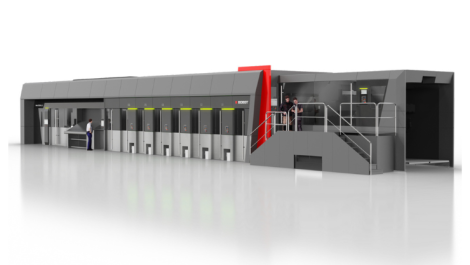

West Lothian-based Glenhaze has ordered a Bobst VISIONCUT 1.6 die-cutter with solid board feeder, the first of its kind in Scotland, to support contingency planning for customers and increase capacity.

The investment comes as the company seeks to adapt to the growing need for robust transit packaging solutions, driven by the huge consumer shift to online shopping during the Covid-19 pandemic.

Gary McCulloch, managing director, at Glenhaze said, ‘We are fully committed to being at the forefront of packaging development and manufacturing within the markets we serve. For us, manufacturing and innovation are intrinsically linked; we put innovation at the heart of everything we do and work closely with customers to identify their needs and create a bespoke solution. As such, we are keen to invest in our facility and stand-out technologies that deliver continuous improvement for us as a business and, most importantly, our customers.

‘The VISIONCUT 1.6 with solid board feeder is a distinctive set-up that will enable us to handle more intricate, complex jobs that are particularly demanded by the premium spirits market. Once installed, it will complement our existing Bobst SPO VISION die-cutter and bring greater flexibility to our operations, enabling us to run the same job across two machines when required, or simply speed up job changeover. Ultimately, it will allow us to be more customer-led, responding to clients’ evolving needs rather than what suits the processes.’

The VISIONCUT 1.6 is able to handle a wide variety of substrates and comes with built-in machine performance analysis to monitor uptime and productivity in real-time, enhancing sustainability and efficiency along the complete production line.