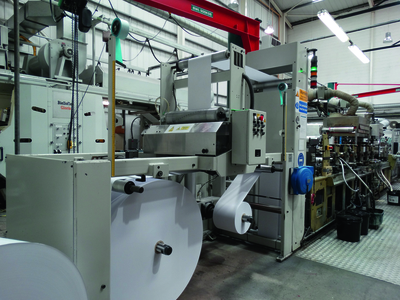

Martin Automatic MBS splice working with Arsoma EM410 flexo press to produce non slip tray mats

When one of the UK’s leading converters of woven and non-woven textiles, Orvec International, looked to improve the productivity of one of its specialist manufacturing lines, it turned to Martin Automatic for a solution.

The product, a printed nonslip tray mat, designed for airlines and other companies requiring a single-use, recyclable item, is manufactured on a sixcolour Arsoma (now Gallus) EM 410 flexo press sline.

The tray mat, which is printed on 80 gsm paper and then coated on both sides with a specially developed water-based lacquer, beforebeing dried at 120 degrees Celsius to create the non-slip finish, poses limitations on the linear speed of the press. So, the only way that Orvec could improve productivity was to reduce downtime caused by manual roll changes and the consequent waste created.

Making savings

Having researched the market, negotiations were opened with Martin Automatic and an MBS butt splicing unwind was installed. After initial teething problems with the splice, caused by the temperature in the dryer, a special 3M tape was sourced and the MBS has run without problems ever since, with some impressive performance statistics, according to managing director, Kevin Stamp.

‘We operate a double day shift work pattern here, and based on the average number of splices per shift, when compared with manual roll changing, I estimate we save 208 hours per year with the Martin, and each splice also saves us around five metres of material. Expressed in percentage terms, the machine has improved our output by between 7% and 8%. And best of all, apart from needing one replacement sensor, it hasn’t failed in eight years of operation.’

New division

Developing the business into new markets is a key area for Mr Stamp, and he explained that the company had recently created a new division within the company, ‘Orvecare’, to focus on healthcare products, such as the adaptation of the non-slip tray mats for use as single-use patient menus, which can be printed both sides and changed each day.

Other possibilities currently under discussion for development include pillow covers, pillows, bed sheets and an emergency blanket, known as ‘Orve+Wrap’, which laminates five-ply non-conductive foil to needle punched felt. R&D at Orvec is seen as the lifeblood of the company, and Mr Stamp is quick to point out that its policy is one of active involvement and participation of staff at all levels.

Looking ahead, Mr Stamp sees great potential for new products within the healthcare industry. He explained, ‘One particular product we are working on is designed to maintain patient temperature during surgery. Medical staff tell us that a one degree drop in body temperature increases the risk of infection by 60%, and can cost up to £12,000 to treat.’ With this and other products it is developing, Orvec claims it can turn a waste cost-neutral facility, like a hospital, into one that recycles its disposable products and shows a cash return.

If the company is successful in growing its healthcare business, from around 2% at present to perhaps 50% of total sales, Mr Stamp foresees the need for more automation and staff to handle the volume of products required. Other developments include the semi-automatic production of table linen that would boost output from one unit every two minutes to 30 units per minute, and reduce labour cost from 35p to 1.2p each.

The process also uses 3% less material. ‘It is not good enough these days just to reduce costs – you have to have something extra to offer, and I believe Orvec is one of the leading pioneers in this market in terms of product development and the use of automation, like the Martin splicer,’ he concluded.

Currently enjoying an annual turnover of around £13.5 million, the company has shown an increase of almost £1 million a year since Mr Stamp became managing director in 2010. With his plans to diversify and grow the company’s portfolio of products, it is hard to see anything other than continued success for the Hull based company.