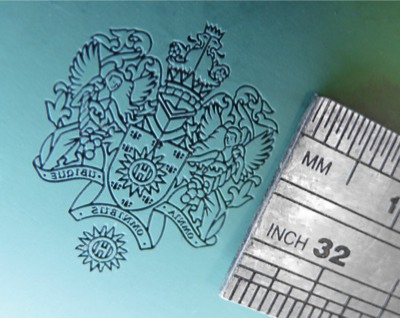

ITR laser engraving by WNRS

Most people believe the point that Darwin was making in ‘On the Origin of Species by Means of Natural Selection’ was that evolution is about survival of the fittest. Rod Hayes claims this is not the case at all, but that Darwin was proposing that the survival of a species for long periods of time is dependent on how successful it is at adapting to changing circumstances. How does this apply to the flexo industry, and in particular, to the printing forme?

The flexo sector is experiencing a sharp shift in technology requiring considerable adaption, and one person who understands perfectly what Darwin was about, is Steve Buxton, sales and marketing director for YRG Solutions, part of the York-based YRG Group. The company is one of the UK’s larger suppliers of across the board reprographic services. He said, ‘We are looking forward to a very exciting 2013. There are lots of changes and fresh approaches taking place in the flexo market.’

YRG Solutions has invested heavily in new technology and plan to continue doing so. Mr Buxton, a rather pleasant urbane Lancastrian not readily given to extravagant gestures, when asked what he thought would be the biggest change likely to take place in the flexo sector during 2013, surprisingly replied with an emphatic, ‘Everything!’

The company has responded to technology developments by investing heavily to ensure its business keeps pace with evolutionary change. Shouldn’t printers be doing the same? After all, under Darwin’s dictum, flexo printers will need to brace themselves for serious bouts of adaptation. Mr Buxton burnished his observation further by pointing out that during 2012, almost every manufacturer of photopolymer material introduced to the market material has been bridled with claims of being ‘new, innovative, improved ink transfer, lower running costs’ and other seemingly endless benefits. When talking with him a feeling grows that he understands his product and knows what he is talking about. He believes there is considerable substance in much of the manufacturers’ claims, and many of the developments have sufficient merit that during 2013 it will be vital for printers, if they wish to continue in business and stay competitive, to invest in new technologies and embrace the advantages on offer. He said, ‘These developments have been taking place at a considerable pace for at least the past three years and the quality of improvements are now beginning to have a major impact. These developments without doubt are a major plus for the flexo industry.’

Steve Buxton sales and marketing director for YRG Solutions

Steve Buxton sales and marketing director for YRG Solutions

Well, may be. Plusses there certainly have been, particularly in the larger formats where the race to innovate has been very strong and the take up of sleeves in all their various guises has been quite marked, but the flip side is that many printers, particularly those who operate presses in the narrower formats, have been more reluctant (if at all) to pursue a significant measure of innovation. It is difficult though, not to have sympathy for printers who are at present marking time – quite literally sitting on their hands in regard to new investment.

Yet ‘Evolution’ says if you do not adapt you die, and predictably in a business environment the reasons often touted are based around the economy, cash flow and so forth, but a quick and hardly in depth survey, suggests that the reasons are far more complex. Mr Buxton claimed, ‘I believe YRG is able to offer the best solution for the customer whether it is our Classic sleeves, ITR sleeves with adaptors or plate mounting sleeves for flat plates.’ This is a claim only a few would dispute at a pedantic level, but to an impartial observer the market place for plates seems fragmented. Mr Buxton observed, ‘The market as far as platemaking goes is in a VHS and Betamax stage and a printer would find it difficult and time consuming to explore all the various offerings available to see which solution suits him best.’

Bite the bullet

Procrastination seems to be the strongest driver behind the dithering that is taking place, rather than capital costs, even if many blame market conditions. It is right to say that printers even if they have the cash generally do not have time to test every solution available and neither can they be expected unaided to carry out the research required to sift out what is marketing hype and what has real merit. Surely some responsibility falls on the shoulders of service providers, such as YRG Solutions and its like. When it was put to Mr Buxton could the company calculate for a willing printer what the effect would be if that printer had used seamless sleeves instead of flat plates and sticky back? His reply was an emphatic, ‘Yes.’

