Perfect Proofer from GSE Dispensing

Proofing the ink is a separate function and there is a plethora of excellent hand proofing devices on the market. By Neel Madsen.

Colour matching is one of the many issues facing printers and it is a major cause of press downtime and a leading cause of waste. Hence taking time to check the ink off press offers significant cost savings as well as environmental benefits.

A hand held proofer is essentially a miniature version of the full size flexo press and can save costly testing on press thereby freeing up press time. It can also save on consumables and test the substrate.

Flexibility

Available in two versions, the FlexiProof 100 for users and producers of water-based and other ink systems, and the FlexiProof UV, a dedicated device for testing and monitoring the performance of UV flexo inks, have been designed and developed by colour communications and print/coat technology specialist RK Printcoat Instruments to resolve productivity and commercial issues in the print and converting environment, and elsewhere.

The FlexiProof is functionally identical in every way to a full sized production flexo press, yet occupies a bench top space of just 55 x 45 cm. Whether sited in a laboratory, in a dedicated pre-press environment, next to a press or elsewhere, it saves on press waste by enabling functions such as colour matching, pilot runs and research and development to be undertaken off press.

PLC controlled and equipped with quick-change ceramic or steel anilox and swing in doctor blade, the proofer offers multi-tasking capability. Operating at speeds of up to 100 m/min, it can be used with any flexible substrate. To operate the user selects and fits the appropriate anilox roller, then fixes the substrate (half A4) to the impression roller using the built in pressure sensitive strip. Printing speed is then set and ink applied using a disposable pipette. Side dams fitted at each end of the doctor blade provide a reservoir holding sufficient ink for producing multi proofs when required.

RK’s colour communication devices are available for most print processes. The K Printing Proofer can be used to obtain high quality proofs using gravure, gravure-offset or flexo inks. In addition to producing gravure, gravure-offset and flexo proofs using interchangeable print heads, both wet and dry laminated samples can be produced on the machine. Furthermore, two or more inks may be printed simultaneously for comparison purposes.

Miniature press

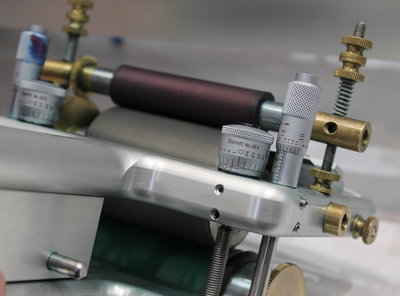

The Perfect Proofer from Netherlands-based Print Proof Solutions, developed by Integrity Engineering in the US, is an ink proofing system used to mimic flexo presses. This air driven device systematically controls speed and pressure, until it matches a particular press. Once that speed and pressure is identified, those settings become the press ‘signature’.

The system provides precise flexo colour predictability by letting ink lab technicians pre-flight their formulations under actual press conditions without the need for fingerprinting. It is essentially a miniature printing head, with a 1 or 2 inch anilox roller, and impression roller, both gear-driven to handle any paper or film substrate, including unsupported types.

Several of the proofer’s key features are identical to these of the target press, including photopolymer plate, tape materials, anilox type and cell count, drying system and substrate used. Impression pressure and nip distances are adjustable by increments of microns. As a result, the proofer is capable of offering full predictability of the target result, to within a fraction of ΔE, at the desired dot gain, avoiding costly adjustments on press.

Quick draw

HarperScientific, the printing and coatings supplies division of Harper Corporation of America, offers label converters the Phantom family of hand ink proofers for colour matching. The Phantom is a precision ink delivery device that incorporates a laser engraved ceramic anilox roller, doctor blade metering and a rubber transfer roller. This combination lays down a specific amount of ink onto the substrate producing a proof that can be used for density or ∆E measurements.

The latest addition to the company’s range of laser engraved ceramic bladed ink proofers, the Phantom QD family of Quick Draw (QD) proofers are available for flexo and direct gravure, with complete portability and manual utility-free travel operation with constant loading pressure over the length of the able. Mechanised Phantom QD table units feature an electric version utilising a universal power supply and variable speed and a pneumatic powered option. Harper is offering the motorized option on its long table Phantom QD that produces a 20 inch proof. Adding a motor to drive the proofer over the table length has eliminated another process variable.

Testing

IGT Testing Systems is active in the field of printability testing and has developed a range of testers which are used in the paper industry, the ink industry and in printing houses.

Its F1 printability tester consists of a inking section with engraved anilox roller and doctor blade, and a printing section with printing plate and an impression cylinder. The substrate is attached to a carrier and placed on the substrate guide, between the plate and the impression cylinder.

The system produces colour strips which, as well as being used for testing printability, are suitable for measuring or matching colour, visual appraisal, density measurements, including establishing colour and density tolerances and determination of coverage, wear resistance, scratch resistance, flexibility, adhesion and gloss, ink transfer, light fastness and resistance to chemicals.

The F1 will eliminate the need for colour matching tests on the printing press and prints both coated and uncoated materials, including paper, board, plastic film, cellophane, laminate, labels and textiles.