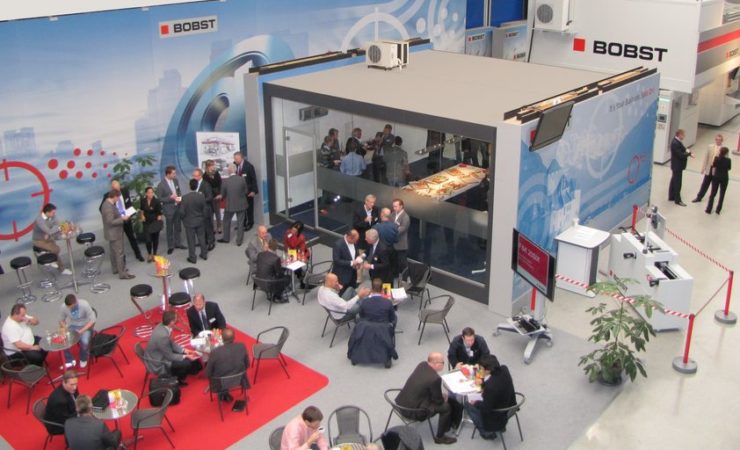

Bobst Bielefeld hosted an open house event in early October where its new smartSET impression and registration system was presented.

Reducing variables in the printing process and automating as many aspects as possible are some of the main weapons against press downtime and loss of productivity. Neel Madsen looks at how manufacturers tackle this challenge.

The human factor is possibly the biggest variable in the flexo printing process and to ensure a consistent result, press manufacturers offer many types of automation, some are built into the machinery while others can be added as extra options. Lead times continue to shrink and downtime must be kept to an absolute minimum to avoid loss of productivity while getting the press to colour and in registration need to be achieved as quickly as possible to save on substrate and inks.

Wide web presses

The need to automate the printing process on wide web presses has historically been driven by the sheer scale of the machines, and today registration and impression control come as standard on most machines.

As an alternative to its well-established offline system for registration and impression setting, smartGPS, Bobst Bielefeld (the rebranded Fischer & Krecke production site) recently launched smartSET. This is a new non-optical, semi-automatic ‘on board’ system that promises significant reductions in waste and set up time. Unlike optical systems, smartSET works with all substrates including reflective ones and eliminates plate damage caused by impression during the impression setting process.

First introduced in 2009, the smartGPS system works offline at the plate mounting stage. The company said that savings derived from eliminating wasted time and material increases profits on all jobs and give printers a decisive advantage in their ability to accept and run short jobs profitably.

With smartGPS the shorter the print runs and the more changeovers, the greater the cost savings. And, the more expensive the substrate, the greater the cost savings achieved by reduction of waste.These advantages can also be achieved on existing Fischer & Krecke flexo equipment.

With the smartCOL colour matching system, Bobst is currently developing the missing link to achieve a 100% offline registration, impression and colour set up. First seen at drupa, the system checks the ink prior to introduction into the machine, prompts necessary changes and makes sure the ink is press ready.

In addition to the ‘smart’ solutions, the company introduced a new on-press solution for impression and registration showcased at its recent Open House event in Bielefeld. Touch2Go is an optical on-press solution that reduces waste during the set up process.

Offered as standard on its EvoXD and EvoXG press formats, Flexotecnica has developed the ARF (Automated Register Flexotecnica) and AIF (Automated Impression Flexotecnica) systems as well as FlexColor Matching, featuring on-press spectrophotometry.

The new AIF system enables automatic control of print impression positions with or without the use of dedicated marks. It combines with the also newly launched ARF for automated registration and both systems are controlled via an operator touchscreen interface.

Tim Hilton, sales manager, Cerutti Graphic Systems, UK, said, ‘Following the trend of shorter and shorter run lengths set up times and set up waste reductions have become important to remain profitable. On press print and anilox sleeve changes drastically reduced changeover times, but the most recent developments entering the marketplace have focused on set up waste reduction through automated impression, automated register setting and automated colour control. Flexotecnica is at the forefront of this technology.’

Windmöller & Hölscherintroduced its automation solutions Easy-Set, Easy-Reg and Easy-Sync in 2004 with Easy-Col following on four years later. It made the companya pioneer in computer-aided colour matching on CI flexo presses, in conjunction with the added functions of ink consumption forecast and minimisation of left over inks. This year at drupa, it introduced the latest generation of Easy automation modules.

