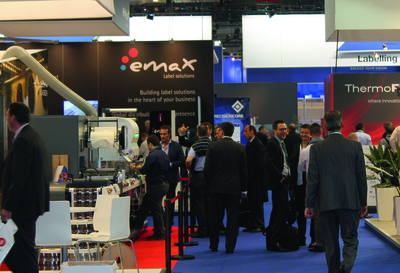

With the report that 31,795 visitors came to the Brussels Expo at the end of September, Labelexpo Europe brought us the positive news that the industry needs, namely that recovery is in progress and that people are buying again. Neel Madsen reports.

Taking over seven halls and covering 31,000 square metres of floor space, the 33-year-old label exhibition was a resounding success as visitor numbers were up by an impressive 11% on 2011. Attendees came from 158 countries to see some 600 exhibitors unveil over 150 new products, including presses, ancillaries and consumables.

Lisa Milburn, managing director of Labelexpo Global Series, said, ‘With the Eurozone now out of recession, confidence and optimism is beginning to return to wider global industry and converters are starting to invest in their businesses again. Continued innovation across the various product groups and strong, sustainable growth in demand across the labelling and package printing market are being translated into sizeable order books.’

Two main themes reverberated through the halls, namely UV LED curing and digital inkjet, but there was no doubt that the flexo market is still going strong as evidenced by a significant number of new presses being introduced by the major manufacturers along with innovations in pre-press, plate processing, inks and curing, anilox technology and much more.

Around the show

AB Graphic International launched new label converting lines and an array of options designed to increase productivity and simplify operation on both its new and existing product ranges. On show was the new Omega SRI label inspection rewinder with servo drive technology, which boasts rewinding speeds of up to 350 m/min and includes fleye-Vision print face inspection.

The show also saw the debut of the company’s DigiLase laser die-cutting system with digital die shop software enabling users to import, create or edit die patterns. The system permits each job to be tested in a virtual machine environment including estimated maximum run speeds before going live.

Alphasonics reported an unprecedented level of enquiries and orders both during and immediately following the show. The Liverpoolbased manufacturer launched its patent pending ‘Active Cavitation’ technology, which follows a number of technological additions to their ultrasonic anilox cleaning systems, including an enhanced ‘supersweeping’ technology for enhanced roller safety and Betasound for comprehensive cleaning for ultra high screen aniloxes.

Chris Jones, marketing manager, said, ‘This year has been the best Labelexpo Europe for a while. Compared to the last Brussels show, the atmosphere was completely different and it is clear that the industry is turning the corner.’

Apex Group of Companies focused on its lightweight series of UltraCell anilox rollers and the ‘open slalom ink channel’ engraved GTTLabel rollers. It also launched a new range of hard- and soft-coated plate mounting and adaptor sleeves.

Apex Group of Companies introduced new sleeve products

Apex Group of Companies introduced new sleeve products

Cheshire Anilox Technology showed the new engraving, MaxfloUV, which has been designed to maximise the inkflow at high speeds when printing with high strength UV inks. Its cell profile helps overcome the common problem of ink spitting.

Daco Solutions showed its capabilities in finishing and had a busy stand with the D350 in focus. This is a single spindle machine fitted with a Daco U350L 1 metre (40 inch) unwind for immediate higher pro- duction output for this class of diecutter, and also features an auto cut and apply web advance system with inter-label cutting for applying the web to the cores at the start of the rewinding process. The die station is strong and is supported down to ground level.

‘There is no other machine out there with a single rewind, auto cut/apply combination and with the job storage system where all relevant parameters for the job can be stored and recalled next time the job runs, reducing makeready considerably,’ said sales manager, Mark Laurence.

Daco Solutions showed its finishing equipment

Daco Solutions showed its finishing equipment

DuPont showcased its latest offering in printing plates, the Cyrel Performance Plates DFP and DSP, formulated to produce higher ink density through a specially engineered surface. The plates can be incorporated into any standard digital workflow. The company also had the Cyrel DigiFlow exposure systemon show. This maintains an exact 1:1 reproduction of image elements on the plate for improved solid ink density. This unit is designed to be used on an ‘as needed’ basis when a hybrid flat-top dot is required. It also optimises the benefits associated with solid screening technologies, such as Esko’s HD Flexo Microcell.

DuPont discussed its products for the flexo industry with visitors

DuPont discussed its products for the flexo industry with visitors

Edale used its ‘Five Hour Production Challenge’ to demonstrate the reliability, versatility and productivity of the FL-3 press.

