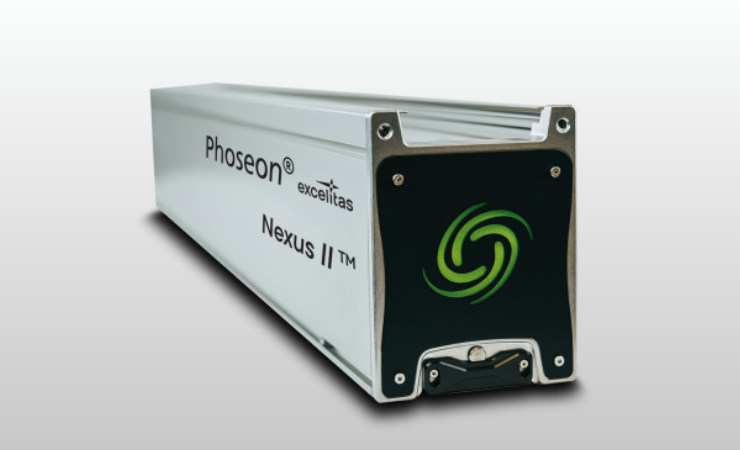

Excelitas has released its new Phoseon Nexus II UV LED Curing Platform, designed specifically for flexographic printing applications. The company said the system delivers significant improvements in reliability, performance under high-temperature conditions, and cooling efficiency – thanks to a newly available high-airflow model.

The company stated that a major advancement introduced with the new system is Nexus DataHub, a cloud-based monitoring solution that enables both real-time and historical access to critical system data. Designed to support the digital transformation of industrial manufacturing, DataHub allows users to monitor UV LED curing performance alongside overall machine functionality from any location, using a secure web portal or mobile app. This remote monitoring capability aligns with the principles of Industry 4.0, helping manufacturers improve operational efficiency and make more informed, data-driven decisions.

Users can access detailed performance metrics such as UV intensity, system speed, energy consumption, and machine status, with data available in intervals ranging from 30 seconds to one hour. Nexus DataHub operates continuously, offering full visibility into system performance 24/7. Additionally, customers using the platform benefit from exclusive service and repair discounts.

Available in both air- and water-cooled configurations, Nexus II systems come in a range of sizes, including 300mm, 375mm, 450mm, 525mm, 600mm, and 675mm, making them suitable for a variety of flexographic printing applications. With the highest total UV power output in its class, Nexus II enables printers to achieve greater throughput and efficiency than ever before.

With the launch of Nexus II, Excelitas continues to drive innovation across the flexographic printing industry, combining robust engineering with smart digital capabilities to meet the evolving needs of manufacturers around the world.