Lohmann has launched an adhesive tape for the flexographic printing industry to increase press uptime while maintaining ease of demounting.

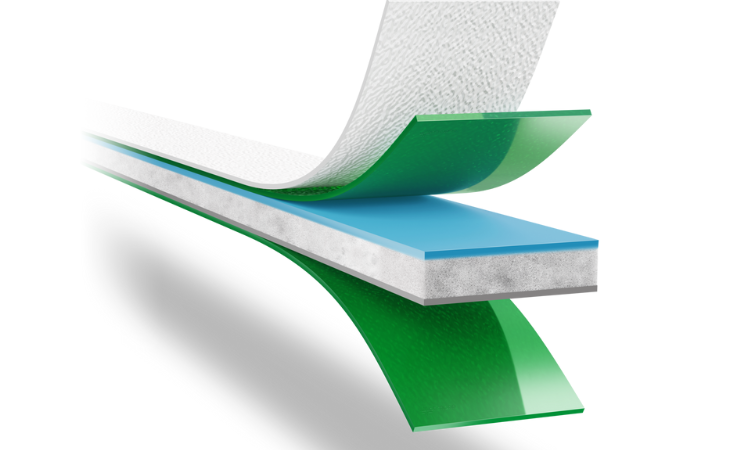

Duploflex Grip uses 50 percent less solvent during the coating process and combines the viscoelastic properties of a polymer foam with a specially developed, solvent-free pure acrylic adhesive. The composite structure prevents edge lifting and plate damage during demounting.

At the same time, a plate mounting tape must meet the increased demand for sustainable products and processes. No edgelifting in the running process, machine downtime due to makeready and generally high material consumption are key factors considered in the formulation of Grip tapes. With leading equipment manufacturers, Duploflex 5 GRIP has been measured to have significantly higher reusability for the first time.

Peter Nissing, head of market management graphics at Lohmann, said, ‘The solvent-free adhesive and 100 percent recyclable packaging are part of our corporate strategy for sustainability. The increased reusability of the adhesive tape is an important argument in the discussion about resource conservation and responsible use of raw materials. The improved Grip adhesive package is also characterised by its low sensitivity to temperature and humidity fluctuations.’