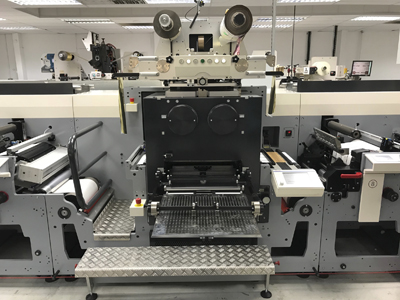

MPS and ABG combo press for The Label Makers

In an effort to reduce tooling and hot foiling cost while increasing production speed in conventional printing, The Label Makers has installed a bespoke solution featuring an MPS EF 10-colour flexo press with an integrated Big Foot hot foil/embossing module from A B Graphic International.

The company currently uses three MPS flexo presses, including an EC model running full production for over 13 years. In addition to flexo, rotary screen printing is also a feature on two of these presses. For finishing of digitally produced labels, the company owns four Digicon Series 3 digital finishing machines, with two equipped with the ABG Big Foot 50-tonne capacity hot foil/embossing module.

As the Big Foot was previously designed to accommodate maximum material width of 320mm, the combo solution involved engineering effort from ABG to accommodate a 430mm length on the MPS press.

Nick Tyrer, sales director, MPS Systems, and Tony Bell, sales director, ABG, closely collaborated during the project to ensure a seamless installation. The combination press marks the first time an ABG Big Foot module has been integrated on a flexo press, along with another first in the module accommodating 430mm material.

‘I am extremely pleased with both MPS and ABG in successfully delivering us a highly customised solution for label embellishment,’ said managing director, David Webster. ‘Within a week we were up and running – in perfect registration.’

With its MPS/ABG combo press, the company can run larger label print runs in a single pass, embellished with silkscreen or multi-coloured hot foil for luxury decoration of beer, wine, spirits and personal care labels.