Running continuous production from 11am to 5pm each day, it produced a variety of short, medium and long run jobs across a range of substrates from 12 micron to 450 micron, as well as a number of additional processes including metallic inks and foiling. ‘Having the machine running continuously was a great selling point, rather than having set demonstrations throughout the day. We really wanted to challenge ourselves and put the machine to the test creating a realistic scenario for potential customers to witness how versatile the machine really is,’ said Darron Shimmons, print and technical manager.

The company was also involved in a range of new machines showing on partner stands. It provides the web transportation system for FFEI’s Graphium inkjet press, which was on the Fujifilm stand, and has collaborated with AB Graphics on the Digicon 3000, a 762 mm wide finishing line compatible with the new HP Indigo 20000 digital press.

Edale’s FL-3 pess was runnng non-stop

Edale’s FL-3 pess was runnng non-stop

eltromat launched the next generation of its twin_check 100% print inspection system. It features new RGB line scancameras with triple line sensors with 4096 pixels each and a line frequency of 85 MHz for improved resolution and image quality.

Esko’s Store Visualizer was brought to life in 3D in the HP hall where visitors got the full immersive experience by donning 3D glasses and watching a demo on a large video wall.

While Esko technology could be seen around the halls on many partner stands, including Cerm, DuPont, Wink, Nilpeter and Mark Andy, on its own stand, it had the full complement of products on show. One new introduction was Full HD Flexo for Labels, which is already operational at a range of flexo trade shops and converters worldwide.

‘We are introducing each version of Full HD Flexo separately to ensure that they accurately and effectively address each application with the right settings and SOPs specifications,’ explained Jan Buchweitz, senior product manager digital flexo.

‘Following extensive customer testing, reviews and approvals, we are confident that Full HD Flexo users will appreciate the benefits this technology brings, most importantly a gravure-like ink laydown and fully ddigitally-controlled platemaking workflow. This innovation will once again expand the reach of flexo printing in the label market to higher quality, more applications and more substrates.’

Exxonmobil introduced three new Label-Lyte oriented polypropylene (OPP) films for labelling applications along with five new Label-Lyte films that were first shown to the market at the American Labelexpo in 2012.

Flexo Concepts was part of a group of US manufacturers that had collaborated on a project aimed at showing the recent advances in flexo printing. Distributed at the show, print samples had been produced using the company’s doctor blades along with Color-Logic’s Design Suite for the images, plates from MacDermid, anilox rollers from Harper Corporation, and inks and coatings from Actega Wit, while Clemson University printed the job on its Omet press at the Sonoco Institute of Packaging and Graphics.

The company also presented the latest addition to the TruePoint range, the Orange doctor blade which promises to last four times longer than traditional steel blades and features a new MicroTip for more consistent contact, and elimination of ink spitting and anilox scoring.

Flint Group Flexographic Products presented the exposure technologies nyloflex NExT and nyloprint NExT to visitors while Flint Group Narrow Web introduced a suite of new solutions including new low migration products added to the Ancora range. In ‘Speakers’ Corner’, experts discussed a range of related topics and answered questions from visitors. The Narrow Web division also won the award for innovation at the Label Industry Global Awards for its EkoCureTM UV LED ink technologies. It was named joint winner alongside co-supplier and development partner, Mark Andy.

Focus Label Machinery introduced the new e-Flex servo press aimed at offering faster set up times, reducing waste and running costs. Available in web widths from 330 to 430 mm and up to 12 colours, the press represents a cost-effective investment with modern technology for high quality printing.

David Lee, managing director, said, ‘We were delighted to see visitor numbers higher than two years previously. Our two new machine launches were well received with orders closed for both the e-Flex and d-Flex presses. Labelexpo Europe has provided the perfect showcase for the new technology. Our customers’ enthusiasm has shown they are now ready to invest at a time the global economy is recovering. Without doubt more orders will follow.’

Focus Label Machinery’s new e-Flex servo press

Focus Label Machinery’s new e-Flex servo press

Gallus presented its Print Concept, in effect a small label printing shop, which drew in visitors to demonstrate how digital and conventional manufacturing processes combine to save time and money in label production. It also demonstrated the benefits of UV LED curing on a Gallus EM 280 press, producing labels using the latest UV LED inks from Siegwerk and lamps from Phoseon. The company said that its first conventional press with UV LED curing is about to go into beta testing.