That approach is probably a little way down the road, but to a layman when looking at the overall business picture, the advantage of sleeves and in the round (ITR) imaging seems to be so great, it makes you wonder why printers do not just go ahead and bite the bullet? James Tinker, operations director for YRG Sleeves, said, ‘Many do just that and the issue that holds others back are not necessarily related to money.’

Could a holdback be timidity, or even the frightening pace of change? A printer may be reluctant to invest because he could find he is investing in a technology that may well be superseded within a few years. Darwin would nod his head at the example of both VHS and Betamax, where are either of them now? Such negativity is even more palpable when the pace of change is so great the opposite scenario is more likely to be the case. Any take up on these latest developments will almost certainly allow existing work to be carried out more profitably and to boot, win new orders from clients in ways that have not even been thought of.

The suggestion is driven by the quality and the speed of changeover between jobs that is now possible, and 2013 will see this set to improve dramatically and this will lead to a significant change in the business environment. Making a well considered investment now more likely than not will raise the potential for growth and increased profitability.

YRG Group provides a wide variety of sleeves

YRG Group provides a wide variety of sleeves

Decades of expertise

Another supplier/manufacturer that also recognises this scenario is North West Rollers Services Ltd of Runcorn, in Cheshire. Its managing director, the ebullient Ian Antrobus, has girded his loins to fight this procrastination mindset. He has been fighting the good fight to have flexo printers use directly engraved rubber and elastomer sleeve technology since 1990 and has met with considerable success. By way of example, NWRS is just completing a £200,000 extension to an already quite modern factory with a further five people being added to the pay roll during the past year. One of the newcomers has a rather cheering story to tell and reinforces recent statistic on the job front. An out-of-work welder and father of three young daughters, 30-year-old Mark Ward, cold-called for a job. ‘I wanted a job with a future,’ said Mark and he now has exactly that. At present he is undergoing comprehensive training and Mr Antrobus said, ‘He is a keen learner for sure.’

Sitting in Mr Antrobus’ office, experiencing his enthusiasm and being surrounded by examples of the company’s expertise, a thought crosses the mind: if there is any fighting over sleeve technology to be done Mr Antrobus has a horseshoe in his glove.

The company’s core expertise is working with rubber and the preparing of rollers for a variety of uses across many industries, including laminating, coatings, tinting and gravure impression cylinders to pick a few examples gives the company diversity. Though engraved sleeves for the flexo sector is an important part of the business model, it is clear that the company is far from a one trick pony.

Ian Antrobus, managing director, North West Rollers Services Ltd

Ian Antrobus, managing director, North West Rollers Services Ltd

Mr Antrobus has the confidence that comes from more than 20 years’ experience developing and serving the sector. ‘Rubber is remarkably versatile, it is possible to mill in to the rubber a huge range of attributes and these can include solvent resistance, conductivity, abrasion resistance – in other words virtually any challenge a customer may be facing, we can provide a solution.’

Strong words but a quick look at the specialist stock held supports the claims. The product is milled in the UK giving NWRS decisive and easily managed control of both quality and specification. Milled rubber has a fairly short life in the sense that it can begin to self-vulcanise and oxidise if held too long before use. ‘Quality of our raw material is everything these days, and for directly engraving a sleeve, it is ideal for all applications, particularly where security and a consistent standard of repeatability over many printings is called for,’ said a confident Mr Antrobus.

These attributes gives the company a long reach as well when it comes to the fight to win business. ‘Not only do we have accounts throughout the UK, we have accounts in Europe, USA and the Far East.’ He warms to his main point why printers who have not changed should do so. ‘We can now manufacture flexo sleeves with screen counts and line weights unachievable five years ago. This means designers and those responsible for origination now have a much wider range of options available,’ said Mr Antrobus, welcoming the opportunity to talk about the business he clearly loves.

