Held at the company’s headquarters in Didam, The Netherlands, MPS has described its latest open house as ‘a success’. The event saw live demonstrations of the EXL410 UV full servo 14 colour offset press and an EF410 UV full servo eight colour flexo press.

Four demonstrations of the presses were held each day followed by one to one meetings to further discuss the technology and benefits. The open house also provided an opportunity for visitors to meet the sales and management team and learn more about MPS machinery.

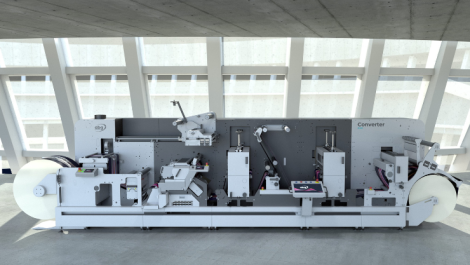

Demonstrations on the EXL410 UV full servo 14 colour offset press.

The EXL offset press, initially launched at Labelexpo Europe 2011, has variable sleeves for different repeat lengths, for both plates and blankets. The offset press can be equipped with various flexo, gravure and screen units, in addition to flexo units on rail. Multiple converting units such as hot/cold foil, delam/relam, die cutting and laminating can also be installed. A gravure unit enables users to dry solvent based inks with the use of hot air.

Another feature that press offers as an option is the Ultraflex rail system. This positioning and parking system for rail mounted units provides the ability to set aside or move the unit to the job location where it is required.

Die cutting was also demonstrated with the Change Die station which enables die cutting of fine materials and difficult shapes at high speeds, followed by a matrix removal system also engineered by MPS that shreds and removes the matrix. At full speed the offset press can run up to 200 metres a minute.

Live demonstrations on the flagship EF410 UV press included a quick material and design change. It comes with Nonstop Print Change (NPC) technology as standard, that allows the operator to prepare any idle print unit for a new design without needing to stop the press.

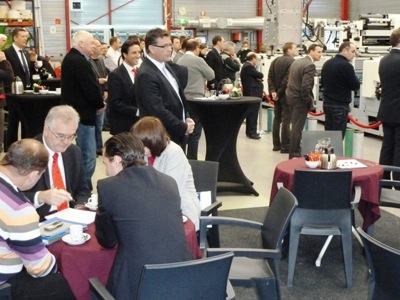

MPS managing director Eric Hoendervangers commented, ‘We were pleased with the quantity and quality of the visitors who attended the open house. The event allowed us to demonstrate our innovative technology on fully built presses, and provide guided tours of our facility. Feedback from our visitors was very positive. It is always nice to observe that every time we show the capabilities of our presses, people are amazed by the performance and wide range of design possibilities.’

The factory hall during the open house.