Press manufacturer Allstein is claiming a world-first took place at its Herford headquarters in Germany this week, as an audience of packaging print professionals witnessed a live demonstration of the “first fully automated flexographic workflow shown in public”.

The demo set a “new benchmark in efficiency, workflow standardisation and roto-gravure-level quality”, the company said, bringing together technologies from Allstein, Esko, Kongsberg PCS, and Asahi Photoproducts, to deliver a “seamless” end-to-end flexo production run. Describing it as a game-changing step forward, Allstein added that “Flexo 5.0 is already a reality”.

Attendees to the event saw how all partners had integrated their systems to build a seamless, intelligent, and sustainable flexo line. Every step of the print packaging production workflow, from plate imaging, exposure and processing to cutting, mounting, and printing, was automated.

According to Allstein, attendees praised the line’s clarity, precision, and speed. A photograph taken at the beginning of the event was automatically processed during the demonstration, and visitors were given a freshly printed copy produced on the flexographic press.

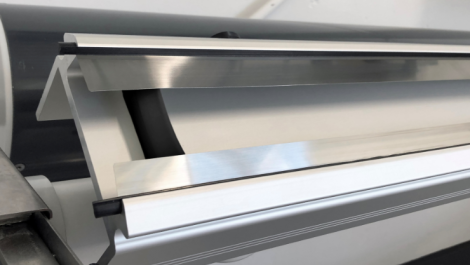

The demonstration included Esko’s CDI Quartz plate imager and XPS exposure systems, Asahi’s CrystalCleanConnect automated plate processor, Kongsberg PCS cutting table, and Allstein’s automatic mounting system and its Genesis flexo press, including sleeve and anilox chamber handling. The integration reduced operator requirements to one, bringing “unprecedented automation and standardisation to the workflow”. The result, the company said, was reduced manual intervention and a “significant leap forward” in industrial productivity.

The partners put the technology demonstration in the context of the ongoing shortage of skilled labour in the sector, reflecting a broader industry trend: leveraging automation to reduce repetitive tasks and deploy human expertise to higher-value tasks. Allstein pointed out that gravure printing is already widely used and highly automated in Asia, and said that flexo is now catching up through end-to-end automation.