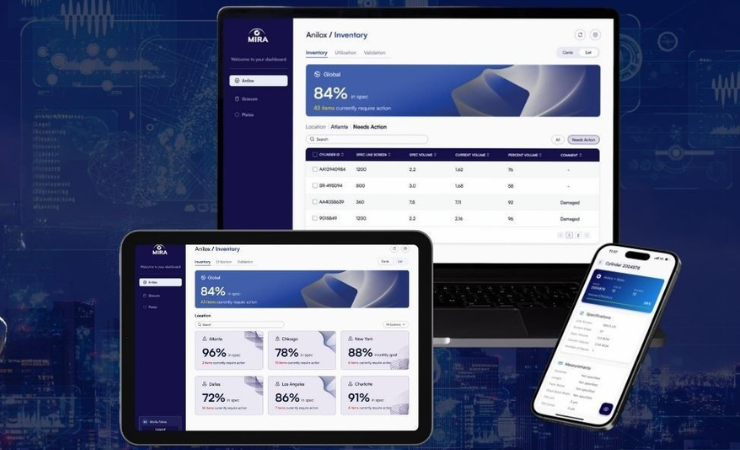

Manufacturer of inspection and measurement systems MicroDynamics has launched MIRA, a cloud-based intelligence platform designed to help Veritas users access and analyse anilox data across multiple sites. The platform aims to improve data visibility and decision-making for printers, suppliers, and partners through real-time access to inventory and inspection information.

“MIRA is an Industry 4.0 solution built for the next generation of the print workforce,” said Carl Powell, chairman of MicroDynamics. “For the first time, printers can see anilox data across multiple sites in one connected, user-friendly view, automate what once required hands-on oversight, and put their data to work, manually or automatically. This is not just measurements – it’s optimised intelligence for the future of the industry. I’m extremely excited for the power MIRA will bring to our customers and partners.”

The platform provides secure access via web and mobile devices, allowing users to share and act on data from anywhere. According to MicroDynamics, MIRA offers tools for quality control teams, maintenance staff, and managers to track roll history, monitor instrument usage, set alerts, and streamline cleaning and inventory workflows.

“Anilox inspection is entering a new era,” said Brent Zurcher, director of operations at MicroDynamics. “With MIRA, printers, suppliers, and partners will finally have the visibility and collaboration tools they need to make smarter, faster, data-driven decisions across multiple sites and inventories.”

For suppliers, MIRA allows shared analysis of anilox data, aiming to improve communication and collaboration with customers. Features such as automated alerts and the use of Veritas measurement data support more proactive customer service and issue resolution.

MicroDynamics also introduced MIRA Robotics, a new integration that enables fully automated operation of Veritas inspection systems. Designed to work with a variety of equipment – including printing presses and laser anilox cleaners – MIRA Robotics supports in-process measurement without the need for manual control.

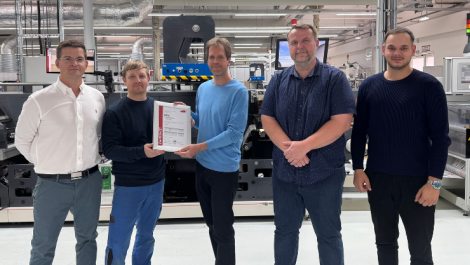

The robotic integration is already being used in BW Converting’s PCMC Meridian Elite+ and TWEN’s TAC_M_Micro laser anilox cleaners. In both cases, Veritas inspection is built into the cleaning systems, allowing users to clean and inspect anilox rolls in a single step.

According to the company, the launch of MIRA and MIRA Robotics marks a step toward automated, closed-loop quality control systems across the printing supply chain. The new platform builds on MicroDynamics’ existing technologies to support more efficient, connected operations.