Easy-Set HD was developed to meet the higher demands from current developments in printing plate technology using high resolution. Taking into account any influencing factors, including plates, tapes, anilox rollers, substrate, etc, a line camera based HD analysis of the printed image will provide an exact proof. The system is also capable of developing a high resolution 3D graphic of the print design topography from the data gained, enabling the printer to foresee – already during the proofing phase – the specific processing conditions to be expected for the job. Print design details calling for close monitoring during production can be selected and highlighted.

New Easy-Check C provides an option to constantly check and verify the quality while printing. Quality parameters such as colour location, solids density and dot gain are automatically monitored and represented in a trend graph. Any deviations from the set point or target value can instantly be corrected. In conjunction with Easy-Col such corrections are done without interrupting production.

Comexi Group said that it has focused its R&D on developing different modules for the different needs of its customers under the Cingular brand. At drupa, the new Cingular Real solution for automatic impression and registration was introduced. This uses 100% print inspection and compares the print with a master digital file using real time image processing algorithms and then makes any adjustments needed.

The company explained that it has based its developments on the belief that the key point in selecting a system to help reduce waste during set up is the reliability of the adjustment, ie how close the automatic adjustment is to the adjustment carried out by a skilled operator manually on press. Its focus is firmly on on-press automation as it has found that ‘printing is the only way to see the real impact of all parameters’.

A year after the official presentation of its Kiss & Go automatic impression setting system, Uteco reports that it has sold 33 systems. It was initially developed for the Onyx press, but is now available on the whole product line including the Topaz, Diamond and the latest Crystal models. Extensive testing with different production materials has proven full compatible with any type of substrate and plate material.

The system functionality consists of two distinct phases. Touch&Go establishes the first and lightest contact point between plate/anilox and plate/CI. The procedure, once selected, initiates automatically once the press is started and proceeds to advance the printing decks until the appropriate contact torque is measured taking into consideration the possible variables of sleeves, carriers and plates, as well as multiple mechanical and temperature compensations. The system in essence performs the lightest mechanical ‘touch’ impression, which will serve as the base reference and starting point for Kiss&Go.

Kiss&Go performs an optical scan of the entire printed web and automatically sets the optimal printing impression. The system performs an actual reading of the printed surface and then uses an algorithm to establish the correct settings. The optical scanner is a contrast sensor, which registers the quantity of ink laid down on the substrate independently of the printed image. The system consists of a compact scanning unit located after the last printing unit, and a main processing unit. The latter analyses the data received, then calculates and performs the optimal settings by transferring these to the positioning systems of the plate and anilox cylinders.

The latest print setting system from Soma Engineering was introduced at drupa. Falcon III enables faster job setting without print marks and builds on the already established Falcon II which is available on all the company’s wide web presses along with Q-Shield for constant drum temperature control. Also unveiled at drupa was Ink Fix colour matching for reduced waste and increased efficiency of on-press colour correction.

Narrow web presses

Manufacturers of narrow web presses are approaching the challenge of reducing downtime and keeping the presses running at the highest possible speed in a number of different ways. The modular nature of inline converting offers many opportunities to improve on productivity as more processes are incorporated onto the press

Mark Andy has identified die-cutting as a bottleneck in inline converting and at Labelexpo Americas 2012, it introduced Quick Change Die-Cutting (QCDC)

to specifically address the issues of cumbersome changeovers, the speed versus quality trade-off and errors. The aim is also to make the station as user-friendly as possible.

A completely new die station was created where dies are side-mounted into the machine using a portable cart. This ergonomic design speeds up the changeovers and eliminates the need for cranes or hoists to lower the die into place.

The rigidity of the new die station design further ensures consistent die-cutting and larger diameter anvil and support rollers with robust journals allow for higher cutting pressures without movement. The distance between the die-cut area and matrix stripping point is very short, eliminating the potential for adhesive to fill the cut area on the label. High precision capstan and waste matrix spindles allow for precise adjustments in tension. This provides a benefit over older pneumatic clutches, in that operators can set a specific tension and return to that setting later, without the need for readjusting again.

The company estimates that the reduction in set up time and the increased matrix stripping speed will account for a 19% increase in capacity overall.

MPS said that it believes today’s market place has an intrinsic need for automation in order to drive down the cost price per 1000 labels, especially for short runs. It has therefore introduced Automatic Process Control (APC), which consists of three modules.

