BST eltromat’s iPQ-Check provides 100% inspection

The use of inspection systems can make an important contribution to ensuring customers’ high quality standards and safety requirements, are met by the printer. Michal Lodej looks at the options available.

With some print productions running up to speeds of 500m/min, print defects can get expensive in a very short time. A good web inspection system will help a printer to identify these problems on the press while the job is running, keeping those costs down.

There have been some changes in the web inspection market recently with Baldwin Technology Company acquiring PC Industries, QuadTech and WPC late last year. Together they form a new company called Baldwin Vision Systems.

Commenting on the mergers, Craig Du Mez, the man in charge of the branding, PR and communications for this new company, said, ‘Along with web printing controls, the resulting combination of businesses and technology will represent the industry’s most comprehensive portfolio available for print process automation, inspection and related services. This will give printers the ability to choose between multiple options in a product class and select the option that best fits their specific need and budget.’

The mergers have given the new company a wide range of products to play with, the leading inspection unit being the Guardian PQV, which provides 100% inspection in a ‘feature-rich’ system. The unit can be used for converting wide and narrow web applications and can fit onto any press or slitter/rewinder, providing high power and accuracy through defect detection, OCR/OCV, barcode grading and verification and dimensional gauging.

Also on offer from Baldwin is the Guardian OLP, a PDF proofing and off-line inspection system that can automatically find and highlight differences in print quality from an approved master image. The Guardian OLP can compare a one-up electronic file or scan to a multi-up electronic file or scan. This system will detect printing defects, such as missing or extra print, pre-press errors, plate defects and colour variations.

The company also has the Graphic-Vision 500 Series web viewers, which feature long-lasting LED lighting, making them perfect for high-speed applications. The GV-530 offers advanced multi camera, programmed and combination positioning, in addition to automatic lateral and linear scanning.

While the cameras are capturing an incredible amount of information on what is being printed, this still needs to be processed. The Baldwin Data Central for inspection monitors, audits, stores and generates reports of both live and historical data to quality control. This system makes printing more traceable and accountable to the production process, adding a whole layer of intelligent quality control information to a closed loop print inspection. Data Central gives users the ability to set quality standards based on a particular customer’s specification.

Check yourself

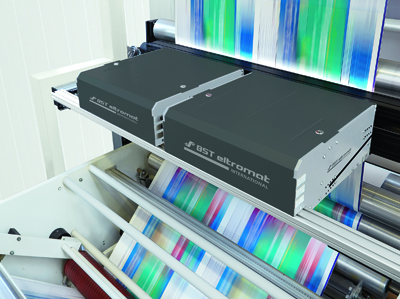

BST eltromat International has a wide range of different products for the task of web monitoring, however it is the iPQ-Check, a module of iPQ-Center, which is for 100% inspection. As an intelligent tool for quality management, the system combines 100% print inspection with high-quality web monitoring throughout the entire print format. Typical areas for implementation of the iPQ-Check include packaging printing, decorative prints, wallpaper printing, and label printing. It also enables the machine operators to identify defects on rewinders, cross cutters, and longitudinal cutters.

iPQ-Check is suitable for web widths of up to 2800mm and machine speeds of up to 1000m/min. High-performance line scan cameras deliver detailed colour image data across the entire print format, and log the production results. According to the company its algorithms guarantee complete, reliable control, so that sources of defects can quickly be located and eliminated. The system is also capable of distinguishing between process-related and sporadic errors in this context.

A good web inspection system can identify defects quickly

Other modules from the company include iPQ-View for web monitoring, iPQ-Spectral for inline spectral colour measurement and iPQ-Workflow, which integrates the three quality assurance systems in a closed quality assurance process.

BST eltromat pursues an all-inclusive approach to print production by integrating production-assisting, third-party software tools in its workflow, also including pre-press operations. The four modules of the iPQ-Center cover virtually the entire range of demands on quality assurance in printing processes. The three quality assurance systems, iPQ-Check, iPQ-View and iPQ-Spectral, each assume different quality assurance tasks and each system can be used as a stand-alone solution where required. In practice, however, two or all three of the systems are usually integrated into all-inclusive solutions for quality assurance and configured for the specific customer.

Out on show

The recent Print4All, held at Fiera Milano from 29 May to 1 June 2018, was the site of new technology launches from across the industry. Web inspection was no different with Grafikontrol giving two new products, the Lynex C/S and Matrix C/S, their first public outing.

Dedicated to 100% inspection and detailed statistics for coating, varnish, cold seal, the Lynex C/S and Matrix C/S join the company’s TQC-360 range.

Lynex C/S is a 100% inspection system expressly developed for quality control of cold seal or transparent coating/varnish. When integrated with Lynex or Progrex systems, the front-to-back image can be superimposed on a 55 inch monitor.

Matrix C/S consists of two opposed cameras and the perfect synchronisation allows the operator to check register between front print and a glue or cold seal applied on the back.

‘In the first few months of 2018 we have already installed a dozen Lynex C/S systems in various countries around the world,’ said Paolo De Grandis, sales manager and partner in Grafikontrol. ‘The ability to integrate systems has been the key element that customers have appreciated. Integration is at the heart of our TQC-360 concept and fully meets the specifications of the Industry 4.0 project. Grafikontrol’s products have a modular structure so that customers can start with a configuration and implement it at any time.’

Meeting the demands of pharmaceutical labels

In 2016, Eson Pac from Aesch, Switzerland, was in conversation with a large international pharmaceutical group for the further production of labels. In order to secure the order in the long term, an extensive list of criteria for an artwork and off-line inspection was expected to be fulfilled. Based on the use of an EyeC inspection system, Eson Pac guaranteed both the required artwork inspection in the pre-press stage as well as the sample inspection during the entire label printing process. The EyeC Proofiler 400 DT off-line inspection system in combination with the Proofiler Graphic option fulfilled all the criteria required by the pharmaceutical group.

The EyeC Proofiler 400 DT performs a comprehensive check of samples against one or more approved PDF files or a reference print. The Proofiler Graphic option makes the graphic inspection from a printed PDF file in pre-press possible.

Eson Pac will position itself even more strongly in the field of pharmaceuticals and promises further orders with the use of the inspection system, which complies with ISO 9001, GMP, GAMP 5 and 21 CFR Part 11.

For six months, the EyeC system has now taken over the pre-press artwork inspection as well as off-line random sample inspection during label printing, thus ensuring compliance with the high quality standards of Eson Pac.