Christof Naier, vice president sales and marketing, said, ‘For Gallus, it was an excellent show. In total we held 61 live demonstrations with over 30% more visitors compared to 2011.

Particularly the Print Shop concept including the highly flexible near-line solution comprising the Heidelberg Linoprint L digital printing system and further processing on the Gallus ECS C generated a lot of attention.’

Gama Srl introduced its VIS-G26 system, which incorporates a measuring device with ‘tuning forks’ for improved ink viscosity and temperature control. The device measures the viscosity of inks, coatings and adhesives, and will sound an alarm if registering any deviations from the set parameters. It can be used with both solvent and water-based inks.

GEW showed the E2C low energy UV curing system, which now features an electronic control unit that promises reductions of up to 46% in power usage and carbon footprint.

The Rhino control package includes new electronic power supplies of military- grade design, with a touchscreen interface and software package that facilitates maximum operating efficiency.

The company also offered the latest in UV LED curing which is compatible with the Rhino control technology for use in hybrid UV systems.

The LED technology could be seen working at the show on GEW’s novel ‘Magic Carpet’ precision lab unit, designed for the development and optimisation of LED ink formulations.

The system transports ink samples and power measurement devices accurately at the desired speed so that curing tests are always repeatable and yield reliable results.

A first time exhibitor at the European show, Harper Corporation of America provided demonstrations of the Phantom QD ink proofing system and presented products from the newly developed HEX division.

This branch of the company focuses on plate and bridge sleeves that are in compliance with OEM specifications and provide an enhanced level of support to customers via innovative features, such as a patent-pending replacement notch system. It also displayed its HIVE, or high imaging volume engravings, anilox roller series.

‘We were impressed with how many attendees participated in Labelexpo Europe,’ commented vice president of sales, Alan Rogers. ‘This was the perfect event at which to lay the foundation for our new strategy to support clients in Europe and throughout the rest of the world. We have certainly been able to use this event to educate industry leaders about our new HIVE products and HEX division.’

Hybrid Software launched Cloudflow, which promises to ‘introduce a totally new ‘workspace’ concept to the web-enabled production environment.’ A web-based portal solution, it has been built using HTML5 technology for compatibility with major browsers, tablets and smartphones, and is of a modular design.

‘The majority of existing workflow systems are constricted by being modelled on outdated core technology or architecture that is simply not designed with the required demands in mind,’ said chairman Guido Van der Schueren. ‘With the extensive consolidation that continues to occur in all graphic arts segments, many companies are global suppliers with multiple locations. A cloud-based workflow system that is accessible to all locations is exactly what these graphic arts suppliers need. Cloudflow has already been proven in the labels and packaging market by companies such as Xeikon and Oki Data.’

IST Metz unveiled its new ‘LED prepared’ concept, which offers theoption of converting an up-and-running UV system from the MBS-6 series to UV LED technology. This is done by keeping the outer housing and replacing the MBS-6 unit with an LED cassette unit.

The LED unit was developed in conjunction with IST partner Integration Technology Ltd and was demonstrated on a narrow web flexo press on the stand. Dirk Jägers, managing director, said, ‘We realise that at this point in time UV LED technology is a very large investment for most printers. Our advice is to stay with traditional UV curing for the time being, but invest in our system, which gives the option to change to LED in the future.’

The Brussels Expo welcomed nearly 32,000 visitors

The Brussels Expo welcomed nearly 32,000 visitors

JM Heaford reports an excellent response to its mounters and sold all the machines on show at it stand.

Visitors could see demonstrations of the Narrow Web FTS Mounter, which was nominated in the innovation category at the Label Industry Awards. Sally-Anne Heaford said, ‘Heafords had its busiest ever Labelexpo Europe at its ninth consecutive show. The award winning and innovative FTS Narrow Web Plate Mounter generated huge interest with over 200 visitors to the stand. The ease of use, repeatable accuracy and speed offer buyers the alternative to automation without the price tag.’

As a restructured company, Kodak came out of Chapter 11 all guns blazing with announcements ofpartnerships with Bobst and Uteco Converting. While the exact nature of the agreement with Bobst is still under wraps, the deal with Utecosees Kodak’s Stream inkjet technology combined with Uteco’s wide web press experience to unite flexo and digital on one press.

Over the last five years, the company has now sold over 300 Kodak Flexcel NX systems and is now focused on applications and maximising the potential of the technology.