The take up of sleeves is continuing at pace, whether they be rubber, elastomer photopolymer or even glass fibre compounds. ‘We are always finding new customers, though some are coming from outside the main printing sector,’ said Mr Antrobus talking with his Adaptability Hat on.

Changing perspective

For 2013, in some sectors such as the label and smaller run work, sleeve technology has yet to dominate, there is a mindset issue for which the industry as a whole has to wrestle with. Often the work in this sector is subject to tender. Labels and small cartons are often thought of by the end user as an overhead rather than as an aid to selling products and so strenuous efforts are made to drive the price down. This in turn prompts the printer to view plate costs as a unit element in the overall cost of a specific job, rather than looking at the cost of plates and reprographics as part of say an annual spend in the way he would view business overheads and machinery investments.

This scenario puts printers in a bind; some jobs go well, others run like a sore eye. Moving plate costs from an individual cost against a specific order to part of an overall annual business spend would introduce a different investment perspective through rolling out the highs and lows. Mr Antrobus said, ‘Many jobs are repeats so a printer when pulling a plate off a mandrel or a sleeve will inevitably damage the odd plate. I had a printer who ran an order that was repeated three times and he quickly realised it would have been cheaper to have used engraved sleeves.’

Given that NWRS has been specialising in directly engraved rubber sleeves for more than two decades, it could be argued it has more experience in working out ways for printers to adapt to the changes required to work in an all sleeve environment. Certainly the company has good knowledge of the investment costs and an ability to provide the technical help required to change over to an all sleeve approach. Yet at the narrower end of the market, there tends to be a reluctance to totally commit even though the case is strong that ITR engraved or imaged sleeves provide a more stable consistent and quality of output.

Survival mechanisms

Having a mixed working environment does present challenges. Careful press finger printing should be carried out particularly now the quality of repro and plates is such that setting a press up to run with a fixed colour palette is becoming a realistic proposition. In addition the colour gamut of inks widens steadily as the years go by thanks to quality improvements, so 2013 could be a year for taking a fresh approach to colour management and proofing.

Mr Antrobus recognises these are factors that have to be considered, ‘Direct engraving results in a sharper dot perhaps by around 10% so the gain on the press isn’t quite as much of a headache as it might be.’ The norm these days for flexo repro and the subsequent printing forme must be capable of 170 line screen with highlight tones down to 1%, and of course, having the press capable of reproducing to this level – which means having the ability to manage all the variables, such as ink, anilox engraving, static management, to name but a few.

One solution that provides something of an appealing halfway house is suggested by Grahame Bennett, managing director of Polymount England. Its sleeves have a lifelong self adhesive coating which can be maintained between jobs by a simple wipe down with a mix of isopropyl alcohol and water (IPA). ‘Our self adhesive sleeve can be used on all substrates, and even after long runs, the plate is easier to remove than ones retained by sticky back tape, and the risk of damaging when removing is remote.’ Another plus is that because no adhesive tape is used, variations in thickness from tape roll to tape roll is eliminated, the time taken to change plates is reduced by at least 40%, and of course, the cost of the tape is no longer a factor.

The investment cost is not insignificant, but tests in the US and Europe suggest that if a printer has a high level of reprints capital investment goes positive after four or five runs, but in general it would seem that the money saved in tapes pays for the investment in about a year. However, putting a firm price on this will vary from printer to printer and how each of them run their accounting procedures.

When Steve Buxton suggests that 2013 will be the year everything will change, he probably has printers in mind, but manufacturers of plates and suppliers of services for the flexo sector are also facing some tough challenges. Darwin’s inference is that it is the adaptable species which survive, and YRG and NWRS have this attribute in spades, but this can not be said for some suppliers/manufacturers. Looking at the industry as a whole, a vision comes to mind, one that has a hot tropical sun beating down on a fast evaporating pool in the dry season. Manufacturers and suppliers are like the fish in the pool fighting for the fast dwindling resources of which they are familiar, the fish most adaptable to the changing environment will be the ones that survive and flourish once again when the new rains come. It is far from a given that the ones with the best solutions currently available will be among those swimming after another seasons rains.