitable for plastic films, self-adhesive labels and coated and non-absorbent papers. They are also all over-printable, so that different colour foils can be achieved with silver metallic foil.

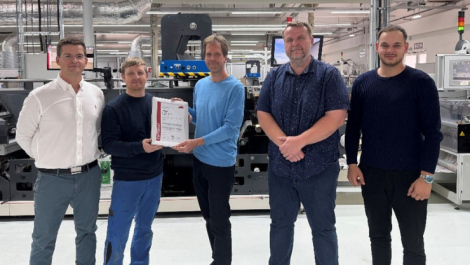

John Demoz, market support technician for API Transfer Technologies, says there is significant demand for cold foiling products, and highlights the recent equipping by API’s customer Eurostampa of a new site in Cumbernauld, Scotland, with several new Omet flexo presses, all of which, he says, have inline foiling capability.

Mr Demoz says it is good for flexo printers to get training through their press manufacturers, but that the best way to ensure success with cold foiling is to experiment with the materials and get to know which grades work well on the machine – a kind of sandbox where mistakes and learning can happen.

“The main thing is to get to know the grades, because that can make or break what you are doing,” he said. “Do trials, ask questions; don’t assume things will work. Working closely with us can make a huge difference to any downtime and perceived quality issues.”