Direct engraving of sleeves in the form of the Flexcel Direct System continues to evolve, said global marketing manager, packaging solutions, Emma Schlotthauer, who also emphasised the importance of working closely with suppliers of ink, anilox rollers, and other consumables.

Together with the Kodak Spotless Flexographic Solution, the Flexcel NX system was also demonstrated when Kodak, MPS and Reproflex3 teamed up for a live presentations to show visitors how to ‘Do More With Less’. With pre-press delivered by Reproflex3, live jobs were shown running on the MPS stand.

KPG Europe had the extended version (520 mm) of its Euroflex press range. As with the existing 260 and 400 mm web widths, the new wider press is available for dual and single-pass production, using a single central impression drum.

In addition to its existing range of presses with UV curing, the company is now able to supply presses configured with hot air drying and IR systems. Manufactured to meet ATEX approved standards, the new presses are suitable for use with solvent, alcohol and water-based inks.

Mark Andy celebrated the sale of the 250th Performance Press, which was the P5 on its stand due to be installed at a Spanish company after the show. It had more cause for celebration as its ProLED technology was given the innovation award at the Label Industry Awards held on the first night of the show.

The show also saw the launch of a new advanced print platform specifically for film and flexible packaging applications named Versa Max. This combines the film printing expertise of Comco with Mark Andy’s own engineering designs to offer a solutionfor short run film and flexible packaging work.

The Versa Max is available in 560 or 660 mm web width and has a maximum production speed of 366 m/min. It has a print repeat range of 254-813 mm and is capable of handling substrates from 12 micron monofilms to multi-layer structures for flexible packaging, with inline lamination. The web transport system is fully servo driven, with the plate sleeves mounted on an in-station plate mandrel for easy changeover. For water-based or solvent inks and coatings, there is a hot air impingement drying system, with options for UV, UV LED or combination drying and curing.

Martin Automatic enjoyed a highly successful show, according to marketing manager, Craig Thomson, who commented, ‘There is no doubt this is the leading global show for the narrow web industry, and it was a rewarding experience to see the industry in such a positive mood – this can only be good for everyone moving forward.’

Welcoming visitors from 39 different countries to its stand, the company had enquiries and customers coming from as far afield as Australia, China, Japan, Indonesia, and the Indian sub continent, as well as the Middle East and North and Central America. Mr Thomson said, ‘We have a large number of requests for quotations and follow-up visits to do. Fittingly, the exhibition closed with the final visitors to our stand signing a contract for two machines.’

Meech showed its complete static control and web cleaning ranges, including the recently launched Hyperion static elimination bars, 971PIS and 929IPS, and CyClean, its latest non-contact web cleaning system, which is capable of removing contamination to below 1 micron and incorporates fluid dynamic principles to deliver higher levels of cleanliness for label printing applications.

Mitsubishi HiTec Paper said visitors showed great interest in the re-launch of Supercote, the premium cast-coated label paper, which is available in two grammages and in a wet-strength version. Marketing manager, Ralf Buhl, said ‘We would like to thank all our visitors for the many varied and interesting conversations and discussions which will hopefully lead to new relationships as well as further development of old ones, and look forward to Labelexpo 2015!’

MPS reported a successful launch of its new high performance EB flexo press and the extended MPS EF multi-substrate press line, with three versions ranging in price level and level of automation. The stand saw visitors from over 90 different countries and the diversity of geographical markets was also reflected in the signed orders received, including a contract for a new MPS EF press from a printer in Uzbekistan, an order for an EF-APC Advanced press from a printer located in India, while the new EB press on stand was sold to Hine Labels in the UK. Eric Hoendervangers, commercial director and co-founder, said, ‘The new EB flexo press is the most costeffective press ever built by MPS.

Designed for printing and converting self-adhesive labels, it is a solution for label printers in all market segments. With a doubling of visitors at the MPS booth, high-quality contacts, and surpassing show sales goals with additional sales still under negotiation, MPS reports a very successful show.’

Nilpeter’s famous bell rang out 24 times during the show signalling the sale of each new press. Jakob Landberg, sales and marketing director, said, ‘Receiving its European debut was the sleeve-based FA-4* for highend labels and packaging, and the high-performance FB-3 UV flexo press. Two years ago there was less hype and it was not such an exciting exhibition. Now the hype is back and the show is vibrant and positive. This year we have had customers come on the stand and have enthusiastically made a purchasing decision on the spot. Instead of concentrating solely on efficiency, the emphasis this year has been on capacity. Heavy metal is back!’

