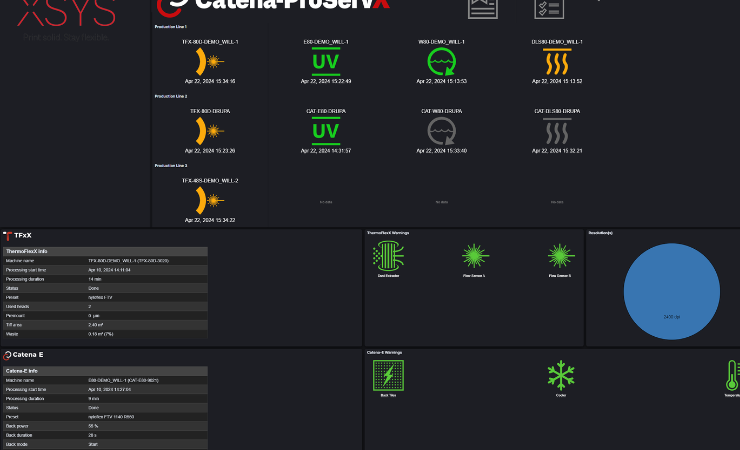

Flexo prepress solution manufacturer XSYS has introduced Catena ProServX, a cloud-based, real-time equipment monitoring tool for proactive maintenance and superior quality control for use with its Catena plate processing and ThermoFlexX TFxX Imaging equipment.

By precisely measuring equipment performance, energy consumption, and consumable usage, ProServX provides customers with insights into their operations. With this data, decision-makers can make informed, data-driven choices to optimise overall equipment effectiveness (OEE) and ensure the highest quality standards, while minimising waste for sustainable plate making.

‘Catena ProServX represents a significant leap forward in digitalising equipment management and key performance indicators (KPI) reporting. It is a connected, cloud-based solution that delivers immediate data about asset performance and consumable usage according to industry 4.0 principles,’ said product manager of PrePress Equipment & Software at XSYS Bert Eeckhout.

‘This new software development provides a unique access to plate processing data which until today was not available. Now, with the launch of ProServX customers can access and use this data to optimise their operations and make fact-based decisions.’

ProServX provides in-depth production reports at regular intervals detailing the number of plates produced during the specified period, along with the materials consumed. Alerts are sent out if any abnormal activity is registered, such as excessive solvent usage or a malfunctioning lamp, enabling customers to engage in proactive error management and predictive maintenance actions.

XSYS described the ProServX’s ability to generate individual reports for each job with detailed insights from laser exposure to plate finishing as a standout feature. With this level of traceability, platemakers can ensure 100% quality control, promptly identify and resolve issues, and optimise resource allocation for enhanced efficiency and productivity, according to XSYS. The data provided by ProServX accelerates remote service capabilities, reducing unnecessary travel for technicians.

Mr Eeckhout concluded, ‘Catena ProServX represents a holistic approach to remote equipment management by offering advanced statistics, comprehensive reporting, and unparalleled support. It is not just a software solution but a real catalyst for improving production performance and achieving sustainable business success in today’s dynamic landscape.’