Transforming the packaging industry with colour management. By Patrice Aurenty, business leader, colour management at Sun Chemical.

Brand owners are constantly looking to secure a productive, dependable and profitable value chain from their suppliers. Central to this value chain is the package printer, and for the package printer, consistency of colour output is one of the most critical factors. That and being logistically located for ease of supplying the package to the brand owners’ facilities.

Due to the high cost of printing technology, as well as the amount of space and training required to operate it, colour specifications communicated from the brand’s designers have traditionally been handled by experts within the value chain.

Harmonisation of colour

Naturally, brand owners strive for harmonisation of colour across all substrates, applications and geographies to communicate their brand equity consistently to consumers on a worldwide basis. However, this is often very difficult to achieve, not just in terms of the accuracy of colour management itself, but also due to regulatory issues, logistics and economics all being incohesively managed.

In addition, the complexity and high cost of investment in new product development also acts as a barrier to innovation, which is so vital in the competitive FMCG market. This is especially significant when taking into consideration the cost of reworks required to secure colour consistency to safeguard the integrity of the brand.

In the packaging industry, regardless of the vertical market, the same business issues float to the surface in most discussions with brand owners and their suppliers. Brand consistency across formats, substrates and geographies is a business critical objective, tied in with the desire to streamline processes, introduce efficiencies where possible, manage cost by eliminating waste, and accelerate time to market.

Without a doubt, colour inaccuracy and inconsistency can be major causes of delays and bottlenecks in the process. The universe of different individuals involved in reviewing and approving colour for a particular job can be vast and geographically disparate, making it hard to communicate effectively and get a grip on something as slippery as ‘correct’ colour.

Of course, the packaging community has taken steps to take out the guesswork around colour. In the field of process colour, that has mainly been a question of introducing and enforcing standards such as ISO for the participants in the supply chain to adhere to.

The difference is that the colours are created by mixing them on the press rather than pre-mixing as a spot colour. Here the requirement is for the ink manufacturer to produce inks to the colour specification set that meets the standards for the appropriate printing technology in ISO 2846.

Then the converter must set up and control their press in line with ISO 12647 and profile the press so that the colour created from it is both measurable and predictable. This enables the creation of a good quality and consistent image that matches the original brand owner design.

Colour managemnet expert, Patrice Aurenty

Colour managemnet expert, Patrice Aurenty

Science of colour

Where spot colours are concerned (and that is often a key consideration for brand owners with their brand- or product-specific colour palettes), the challenge has been greater. The Pantone book remains the default reference for spot colour. Yet in practice, ‘colour management’ is often a mix of gut feel, operator experience and the somewhat inconsistent use of measurement tools and samples of uncontrolled origin representing the standard where the Pantone guide is unavailable or not specified in the first instance.

When trying to map colour management processes in many packaging supply chains today, the picture is pretty chaotic, with inter-communication going in many directions, and often around in loops of approval and re-approval.

This is a recipe for error, inefficiency and excess cost.

Of course, there are readily available software tools for colour management, but the challenge remains that they are often deployed inconsistently by individual links in the supply chain, looking more like disconnected islands of solutions than an industry standard reference.

What is more, they may be supplied by small entrepreneurial software developers with good technical credentials, but without the infrastructure and expertise to support the deployment of products across large global companies and multiple disciplines (design, pre-press, converter, etc).

While colour management software might remedy the problem at one site, it fails to address the wider issue. In order to take the guesswork out of colour in packaging, every participant in the supply chain must be working from the same, scientific point of reference: the spectral data of a colour.

The DNA of colour

Happily, there is a remedy for the chaos, and the prize is worth having. Far greater efficiency, streamlined product delivery, and optimal colour accuracy and consistency across different packaging types, and from country to country. Colour is not subjective; every colour that can be printed can also be measured, and its characteristics stored as a spectral curve that acts as the ‘DNA’ of the colour and serves as an exact specification for further reproduction.

There is a supporting system that enables printers to reproduce any colour as faithfully and efficiently as possible, whether on paper, board, film, plastic or any other substrate that can be thought of.

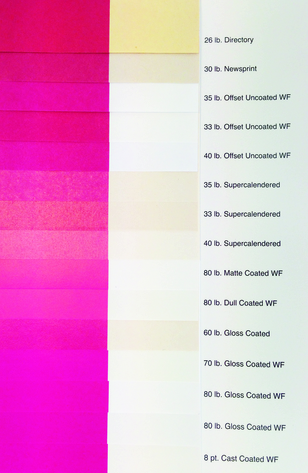

Library of substrates shows the colour variance

The key for such a system is to develop multiple libraries of colours that cover the majority of substrates used in the packaging industry, including corrugated kraft, transparent and white films, laminated films, carton board, paper and labels. These libraries can capture the spectral curves of any colour on the relevant substrate – from a physical print – and hold it in a database on the cloud, which can be referenced at each step of the packaging workflow when a brand owner needs to reproduce that colour. The additional key enabler is a digital color communication tool that can link every part of the packaging workflow and share this colour DNA with every participant.

The brand owner specifies the right colour digitally. The designer creates the design file using that exact same colour signature. Pre-press adapts the file to the specific printer configuration based on that same colour spectral curve. The ink manufacturer matches spectrally the right ink to that digital colour specification. The printer ultimately reproduces the colour on the final product and controls its quality by comparing directly to the original colour spectral curves, as specified by the brand owner. This closes the loop for a seamless colour approval process. Furthermore, this type of system allows everyone to work from the precise and unique colour definition stored on the cloud and enables users to operate seamlessly in a fully digital workflow. Accurate output can therefore be produced that will match the original specifications established from real colours on real substrates.

This tool has the scope to remove the margin for error in colour reproduction from one packaging material to another, and to bring about a far greater consistency through brand families and across multiple territories where substrates are often inconsistent.

Full implementation

However, the key to true colour management is to deploy this science right through a particular packaging production workflow by ensuring that all participants in the process are working, communicating and ultimately printing with the same colour data. This type of solution completely overturns old colour management practices by delivering significant, quantifiable improvements for brand owner and their suppliers.

Total colour management in packaging is no longer the elusive Holy Grail – the data and the systems are already here that make it a reality. The packaging supply chain has actively embraced the potential of digital technology in so many other areas of the workflow, but colour somehow remains a magical element which too many packaging printers still prefer to leave to visual evaluation by ‘experts’- with a heavy cost to all parties.

By applying logic and science to the magic, digital colour management has the power to answer the prayers of brand owners.