Nilpeter press demonstration

Nilpeter press demonstration

Nuova Gidue introduced the new M5 Excellence flexo press, which is based on the concept of ‘Never Stopthe Press Running’. The company said that this is achieved by the print cylinders being prepared for the next job, while the current one is still printing.

The automatic exchange of printing cylinders (ExcelPrint) is integrated by the Digital Flexo HD cameras, which recognise the new job and adjust pressure and register settings digitally without manual intervention.

The press is mounted with two die-cutting units, which switch from the old to the new job without stopping (ExcelDie), while all die-cutting pressure, pre-register and register operations are digitally performed by the Gidue DigiGap technology which automatically registers the thickness of the substrate and adjusts the die-cutting unit accordingly.

Omet is celebrating its 50th anniversary this year and the show was the culmination of the festivities.

It showed a multi-process press combining flexo and offset with sleeves in the form of the XFlex X6. This combined four flexo stations with five offset units with sleeves, the latest innovation from the Italian machine manufacturer. Live demonstrations showed the printing of a production label courtesy of Campari and flexible packaging on PP+PE films from Ferrero snacks. The company said that customers showed particular interest in presses with complex configurations proving their greater possibility in capital equipment expenditure.

Antonio Bartesaghi, managing director, said, ‘Again, Omet offered a great performance, the company showed to be highly professional and with products of excellent quality. In its specific markets, and compared to its direct competition, Omet is moving up, and is today a brand recognised and appreciated by the entire audience of customers – real and potential – including leading multinationals.’

Phoseon’s UV LED technology could be seen on inkjet and flexo OEM stands throughout the show.

Stacy Hoge, marketing and communications specialist, said, ‘UV LED curing technology was a hot topic at Labelexpo Europe this year. Our high amount of booth traffic from OEMs, ink suppliers and end users interested in this curing technology was really impressive. UV LED for digital inkjet has been gaining worldwide adoption for several years and, there were more than 15 stands running UV LED for digital inkjet at the show. The advancements in UV LED for flexographic printing were also quite impressive. The live flexo presses running at Labelexpo prove that it is a viable technology for flexographic printing today.’

Prati and Ritrama had joined forces to present their new innovative ‘Core Linerless Solutions’, which consist of a PSA film from Ritrama and the VEGAplus Core finishing system from Prati. The material is a thin PP film on a siliconised filmic liner, which is printed on a conventional press then transferred to the finishing line where the web is opened and the backing liner folded over to form a laminating top layer protecting the printed surface and then die-cut.

Prati celebrated its 40th anniversary with a party where sales director, Chiara Prati, gave a speech saying that ‘never before has there been a time like this for the company, when all resources are concentrated on the future, a future in which we see ourselves not only strengthening our leadership in the segments we already operate in, but also launching into new areas and taking up increasingly more stimulating challenges.’

Prati celebrated its 40th anniversary

Prati celebrated its 40th anniversary

Pulse Roll Label Products presented a range of new product launches, which included UV flexo inks, UV curable varnishes for wine labels and screen varnishes for high build, tactile or braille applications. Managing director, Gary Seward, said, ‘This has been our most successful Labelexpo show to date and has done much to increase international brand awareness for the company.

We have many high quality leads across a broad range of ink products to follow up as well as enquiries that offer the potential for appointing new distributors to expand our global presence and representation around the world even further. We have already reserved our stand for 2015.’

Railex reported making over 200 contacts during the show where it showed its range of storage solutions,including dies and printing plates. John Maddison, marketing, said, ‘We believe that the label industry can benefit massively from cutting down their storage space and that Railex provide just that solution. Storing printing materials in our specially designed files leaves more room for precious machinery, and the way in which it was stored means manual access is speeded up, meaning a vastly increased work rate.’

Rogers Corporation showed its range of R/bak cushion mounting tapes for reduced and eliminated gear banding, shock absorption, reduction in dot gain and improved print quality.

RotoMetrics showed its Accu-Series of flexible dies, which has been optimised to just four products that cover the entire range of applications, from abrasive materials to ultra thin liners. The AccuSmart die is the economical choice for short to medium runs ideal for standard liners. AccuPrime is a popular choice aimed at thinner liners down to around 30 microns, while AccuStar UltraFilm accommodates very tight plate tolerances for very thin liners down to 12 microns. The final product is the AccuStar Life developed for very long runs and abrasive materials and coatings.

