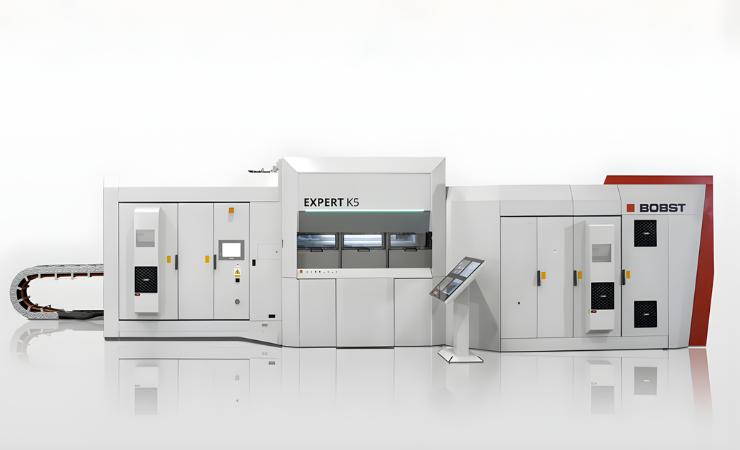

Bobst has launched the next generation of its Expert K5 metallizer, an automated solution for high-quality film production that incorporates artificial intelligence (AI) to enhance consistency, efficiency, and sustainability.

The new system uses Bobst’s Intelligent Metallizing Assistant (iMA) technology to simplify vacuum metallizing operations. It automates processes that were previously manual, including temperature control and setup, allowing faster changeovers and more repeatable results. The equipment also reduces power and consumable use, contributing to lower operating costs and environmental impact.

“The metallizing industry struggles to find skilled staff,” said Richard Sandbrook, product line director of vacuum metallizing. “These are complicated processes, and it takes a long time to train new operators – then retention can be difficult. Operator turnover and limited expertise cause quality issues and higher waste, especially when running new challenging materials or complex processes. With the next generation Expert K5, Bobst is advancing this powerful technology by increasing automation for even better productivity and consistent quality.”

The Expert K5 integrates AI-driven process monitoring through a full-width control system that replaces manual inspection with high-definition cameras and automated temperature management. A new operator console consolidates all functions in one interface, while connectivity via Bobst Connect enables remote viewing, support, and diagnostics.

The system can process a range of substrates including BOPE, MDO PE, CPP, paper, and low-temperature BOPP films across widths from 1350 to 4850mm. It also supports thinner films and incorporates Bobst’s AluBond process for metal adhesion and barrier performance, with an option for AlOx GEN II transparent film production.

Davide Garavaglia, general manager and head of product lines gravure, vacuum, coating and laminating, said: “The Expert K5 is the perfect example of how Bobst’s vision – based on automation, digitalisation, sustainability and connectivity – can transform the packaging industry. With this innovation, converters can achieve new levels of quality and productivity with less waste and complexity.”

He added: “This is the first metallizer on the market to feature such advanced automation, operating largely autonomously without the need for skilled operators. No other solution offers this level of intelligence and independence. As such, the launch is a true turning point for the flexible packaging sector – decoupling human expertise from product quality by ensuring exceptional, repeatable coating performance and yield.”