A survey conducted by FTA Europe shows that those in the printed packaging value chain had consistent or increased demand at the height of the Corona crisis.

However, the same survey showed that those reliant on the custom of closed businesses struggled. Another key issue was ensuring continued supply of essential components, particularly due to the heightened pressure from consumers as well as due to border closures. For printers, obtaining synthetic ethyl alcohol was difficult because of the increased production of disinfectant at the height of the crisis. FTA Europe and its members worked hard with the authorities to resume regular supplies.

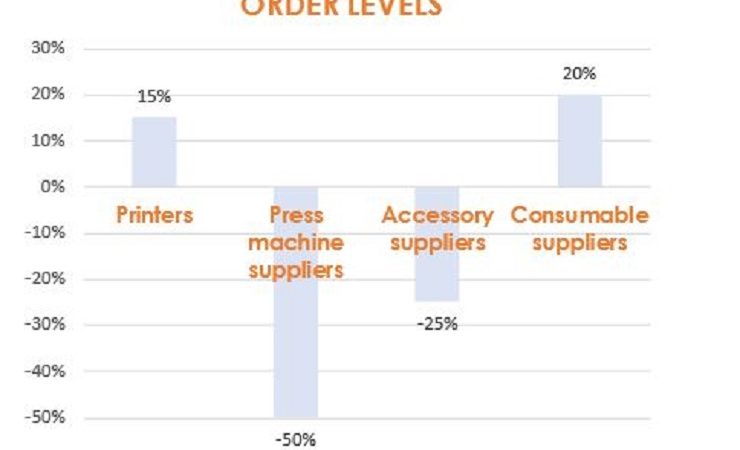

Although in general the demand for new machines decreased, some packaging printers bought new presses to meet the extra demand. Other machine suppliers said that focus was on maintaining customer contacts to finalise a sale post-lockdown. Installing machines took place virtually. Communication was widely seen as a challenge, particularly when technical conversations between printer and supplier were required. However, digital communication has become normalised, and many survey respondents said this is set to continue for certain tasks, as it is seen as a time and cost saving measure.

One the major trends identified by the survey was the ‘toilet paper effect’ which led to a spike in demand of certain products during the crisis, but this will regulate over time (usage has not increased)

There is also some hope that the industry could see the end of plastic bashing. Some association embers reported that hygiene concerns and the need for food longevity changed people’s perception of plastic. But others said there will be no long-term impact on the (negative) way the wider public view this substrate.