Sun Chemical launched two new white inks. SolarFlex Neutron White is a high opacity UV flexo first-down white intended for the printing of labels, tags, sleeves, tickets and other narrow web applications where high opacity and whiteness is required.

SolarFlex Sleeve High Opacity White allows customers to match theopacity of other UV flexo sleeve whites but at a lower film weight. It is a UV flexo last-down ink intended for reverse printing of shrink sleeves and other impervious substrates where high opacity is required, including wrap-around labels, clear, paper or board substrates and other filmic applications.

Jonathan Sexton, marketing director narrow web and screen, said, ‘Sun Chemical had an extremely successful show with 40% more leads compared to 2011. At this year’s show, we displayed all of our different capabilities for the narrow web label and packaging market, which resulted in more visitors at one time than we’ve ever had at a Labelexpo show. SolarFlex Neutron White generated great customer interest generating more than 100 inquiries.’

tesa offered visitors a short course in how to choose the correct foam hardness using its tool entitled, tesa Foam Advisor. Jürgen Dostal, international product manager, said, ‘Leads generated exceeded 25% plus in comparison to stable numbers in the years before.

As well as a new foam hardness in the Steelmaster mounting tape range, tesa 52018 Softprint x-Soft, visitors were especially interested in a brand new tool called tesa Foam Advisor. According to the plate type, thickness and design to be printed the tool advises on the correct foam hardness to be used for optimum printing results.’

Substrate specialist Thomas Graphics has found its niche supplying printable polymer based materials to the narrow web industry. Managing director, Nanette Thomas, said, ‘We work closely with narrow web printers, helping them get into flexible packaging as this is a market they have little knowledge of. We can ‘hold their hand’ and show them how the flexibility of narrow web printing can be used to great advantages in short run flexible packaging.’

The company, which has formed a strategic partnership with Polish film manufacturer Eurocast, managed by former Gerhardt CEO Klaus Damberg, has a wide portfolio of synthetic polymer-based papers, flexible film and rigid films for all types of applications, including bags, labels, tags, wraparound and inmould labels, shrink films, lidding films, flow packs and sachets. New products introduced at the show included SYN-TAG and SYNCOAT synthetic papers for digital printing, SYN-SHRINK shrink film, and SYN-LID, a range of multilayer lidding films.

Troika Systems had two new products to offer. The company has done much research into the standardisation of anilox volume measurement and has now developed Volumetric Calibration, which can be used with its Anilox QC tool. It also launched the Print-II-Plate HD handheld dotmeter for comparison of dots on masks, plates and printed material.

Phil Hall, managing director, said, ‘Labelexpo Europe 2013 exceeded all our expectations with over 50% growth in qualified leads over the previous exhibition. Knowing there is now an absolute volumetric standard for anilox measurements was without a doubt a big draw for many printers and also for the majority of anilox manufacturers. The launch of the new P2P HD QC tool for platemakers and printers was also very positively received with serious leads coming from over 24 countries.’

A first time exhibitor Uteco Converting was on the stand of its business partner Advanced Machinery NV, which is also the distributor for Re, Helios, ACE, Ferrarini & Benelli, and partners with Laem Systems. The show also saw the announcement of a cooperation agreement between Kodak and Uteco.

In addition to showing its established range of SuperCut flexible dies, cylinders and steel rule dies, Wink launched the ProShift technology, supported by Esko, the adjustable anvil cylinder GapControl, as well as the MCR coating for flexible dies and a completely revised version of the ‘ABC of cutting tools’. ‘We are more than satisfied,’ said sales director, Detlef Geske. ‘We have noticed an enormous increase of leads compared to 2011, which already had been very successful, and we were able to convince all along through our product range.’

Vetaphone introduced a new operator friendly solution for its VE1A corona treater station, which involves mounting an interface on the treater itself in the form of a touchscreen device. This gives the operator easy access to control the treater and eliminates the need for mounting an external control panel.

The company said that it is continuously working to make its solutions as compact and easy to use as possible for both end users and manufacturers in the narrow web industry and that the reception of this new feature had been very positive. Many OEMs have already expressed the desire to have this option on all future deliveries.

Xeikon had the ThermoFlexX plate processor on stand in two sizes, the 30 and the new 80. The new larger size, which was launched at the show, can process plates up to 1270 x 2032 mm in size, in thicknesses from 0.73 to 6.35 mm.

The company has recently been acquired by Bencis Capital Partners and Gimv-XL, and Wim Maes has returned as CEO, taking up the position just a few days before the show.