South African flexo label printer Redfern Labels has welcomed a new MPS EF 340 ‘next generation’ flexo press to its production facility in Johannesburg. The system is a 9-colour 350mm flexo press that includes MPSConnect, delam/relam and turnbar, multilam (coldfoil) and a separate laminating unit, two die stations with Wink’s SmartGap adjustable anvil systems, and Phoseon’s Nexus one UV LED curing systems.

The MPSConnect feature provides real-time performance insights of the MPS EF press through the collection of multi-directional data from hundreds of sensors every second. This data collection helps identify bottlenecks, errors, and inefficiencies in the operator process, optimise press performance, and decrease waste.

With office and manufacturing facilities in Johannesburg and Cape Town, and a satellite office in Durban, Redfern Labels is a producer of flexographic labels including pressure sensitive labels, printed BOPP and shrink sleeves. For over 30 years, Redfern has been a key labelling partner to farmers, fruit exporters, educators, entrepreneurs, and household brands.

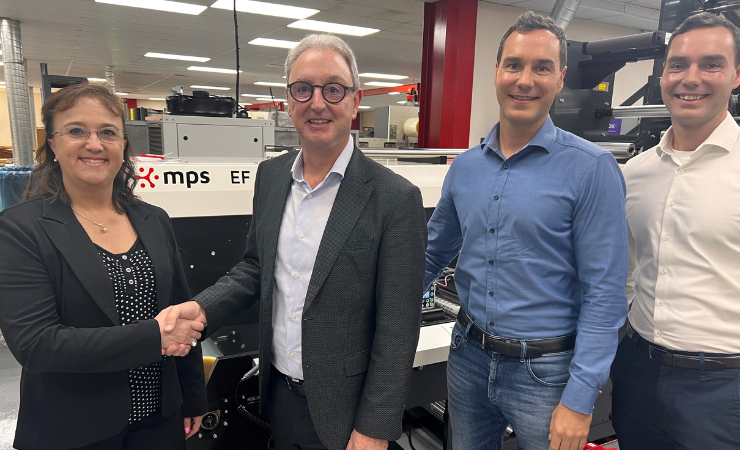

The machine sale was led by Patrick Aengenvoort, Rotocon director and co-owner, and Marius van Lith, MPS regional sales director. The installation was completed by a team of MPS and Rotocon service technicians.

‘We thank both MPS and Rotocon team members involved with the realisation of our beautiful MPS printing machine we have affectionally named Marvel, for their excellent workmanship, patient nature, and passion for what they do,’ commented Terry Adinolfi, managing director of Redfern Labels.