In the evolving landscape of flexography, printing sleeves have established themselves as a reliable printing form for packaging printers seeking speed and consistency. While photopolymer plates remain widely used, flexo sleeves offer distinct advantages in specific production contexts.

What Are Elastomer Sleeves?

Elastomer sleeves are cylindrical image carriers made from synthetic rubber compounds. Unlike flat plates, they are engraved all around, enabling 360° continuous printing without seams or registration issues. This format is ideal for high-speed flexographic presses where precision and repeatability are critical.

Key benefits include:

- Seamless print quality with no joints.

- High tolerance for fine detail and consistent ink transfer.

- Compatibility with water-based, solvent, and UV inks.

- Reusability through reconditioning and re-engraving.

These features make elastomer sleeves a strategic choice for printers aiming to reduce downtime, improve print consistency, and enhance overall production efficiency.

Key Applications in Flexographic Printing

Continuous flexographic printing sleeves are ideal for high volume printing across diverse industries:

- Flexible packaging: films, laminates

- Heat-shrink sleeves: bottles, hygiene products

- Bags and pouches: kraft paper, luxury plastics

- Hygiene paper: napkins, paper towels

- Medical packaging: sterile wraps, tablet sealing

- Ruled and specialty paper: notebooks, pads

The ability to recondition flexo sleeves—by removing the outer rubber layer, applying a fresh one, and engraving a new artwork—adds to their appeal in sectors where sustainability and cost-efficiency are priorities.

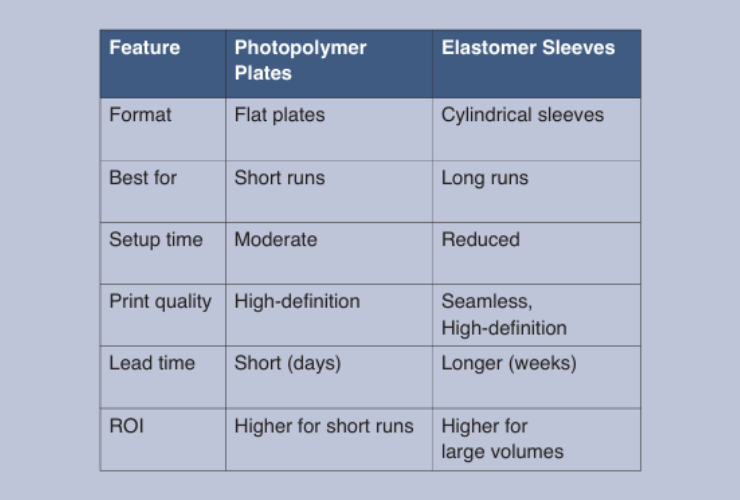

Elastomer Sleeves vs. Photopolymer Plates

How to Choose the Right Printing Sleeve Supplier

Selecting a supplier for continuous sleeves involves evaluating several key criteria:

Technical Expertise

Look for mastery across the full sleeve production cycle– from base material selection, rubber covering to laser engraving. Prefer suppliers equipped with advanced laser engraving systems for enhanced precision and customisation.

Application Versatility

Ensure support for various substrates, ink systems, and press configurations. A wide range of printing sleeve dimensions is essential.

Sustainability Practices

If possible, prioritise suppliers that offer rubber sleeve reconditioning to contribute to waste reduction and cost savings.

Customisation & Support

A personalized approach to sleeve production—adapting to specific press settings, anilox rollers, and ink systems—can significantly enhance print quality. Technical support and consultancy services add value beyond the product itself.

Certifications

ISO certifications provide assurance of consistent quality and responsible business practices.

Supplier Spotlight: Miller Graphics

Located in Limoges, France, Miller Graphics’ printing sleeves production hub is equipped with the latest technology and staffed by a team of multilingual technical experts committed to meeting the unique needs of each printer. By investing in innovation, including the recent acquisition of a new laser engraving unit, the PremiumSetter D2000 Hybride from Hell, Miller Graphics’ printing sleeves meet the highest standards of performance and durability.

For printers seeking a one-stop-partner, Miller Graphics offers a compelling value proposition:

- Full Production Chain: Miller Graphics manages everything from fibreglass sleeve production to rubber covering and laser engraving. A vertical integration allows for greater quality control and responsiveness to customer needs.

- High Capacity & Global Reach: Producing nearly 5,000 sleeves annually in over 160 dimensions, serving 180+ customers across five continents.

- Sustainability Through Reconditioning: Used sleeves can be relined and re-engraved, extending their lifespan and reducing environmental impact. This capability supports both ecological goals and cost-efficiency.

- Tailored Technical Support: Miller Graphics offers project specific base material analysis, prepress guidance, and customization. Technical teams adapt sleeve specifications to match customer equipment, ensuring optimal performance across various substrates and press types.

- Certified Excellence: Miller Graphics Limoges is ISO certified and EcoVadis Silver-rated. Miller Graphics Group operates 14 sites with a €43 million turnover and 365 employees.

Visit www.millergraphics.com to explore the full offering

This article is an advertorial; the featured company created the wording and paid for its placement. It has been checked by Whitmar Publications to ensure that it meets our editorial standards.