The APC-plate mounting module works on both press and pre-press automation. With amounting tolerance of max ± 0.03 mm, the plate mounter uses an optical measurement system to determine the exact position of the printing plate on the positioning table. It then mounts the printing plate precisely and fully automatically on the printing cylinder.

APC-print settings enable automated servo control of the relevant press settings. These include print sleeve and gap control (material thickness) both using double positioning servo technology. Press settings can be loaded automatically for both new jobs via the calibration database and for repeat jobs where the settings are already stored in the job memory. APC also enables pressroom managers to calibrate the press themselves.

The company has also introduced APC for die-cutting. High precision positioning servo technology applies the perfect die-cutting pressure for each die-cutting design and for each self adhesive material. MPS further offers iMatrix, a new tension controlled stripping system, which allows the press to die-cut and strip matrix at very high press speeds of up to 600 ft/min.

To bring automation into job changes, Nilpeter has introduced Cleaninking. This one component, replacing the ductor roller, ink tray and doctor blade holder, has considerably reduced the time spent on mechanical changes. Combined with electronic settings of anilox rollers, print pressure, substrate thickness and the register, it has helped optimise job changeovers. The company has also introduced the Quick-Change die, digital die technology, and the fully automatic waste rewind, the AutoMatrix.

Global sales manager, Jesper Jørgensen, explained, ‘Automation, with its efficiency and productivity benefits, is what will keep flexo technology competitive in the future – even on the market for short runs. Five years ago, the breakeven point between flexo and digital was around 2000 metres. Now with flexo automation improvements, it has been reduced to 800 metres – as a maximum.’

Nuova Gidue’s approach to automation is to utilise the advantages of digital technologies in the flexo printing process in a project entitled ‘Digital Flexo’. As both the pre-press and quality control phases of the process are already fully digitalised, the company turned its attention to the press itself.

In Digital Flexo, each printing station is fitted with an HD digital camera (the Print Tutor system), which constantly analyses and manages the print pressure, colour density and register, automatically servo-adjusting them, in order to achieve accurate printing. All print quality parameters are preserved at any speed and at each print revolution. If parameters change (substrate thickness differences, wear of plates etc), the press automatically self-adjusts to the change, reproducing the target PDF parameters.

Managing director, Federico d’Annunzio, said, ‘With the introduction of Digital Flexo, the machine ensures higher printing quality and significant waste reduction (less than 20 meters for the eight colour set up). Because everything is digitalised, the press operator can better focus on achieving the best outcomes during operational production phases.’

When Gallus developed the new EM 430 S press, it introduced a new control platform along with numerous machine innovations. The press is based on the same platform as the ECS 340 and the company is now making systematic use of the resultant synergies between the two machine systems.

The main changes on the new press include using cutting-edge technologies, standardising individual subassemblies, simplifying operation and introducing multi-platform printing accessories. For example, the RCS 430’s printing cylinder sleeves can now be used on the EM 430 S, as can the latest generation of water-cooled UV dryers for ink drying. Their lower air consumption means there is no unwanted eddying of air in the pressroom.

The most significant change is the new control system that was used for the first time on the Gallus ECS 340. The Gallus EM 430 S now benefits from a central, water-cooled control cabinet containing all intelligent control components. All that remains at the individual printing stations are small, decentralised control cabinets with the components required at each specific station.

Edale’s new FL-3 press is promoted under the tag line ‘Innovate nor complicate’. Managing director James Boughton, commented, ‘Why does an innovative product have to be complicated? Many press manufacturers are over complicating their machines, which really just means a higher cost to purchase. Edale has always produced machinery you can rely on and the FL-3 press is no different.’

The company further explained that the FL-3 is exceptionally quick to set up whilst generating absolute minimal waste. The impression pre-setting system allows the operator to set the impression once and there is no need to reset between repeats.

The pre-register feature ensures that print cylinders are positioned in register before any web is used, saving on materials, ink and also employee downtime whilst the auto register system ensures optimum print quality and minimum wastage. The set up for a typical eight colour machine is as around 10 minutes, with material wastage of less than 12 metres.

Omet’s newly launched integrated Vision-2 register system offer automatic machine direction and lateral direction web control on each print station of the Varyflex or X-Flex press platforms at the touch of a button. Also available on the new wider web XFlex X6 press introduced at Labelexpo Americas this year, the system eliminates operator errors and cuts down on both set up time and waste.